Yes, PVD coating is exceptionally durable on knives. It is one of the hardest and most wear-resistant finishes available today, created by bonding a thin film of ceramic material to the steel at a molecular level. This process results in a surface that vastly outlasts traditional coatings like paint or chemical bluing in terms of scratch and wear resistance.

The core reason for PVD's durability is that it's not a layer of paint sitting on the surface; it's an extremely hard ceramic film that is atomically bonded to the steel. This provides a finish that is highly resistant to the abrasion and corrosion a knife blade faces during normal use.

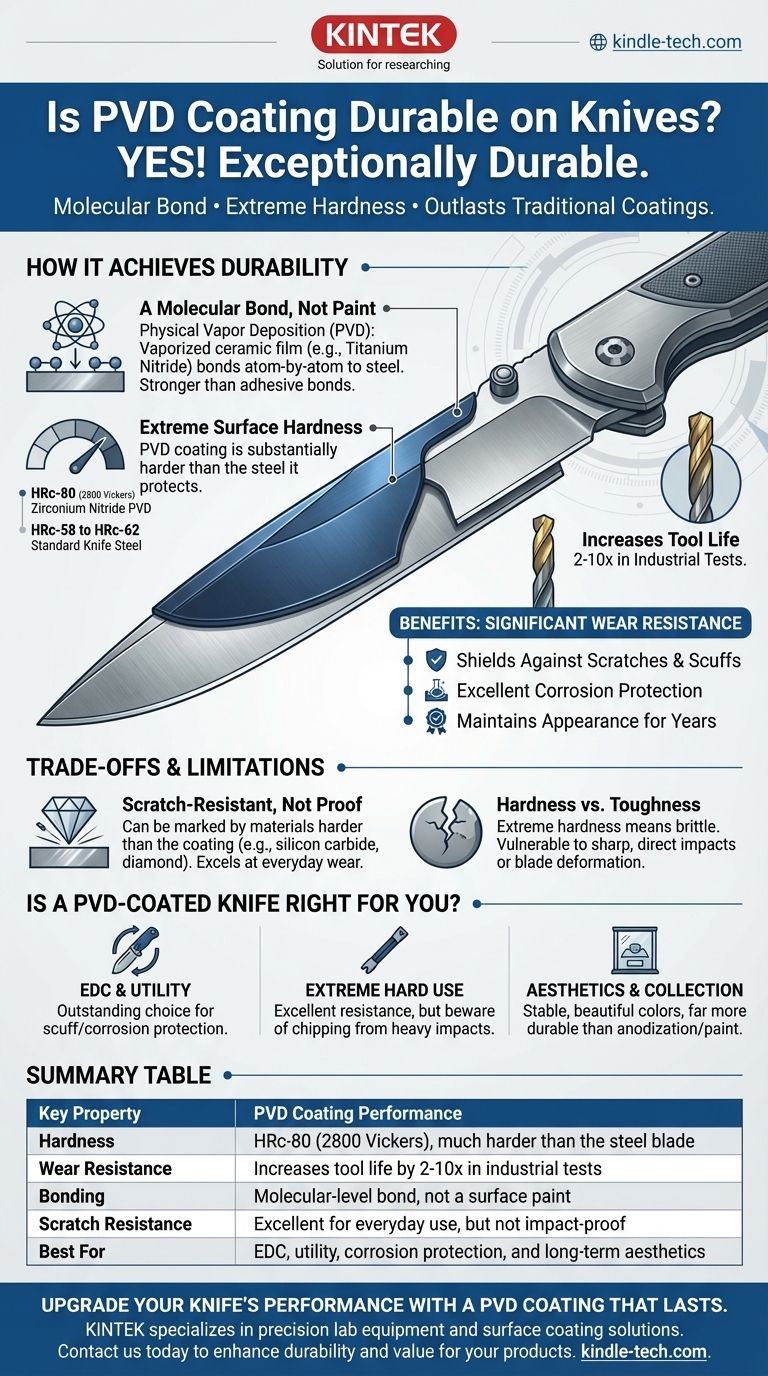

How PVD Achieves Its Durability

A Molecular Bond, Not a Coat of Paint

PVD stands for Physical Vapor Deposition. In this high-tech process, a solid material—often a hard ceramic like titanium nitride—is vaporized in a vacuum chamber.

