In practice, yes, a PVD coating itself is effectively waterproof. The Physical Vapor Deposition process creates an extremely dense, non-porous film that is molecularly bonded to the surface. This layer forms a stable barrier that prevents water and other molecules from penetrating through to the underlying material, making it highly resistant to corrosion, oxidation, and tarnish.

The core function of a PVD coating is not to make an object waterproof, but to make its surface incredibly durable and resistant to corrosion. While the PVD film itself is a waterproof barrier, the true benefit lies in how it protects the underlying material from the damaging effects of moisture and wear.

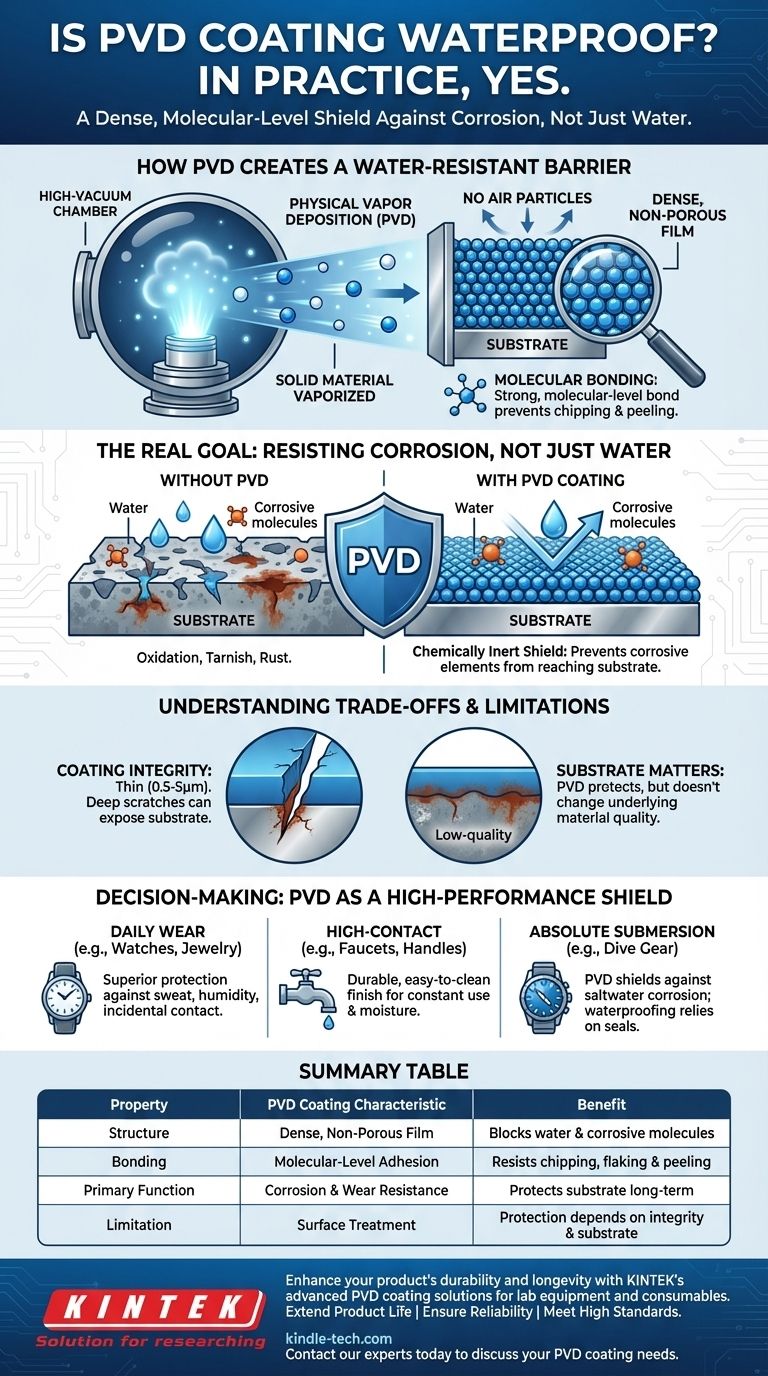

How PVD Creates a Water-Resistant Barrier

Physical Vapor Deposition is a process performed in a high-vacuum environment where a solid material is vaporized, and its atoms are deposited one by one onto a substrate. This meticulous layering process is key to its protective qualities.

