Ultimately, neither PVD nor plating is universally "better." The ideal choice is determined entirely by the specific demands of your application. PVD (Physical Vapor Deposition) excels in creating extremely hard, durable, and wear-resistant surfaces, whereas traditional electroplating is often superior for cost-effective corrosion resistance and classic decorative finishes.

Choosing between PVD and plating isn't a matter of good versus bad, but of aligning the process with your primary goal. PVD is a high-performance physical process for durability, while plating is an established chemical process often optimized for protection and aesthetics.

What is PVD (Physical Vapor Deposition)?

Physical Vapor Deposition is a vacuum coating process that produces a thin, high-performance film on a substrate. It's a fundamentally different mechanism than traditional wet plating.

The Process at a Glance

In PVD, a solid source material is vaporized inside a vacuum chamber. This vapor then travels and condenses onto the part, forming a very thin yet dense and strongly bonded coating. Think of it as a form of "atomic spray painting."

Key Characteristics

The resulting coating is often a ceramic or metallic compound. This gives PVD its signature characteristics: exceptional hardness, low friction, and high resistance to wear and abrasion. It is also an environmentally clean, dry process.

What is Plating (Electroplating)?

Electroplating is a well-established wet chemical process. It uses an electric current to deposit a layer of metal onto a conductive surface.

The Process at a Glance

The part to be coated is submerged in a chemical bath containing dissolved ions of the coating metal. When a direct current is applied, these ions are deposited onto the part, forming a metallic layer.

Key Characteristics

Plating can create relatively thick layers, making it highly effective for corrosion and chemical resistance. It is a mature, cost-effective process renowned for producing bright, classic decorative finishes like chrome, nickel, and gold.