This vapor then travels and deposits onto the knife blade, atom by atom, creating a dense, thin film that is bonded to the steel's surface. This molecular bond is significantly stronger than the adhesive bond of any paint or polymer.

Extreme Surface Hardness

The materials used for PVD coatings are incredibly hard. For example, Zirconium Nitride (ZrN), used for some brass-colored PVD finishes, can have a hardness of around HRc-80 (2800 Vickers).

To put that in perspective, a well-hardened knife blade steel is typically in the HRc-58 to HRc-62 range. The PVD coating is substantially harder than the steel it protects.

Significant Increase in Wear Resistance

This hardness translates directly to performance. In industrial applications, PVD coatings can increase the life of cutting tools by 2 to 10 times.

While a knife blade doesn't face the exact same stresses as an industrial drill bit, the principle is the same. The PVD coating acts as a protective shield, absorbing the scratches and scuffs that would otherwise damage the steel.

Understanding the Trade-offs and Limitations

It is Scratch-Resistant, Not Scratch-Proof

While PVD is incredibly hard, it is not invincible. A material that is harder than the coating can still scratch it.

Abrasives containing silicon carbide or diamond, or even the edge of a ceramic plate, can potentially mark a PVD finish. It excels at resisting everyday wear from cutting cardboard, rope, or interacting with pocket items.

Hardness vs. Toughness

The extreme hardness of the ceramic PVD coating also means it is brittle. It resists abrasive wear exceptionally well, but a sharp, direct impact against a hard object (like another piece of steel or a rock) can cause it to chip.

The coating is only as strong as the steel beneath it. If the blade itself is dented or deformed from a major impact, the PVD coating will fail at that point.

Is a PVD-Coated Knife Right for You?

Choosing a PVD-coated knife depends entirely on your intended use and priorities.

- If your primary focus is everyday carry and utility: A PVD coating is an outstanding choice that will protect your blade from scuffs, minor scratches, and corrosion far better than uncoated steel or traditional finishes.

- If your primary focus is extreme hard use (e.g., batoning, prying): The coating will still provide excellent corrosion and abrasion resistance, but be aware that it can chip from heavy impacts, just as any finish would.

- If your primary focus is aesthetics and collection: PVD offers a range of stable, beautiful colors that are far more durable than anodization or paint, ensuring the knife maintains its appearance for years.

Ultimately, a PVD coating is a premium feature that adds significant functional durability and wear resistance to a knife blade.

Summary Table:

| Key Property | PVD Coating Performance |

|---|---|

| Hardness | HRc-80 (2800 Vickers), much harder than the steel blade |

| Wear Resistance | Increases tool life by 2-10x in industrial tests |

| Bonding | Molecular-level bond, not a surface paint |

| Scratch Resistance | Excellent for everyday use, but not impact-proof |

| Best For | EDC, utility, corrosion protection, and long-term aesthetics |

Upgrade your knife's performance with a PVD coating that lasts. At KINTEK, we specialize in precision lab equipment and surface coating solutions. Whether you're a manufacturer looking to enhance blade durability or a researcher testing material hardness, our expertise ensures superior results. Contact us today to learn how our PVD coatings can add value to your products and meet your specific laboratory needs.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Touchscreen Automatic Vacuum Heat Press

- Lab Blown Film Extrusion Three Layer Co-Extrusion Film Blowing Machine

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

People Also Ask

- What does PVD sputtering mean? A Guide to High-Performance Thin Film Deposition

- What is magnetron sputtering machine? Precision Thin-Film Deposition for Advanced Materials

- How many types of vapor phase deposition techniques are present? PVD vs. CVD Explained

- Is sputtering a PVD? Discover the Key Coating Technology for Your Lab

- What is a sputtering system? Achieve Unmatched Thin Film Deposition for Your Lab