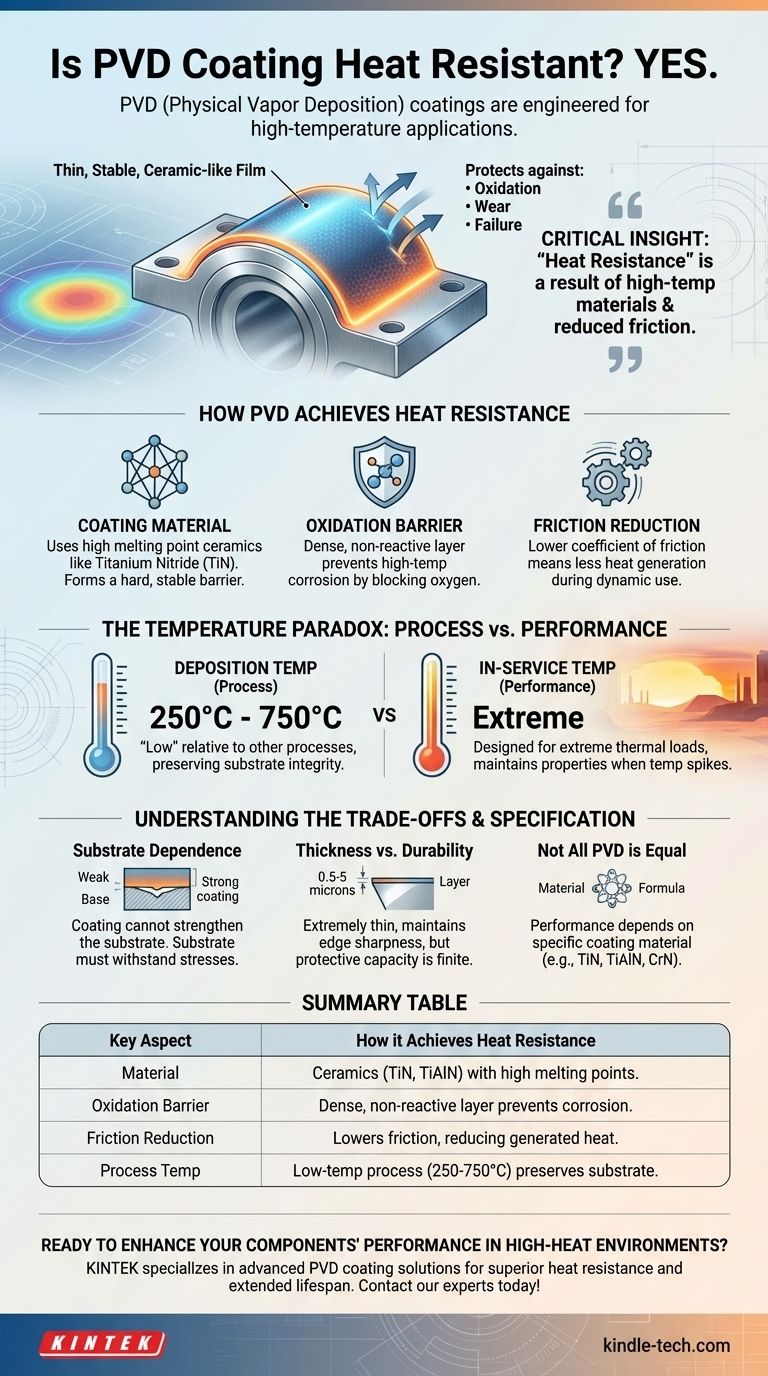

In short, yes. Physical Vapor Deposition (PVD) coatings are engineered to be highly resistant to heat and are frequently used in high-temperature applications. The process creates a thin, ceramic-like film on a molecular level that is not only hard but also exceptionally stable, allowing it to protect the underlying material from oxidation, wear, and failure in high-heat environments like industrial cutting.

The critical insight is that PVD's "heat resistance" is not a single property. It is the result of using specific, high-temperature materials and a process that reduces friction, which in turn lowers the heat generated during use.

How PVD Achieves Heat Resistance

The thermal performance of a PVD-coated part comes from a combination of the coating material's intrinsic properties and its effect on the entire component system.

The Role of Coating Material

PVD is a process, not a single material. The heat resistance of the final product is primarily determined by the material being deposited, often a ceramic like Titanium Nitride (TiN).

These materials are chosen for their high melting points, chemical stability, and hardness at elevated temperatures, forming a protective barrier that shields the substrate.

Preventing High-Temperature Oxidation

At high temperatures, most metals react with oxygen in the air, leading to oxidation (corrosion) and degradation.

PVD coatings are exceptionally dense and non-reactive. They create a stable barrier that prevents oxygen from reaching the substrate material, dramatically slowing down this high-temperature corrosion.

Reducing Frictional Heat Generation

In dynamic applications like cutting tools or engine components, a significant amount of heat is generated by friction.