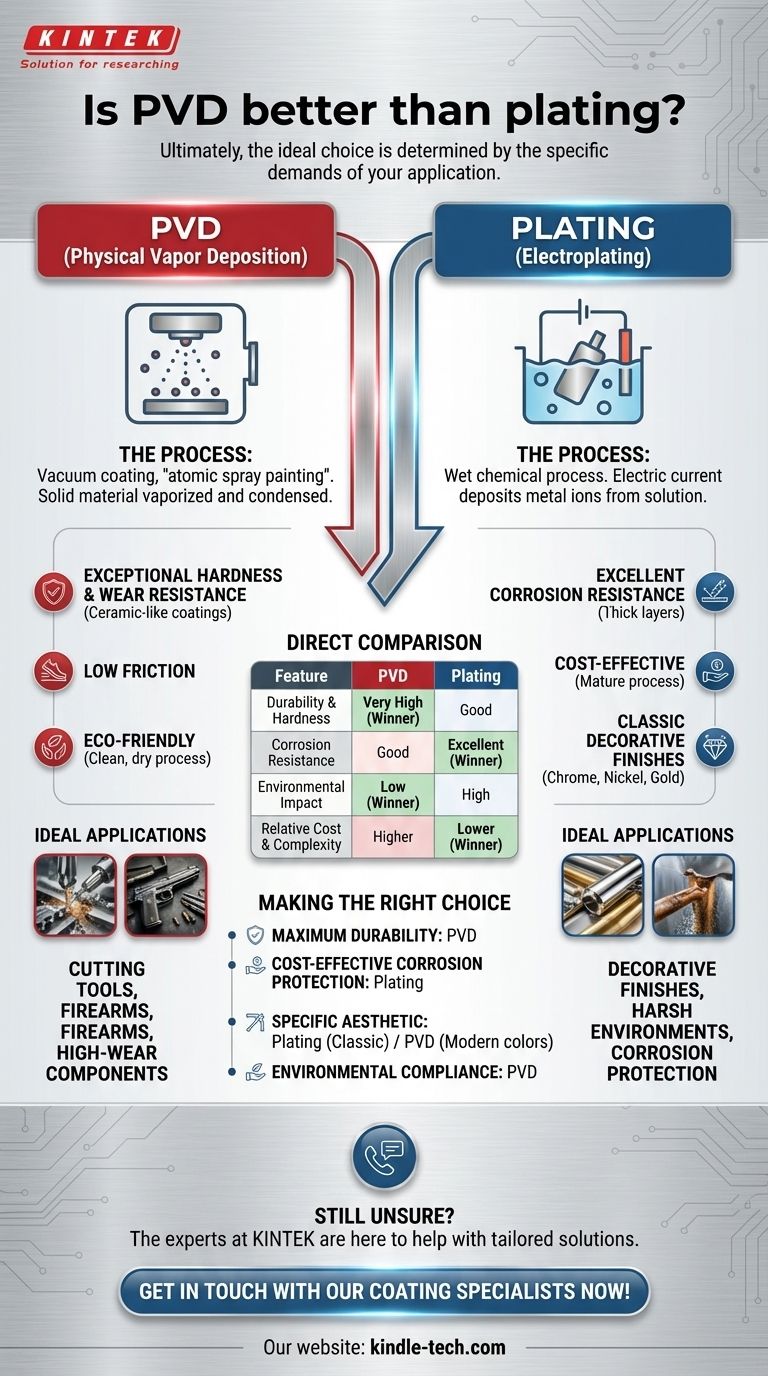

Direct Comparison: PVD vs. Plating

Understanding how these processes stack up across key metrics is crucial for making an informed decision.

Durability and Hardness

PVD is the clear winner for hardness and wear resistance. PVD coatings like Titanium Nitride (TiN) are ceramic in nature and significantly harder than almost any plated metal, making them ideal for cutting tools, firearms, and high-wear components.

Corrosion Resistance

Plating often has the advantage here. Thicker layers of materials like nickel or chromium create a robust barrier against moisture and oxidation. While PVD offers good protection, its very thin nature can be compromised by a deep scratch.

Environmental Impact

PVD is significantly more environmentally friendly. It is a dry process that produces no hazardous byproducts. Electroplating, by contrast, relies on harsh chemical solutions and produces toxic waste that requires careful management and disposal.

Cost and Complexity

Traditional plating is generally less expensive than PVD. The equipment, vacuum chambers, and "complex loading and fixing" required for PVD result in higher capital and operational costs, as noted in process analyses.

Making the Right Choice for Your Application

Your final decision should be guided by the single most important requirement for your product.

- If your primary focus is maximum durability and wear resistance: PVD is the superior choice for applications where hardness and low friction are critical.

- If your primary focus is corrosion resistance at a lower cost: Traditional plating provides excellent, cost-effective protection, especially for parts exposed to harsh environments.

- If your primary focus is a specific aesthetic: Plating excels at classic, bright metallic finishes, while PVD offers a broader palette of modern colors like black, bronze, and gold tones.

- If your primary focus is environmental compliance or biocompatibility: PVD is the definitive choice for its clean process and inert, non-toxic coatings.

By prioritizing your application's most critical need, you can confidently select the coating process that delivers the right performance and value.

Summary Table:

| Feature | PVD (Physical Vapor Deposition) | Plating (Electroplating) |

|---|---|---|

| Primary Strength | Extreme hardness & wear resistance | Cost-effective corrosion resistance |

| Process Type | Dry, vacuum-based physical process | Wet chemical process |

| Durability | Very high (ceramic-like coatings) | Good |

| Corrosion Resistance | Good | Excellent (thicker layers) |

| Environmental Impact | Low (clean, no hazardous waste) | High (toxic waste produced) |

| Relative Cost | Higher | Lower |

| Best For | Cutting tools, high-wear components | Decorative finishes, harsh environments |

Still unsure which coating process is right for your laboratory equipment or components?

The experts at KINTEK are here to help. We specialize in providing tailored solutions for your lab's coating needs, whether you require the extreme durability of PVD or the cost-effective protection of plating.

Contact us today for a personalized consultation, and let us help you enhance the performance and longevity of your equipment.

Get in touch with our coating specialists now!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

- Electric Heated Hydraulic Vacuum Heat Press for Lab

People Also Ask

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- What is the process of CVD diamond coating? Grow a Superior, Chemically-Bonded Diamond Layer