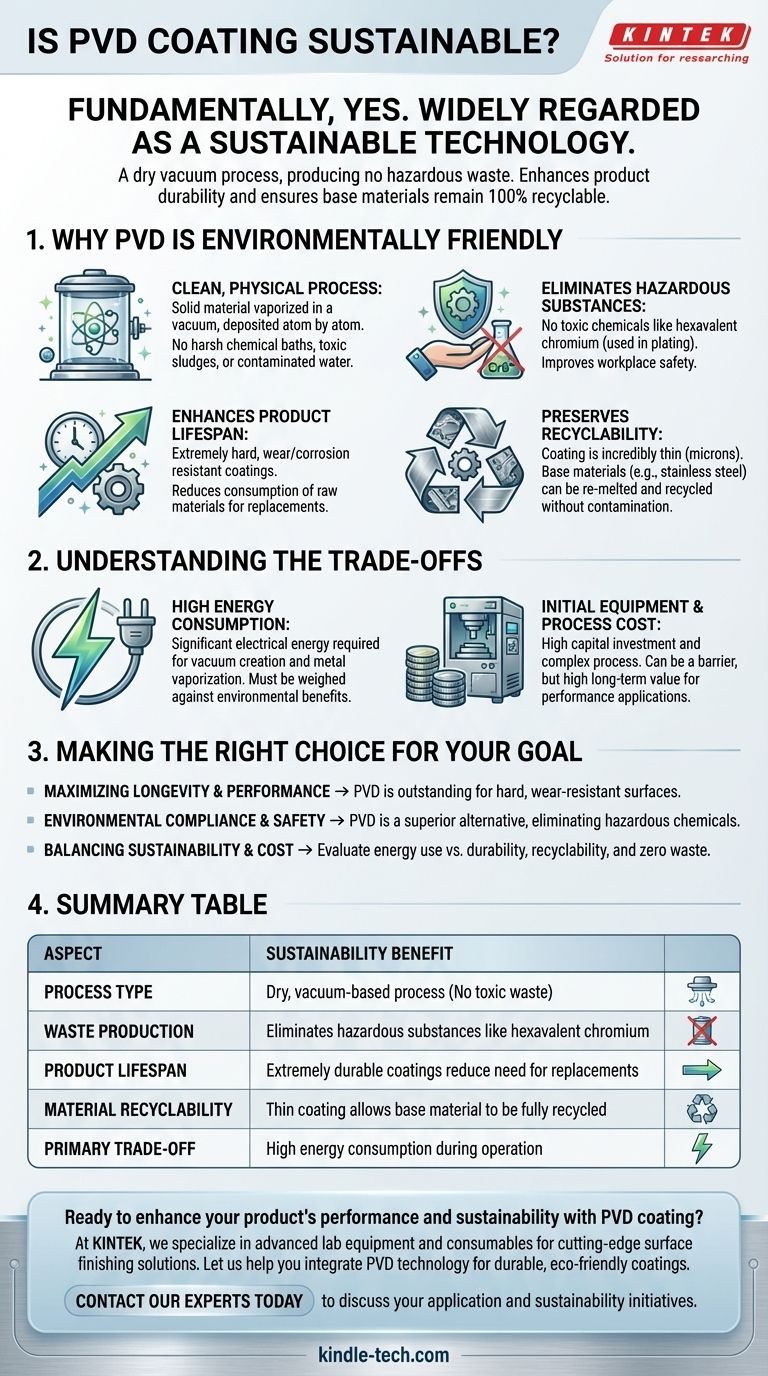

Fundamentally, yes, Physical Vapor Deposition (PVD) is widely regarded as a sustainable coating technology. Unlike traditional coating methods that rely on wet chemical processes, PVD is a dry vacuum process that produces no hazardous waste. It enhances product durability and allows the base materials, such as stainless steel, to remain 100% recyclable.

The sustainability of PVD is not just about its clean production process; it's about its entire lifecycle benefit. By creating an extremely durable, long-lasting surface, PVD extends product life, reduces the need for replacements, and avoids the toxic byproducts inherent in older coating techniques.