The Role of Molecular Bonding

PVD is not like paint, which simply sits on a surface. The deposited material forms a strong, molecular-level bond with the substrate. This exceptional adhesion means the coating won't easily chip, flake, or peel away, ensuring the protective barrier remains intact.

A Dense, Non-Porous Film

Because the process occurs in a vacuum, there are no air particles or contaminants to create imperfections. The atoms condense into a solid, uniform film that is virtually free of pores or gaps. It is this dense structure that blocks water molecules from passing through.

The Real Goal: Resisting Corrosion, Not Just Water

When you ask if something is "waterproof," you are often really asking if it will be damaged by water. PVD's primary purpose is to prevent this very damage on a long-term basis.

Preventing Oxidation and Tarnish

Water, especially when combined with salt from sweat or chemicals in the air, accelerates corrosion (like rust) and tarnish. A PVD coating is chemically inert and highly stable, acting as a shield that prevents these corrosive elements from ever reaching the metal underneath.

Enhancing the Substrate

PVD is typically applied to materials like stainless steel or titanium that already have good corrosion resistance. The coating elevates this property to a much higher level, ensuring the product's finish and structural integrity are preserved even with frequent exposure to moisture.

Understanding the Trade-offs and Limitations

While extremely effective, it's important to understand the context of PVD's protection. It is a surface treatment, not an intrinsic property of the object.

A Coating Is Only as Good as Its Integrity

PVD coatings are exceptionally hard and wear-resistant, but they are also very thin (typically 0.5 to 5 microns). A deep scratch or gouge that fully penetrates the coating can expose the underlying substrate. If the substrate is susceptible to rust, corrosion can begin at that point of damage.

The Substrate Still Matters

The overall durability of the product is a combination of the PVD coating and the base material. If a coating on a low-quality, rust-prone metal is compromised, rust can potentially begin to creep under the edges of the intact film over time. The PVD coating protects the surface, but it doesn't change the fundamental nature of the material it covers.

How to Apply This to Your Decision

Consider the PVD coating as a high-performance protective shield rather than a simple waterproofing seal. Its value is in preserving the look and life of the product against environmental exposure.

- If your primary focus is daily-wear items like watches or jewelry: PVD is an excellent choice, offering superior protection against sweat, humidity, and incidental water contact that would otherwise cause tarnish or wear.

- If your primary focus is high-contact fixtures like faucets or door handles: The hardness and corrosion resistance of PVD provide a durable, long-lasting finish that is easy to clean and withstands constant use and moisture.

- If your primary focus is absolute waterproofing for submersion: The waterproofing of an object like a dive watch depends on its gaskets, seals, and case construction; the PVD coating's role here is to provide an external shield against corrosion from saltwater.

Ultimately, you can trust a PVD-coated surface to be impervious to water, protecting the material beneath it from corrosion and preserving its intended finish.

Summary Table:

| Property | PVD Coating Characteristic | Benefit |

|---|---|---|

| Structure | Dense, Non-Porous Film | Blocks water and corrosive molecules |

| Bonding | Molecular-Level Adhesion | Resists chipping, flaking, and peeling |

| Primary Function | Corrosion & Wear Resistance | Protects the underlying substrate long-term |

| Limitation | Surface Treatment | Protection depends on coating integrity and substrate quality |

Enhance your product's durability and longevity with KINTEK's advanced PVD coating solutions.

Specializing in lab equipment and consumables, we understand the critical need for reliable, corrosion-resistant surfaces. Our PVD coatings provide a superior protective barrier that safeguards your instruments and components against moisture, chemicals, and daily wear.

Partner with KINTEK to:

- Extend Product Life: Protect valuable equipment from corrosion and tarnish.

- Ensure Reliability: Benefit from a durable, non-porous finish that maintains integrity.

- Meet High Standards: Achieve consistent, high-quality results for your laboratory needs.

Contact our experts today to discuss how our PVD coating services can protect your laboratory investments.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings