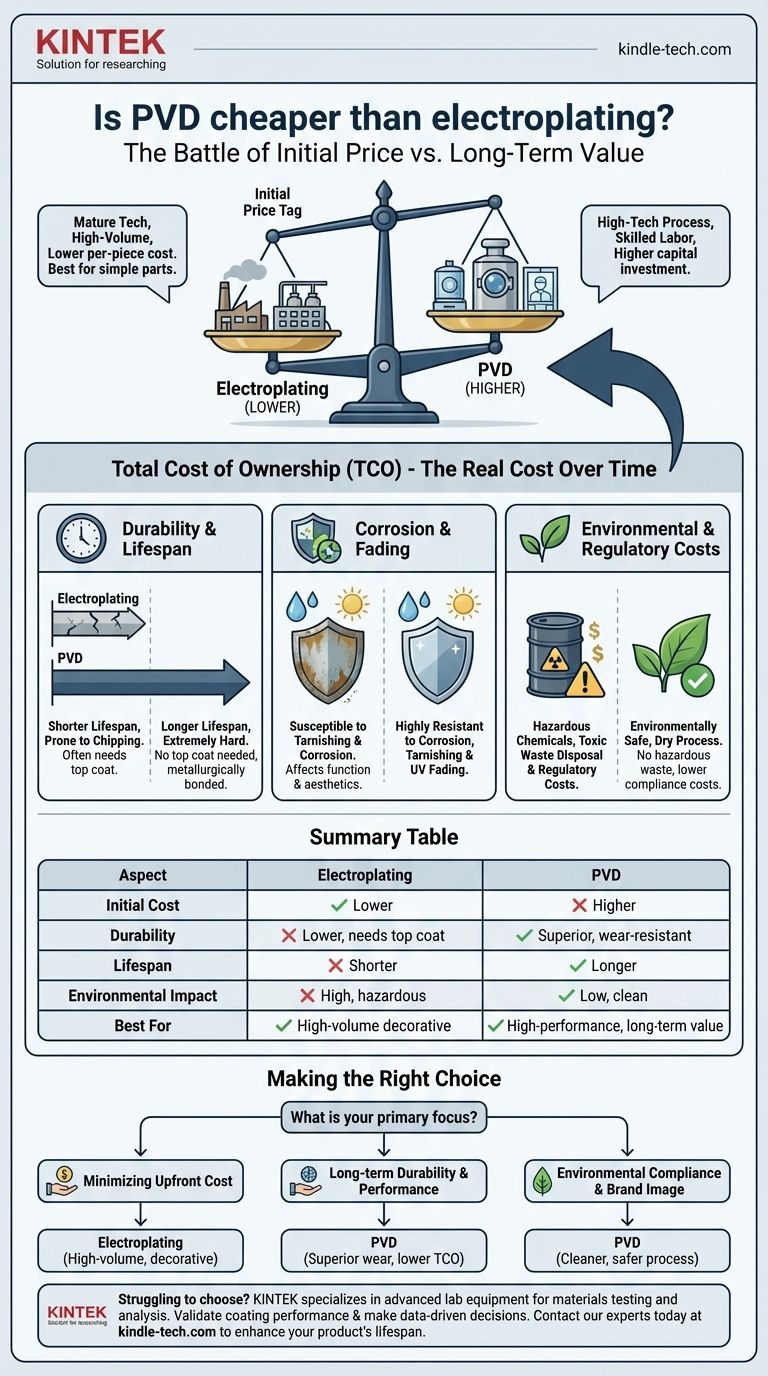

On a per-piece basis, traditional electroplating is often cheaper than Physical Vapor Deposition (PVD) for initial production costs. However, this simple answer overlooks the crucial factor of long-term value. The true cost-effectiveness of a coating is determined not just by its initial price, but by its durability, lifespan, and the indirect costs associated with maintenance and environmental compliance.

The central takeaway is this: while electroplating may win on upfront cost, PVD often provides a lower Total Cost of Ownership (TCO) due to its superior durability, resistance to wear, and environmental safety. The "cheaper" option depends entirely on whether your priority is immediate price or long-term value.

Deconstructing the Upfront Costs

The initial price of any coating process is a function of equipment, materials, and labor. The fundamental differences between electroplating and PVD create a clear cost divergence at the outset.

Why Electroplating Is Often Cheaper Initially

Electroplating is a wet chemical process that has been refined for over a century. The technology is mature, and the equipment for many common plating types (like zinc or nickel) is relatively widespread and less expensive.