Why PVD is Considered an Environmentally Friendly Process

Physical Vapor Deposition is a group of processes where a solid material is vaporized in a vacuum and condensed onto a substrate's surface to form a very thin, dense coating. This fundamental mechanism is the source of its environmental advantages.

It's a Clean, Physical Process

PVD is defined by its physics, not its chemistry. A solid source material—often a metal or ceramic—is vaporized using heat or plasma inside a vacuum chamber.

These vaporized atoms then travel through the vacuum and deposit onto the component, forming the coating atom by atom. Because this happens in a controlled vacuum, there are no harsh chemical baths, toxic sludges, or contaminated water to dispose of.

It Eliminates Hazardous Substances

Traditional plating methods, such as chrome plating, often involve baths of hazardous chemicals like hexavalent chromium, a known carcinogen.

PVD completely sidesteps this issue. The process is entirely self-contained, using only the target material and electricity, which drastically improves workplace safety and eliminates environmental contamination from waste disposal.

It Enhances Product Lifespan

A core tenet of sustainability is creating products that last longer. PVD coatings are exceptionally hard and provide superior resistance to wear, corrosion, and scratches.

By protecting the underlying material, a PVD coating can dramatically extend the functional life of a component. This reduces the consumption of raw materials and energy that would otherwise be needed to manufacture replacements.

It Preserves Recyclability

A common concern with coatings is their impact on the recyclability of the base material. The PVD coating is incredibly thin—often just a few microns.

This means that at the end of a product's life, PVD-coated materials like stainless steel can be re-melted and recycled without issue. The coating is so minimal that it does not contaminate the recycling stream.

Understanding the Trade-offs

No technology is without its compromises. Acknowledging the trade-offs is crucial for making an informed decision.

High Energy Consumption

Creating a high vacuum and vaporizing solid metals requires a significant amount of electrical energy. This is the primary environmental cost associated with the PVD process.

The energy demand must be weighed against the environmental benefits, such as extended product life and the elimination of toxic waste from alternative processes.

Initial Equipment and Process Cost

PVD systems represent a significant capital investment. The process is also more complex than simple painting or dipping, requiring skilled operators.

While not a direct environmental factor, this cost can be a barrier to adoption, particularly for smaller-scale operations. However, for high-performance applications, the long-term value often justifies the initial expense.

Making the Right Choice for Your Goal

PVD is a powerful tool, but its suitability depends on your project's specific priorities.

- If your primary focus is maximizing product longevity and performance: PVD is an outstanding choice for creating a hard, wear-resistant surface that extends the life of critical components.

- If your primary focus is environmental compliance and safety: PVD is a superior alternative to traditional electroplating, as it eliminates the use and disposal of hazardous chemical solutions.

- If your primary focus is balancing sustainability and cost: You must evaluate PVD's high energy consumption and initial cost against the total lifecycle benefits of durability, recyclability, and zero hazardous waste.

By understanding its full lifecycle impact, you can confidently specify PVD as a modern, responsible, and high-performance finishing solution.

Summary Table:

| Aspect | Sustainability Benefit |

|---|---|

| Process Type | Dry, vacuum-based process (no toxic chemical waste) |

| Waste Production | Eliminates hazardous substances like hexavalent chromium |

| Product Lifespan | Extremely durable coatings reduce need for replacements |

| Material Recyclability | Thin coating allows base material (e.g., steel) to be fully recycled |

| Primary Trade-off | High energy consumption during operation |

Ready to enhance your product's performance and sustainability with PVD coating?

At KINTEK, we specialize in providing advanced lab equipment and consumables for cutting-edge surface finishing solutions. Our expertise can help you integrate PVD technology to achieve durable, eco-friendly coatings that meet your performance goals while adhering to strict environmental standards.

Contact our experts today to discuss how PVD coating can benefit your specific application and contribute to your sustainability initiatives.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is PECVD used for? Achieve Low-Temperature, High-Performance Thin Films

- What is plasma enhanced chemical vapor deposition? Achieve Low-Temperature, High-Quality Thin Films

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- What is the difference between CVD and PECVD? Choose the Right Thin-Film Deposition Method

- What is plasma in CVD process? Lowering Deposition Temperatures for Heat-Sensitive Materials