PVD coatings significantly reduce the coefficient of friction. This "lubricity" means less heat is created in the first place, allowing the tool or part to run cooler and last longer under thermal stress.

The Temperature Paradox: Process vs. Performance

It can be confusing to hear that PVD is a "low-temperature" process while also being highly "heat-resistant." This distinction is crucial to understand.

Deposition Temperature (250°C - 750°C)

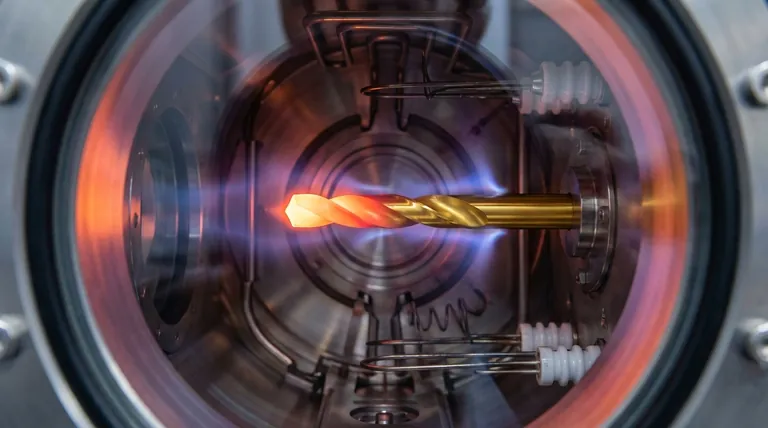

The PVD process itself is performed in a vacuum chamber at elevated temperatures, typically between 250°C and 750°C. This is required to vaporize the coating material and ensure it forms a strong, dense bond with the part's surface.

Why This is a "Low Temperature" Process

This temperature range is considered low relative to other coating processes like Chemical Vapor Deposition (CVD), which can exceed 1000°C.

PVD's lower processing temperature is a major advantage because it stays below the transformation temperature of many steels and alloys. This means it can be applied to finished, heat-treated parts without softening them or altering their fundamental structural integrity.

In-Service Temperature Resistance

The finished PVD coating is designed to perform reliably in applications involving extreme thermal loads. Its resistance to "high-temperature cutting" and "evaporation" means it maintains its protective properties even when the surface temperature spikes during use.

Understanding the Trade-offs

While powerful, PVD is a surface treatment with specific limitations that are critical to consider for any successful application.

Dependence on the Substrate

A PVD coating cannot make an underlying material stronger than it is. The coating protects the surface, but the bulk of the part must still be able to withstand the mechanical and thermal stresses of the application.

If the substrate material softens, deforms, or melts under heat, the coating will fail along with it.

Coating Thickness vs. Durability

PVD coatings are extremely thin, typically between 0.5 and 5 microns. This is an advantage for maintaining the sharpness of cutting edges but also means their protective capacity is finite.

They are designed to resist wear and oxidation, but they are not a replacement for using a substrate material appropriate for the operating environment.

Not All PVD is Created Equal

The term "PVD" is general. The actual performance depends entirely on the specific coating material used (e.g., TiN, TiAlN, CrN). Each has a different combination of hardness, lubricity, and maximum operating temperature.

How to Specify PVD for Your Goal

To leverage PVD effectively, you must match the coating to the primary challenge you are trying to solve.

- If your primary focus is high-wear, high-heat applications (e.g., cutting tools): Specify a coating known for hot hardness, such as Titanium Aluminum Nitride (TiAlN), which is designed to perform under extreme thermal cycling.

- If your primary focus is corrosion resistance at moderate temperatures (e.g., architectural hardware): A coating like Titanium Nitride (TiN) or Chromium Nitride (CrN) provides excellent oxidation resistance and durability without the cost of a more specialized high-temp formula.

- If your primary focus is coating a heat-sensitive part: The key benefit of PVD is its lower deposition temperature, which protects the substrate from thermal damage during the coating process itself.

Ultimately, successful implementation of PVD relies on understanding it as a surface engineering solution, where the coating, substrate, and application must all work in harmony.

Summary Table:

| Key Aspect | How PVD Coating Achieves Heat Resistance |

|---|---|

| Material | Uses ceramics like TiN & TiAlN with high melting points and thermal stability. |

| Oxidation Barrier | Creates a dense, non-reactive layer to prevent high-temperature corrosion. |

| Friction Reduction | Lowers the coefficient of friction, reducing heat generation during use. |

| Process Temperature | Applied at 250°C - 750°C, a 'low-temperature' process that preserves substrate integrity. |

Ready to enhance your components' performance in high-heat environments? KINTEK specializes in advanced PVD coating solutions for laboratory equipment and industrial tools. Our expertise ensures your parts gain superior heat resistance, reduced wear, and extended lifespan. Contact our experts today to discuss how our PVD coatings can solve your specific thermal challenges!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

People Also Ask

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools

- What is the process of CVD diamond coating? Grow a Superior, Chemically-Bonded Diamond Layer

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application