This maturity allows for high-throughput, large-batch processing, which drives down the per-piece cost, especially for simple, small components.

The Higher Initial Investment of PVD

PVD is a high-tech vacuum deposition process. It requires a significant capital investment in sophisticated equipment, including a vacuum chamber, high-power sources, and precise process controls.

These systems also demand a highly controlled environment (like a clean room) and more skilled operators, contributing to a higher operational cost and, consequently, a higher initial price per part.

Key Factors Influencing Price

The cost for either process is not static. It is heavily influenced by the part volume, substrate material, the complexity of the part's geometry, and the specific coating material being deposited. PVD, being a line-of-sight process, can be more complex and costly for parts with intricate internal surfaces.

Beyond the Price Tag: Total Cost of Ownership

Focusing only on the initial quote ignores the factors that define a product's success and profitability over its entire lifecycle. This is where PVD demonstrates its true value.

Durability and Product Lifespan

Electroplated finishes, especially for decorative purposes like brass or gold, often require a clear protective top coat. As noted in industry analysis, this clear coat can degrade, chip, or discolor over time.

PVD coatings, by contrast, are metallurgically bonded to the substrate. They are exceptionally hard and do not require a clear top coat, making them significantly more resistant to wear, scratches, and abrasion. A longer-lasting product means fewer warranty claims and replacements, directly reducing long-term costs.

Resistance to Corrosion and Fading

Many electroplated surfaces are susceptible to tarnishing and corrosion, especially when exposed to environmental factors. This degradation compromises both the function and aesthetics of the product.

PVD provides a dense, non-porous barrier that is highly resistant to tarnishing, corrosion, and fading from UV light. This stability reduces maintenance needs and preserves the product's value and appearance for much longer.

Environmental and Regulatory Costs

Traditional electroplating often involves hazardous chemicals, such as cyanide solutions and hexavalent chromium, which is a known carcinogen. Managing, treating, and disposing of this toxic waste is a significant and growing operational cost due to strict environmental regulations.

PVD is an environmentally safe, dry process. It produces no hazardous byproducts, eliminating the costs and risks associated with chemical waste disposal and regulatory compliance.

Understanding the Trade-offs

Neither process is universally superior; the optimal choice is dictated by the specific application's requirements.

When Electroplating Makes Sense

For high-volume, low-cost decorative items that will not be subjected to significant wear or harsh environmental conditions, electroplating can be the most economical choice. Its ability to coat complex shapes uniformly also gives it an advantage for certain parts.

The Limitations of PVD

The primary limitations of PVD are its higher initial cost and its "line-of-sight" nature. Surfaces that are not directly exposed to the coating source in the vacuum chamber will not be coated effectively, making it challenging for parts with deep recesses or complex internal channels. The process also involves heat, which can be a limitation for temperature-sensitive substrate materials.

Making the Right Choice for Your Application

To make an informed decision, you must align the coating's characteristics with your product's primary goal.

- If your primary focus is minimizing upfront manufacturing cost: Electroplating is often the more economical choice, particularly for decorative parts in high-volume production.

- If your primary focus is long-term durability and performance: PVD provides superior wear, abrasion, and corrosion resistance, leading to a lower total cost of ownership and a more reliable product.

- If your primary focus is environmental compliance and brand image: PVD is a significantly cleaner and safer process, aligning with modern corporate responsibility standards and avoiding regulatory burdens.

Ultimately, choosing the right finish requires looking beyond the initial invoice and considering the entire life of your product.

Summary Table:

| Aspect | Electroplating | PVD |

|---|---|---|

| Initial Cost | Lower upfront cost per piece | Higher initial investment |

| Durability | Less durable, may require top coat | Extremely hard, wear-resistant, no top coat needed |

| Lifespan | Shorter, prone to tarnishing/corrosion | Longer, superior corrosion/UV resistance |

| Environmental Impact | Uses hazardous chemicals, high waste disposal costs | Dry, clean process, no hazardous waste |

| Best For | High-volume, low-cost decorative items | High-performance parts requiring long-term value |

Struggling to choose the right coating for durability and value?

KINTEK specializes in advanced lab equipment and consumables for materials testing and analysis. Our expertise can help you validate coating performance and make data-driven decisions for your specific application, ensuring you optimize for both cost and quality.

Contact our experts today to discuss your project needs and discover how KINTEK's solutions can enhance your product's lifespan and performance.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

- Electric Heated Hydraulic Vacuum Heat Press for Lab

People Also Ask

- What is the process of CVD diamond coating? Grow a Superior, Chemically-Bonded Diamond Layer

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability