Yes, PVD coatings are highly corrosion-resistant. This is one of their primary engineering advantages. The Physical Vapor Deposition (PVD) process creates a dense, durable film at an atomic level that serves as a powerful barrier against rust and other forms of corrosion, often outperforming traditional finishes like electroplating in standardized tests.

The exceptional corrosion resistance of PVD is not an accident; it is a direct result of the deposition process itself, which builds a highly-controlled, non-porous shield that is molecularly bonded to the surface it protects.

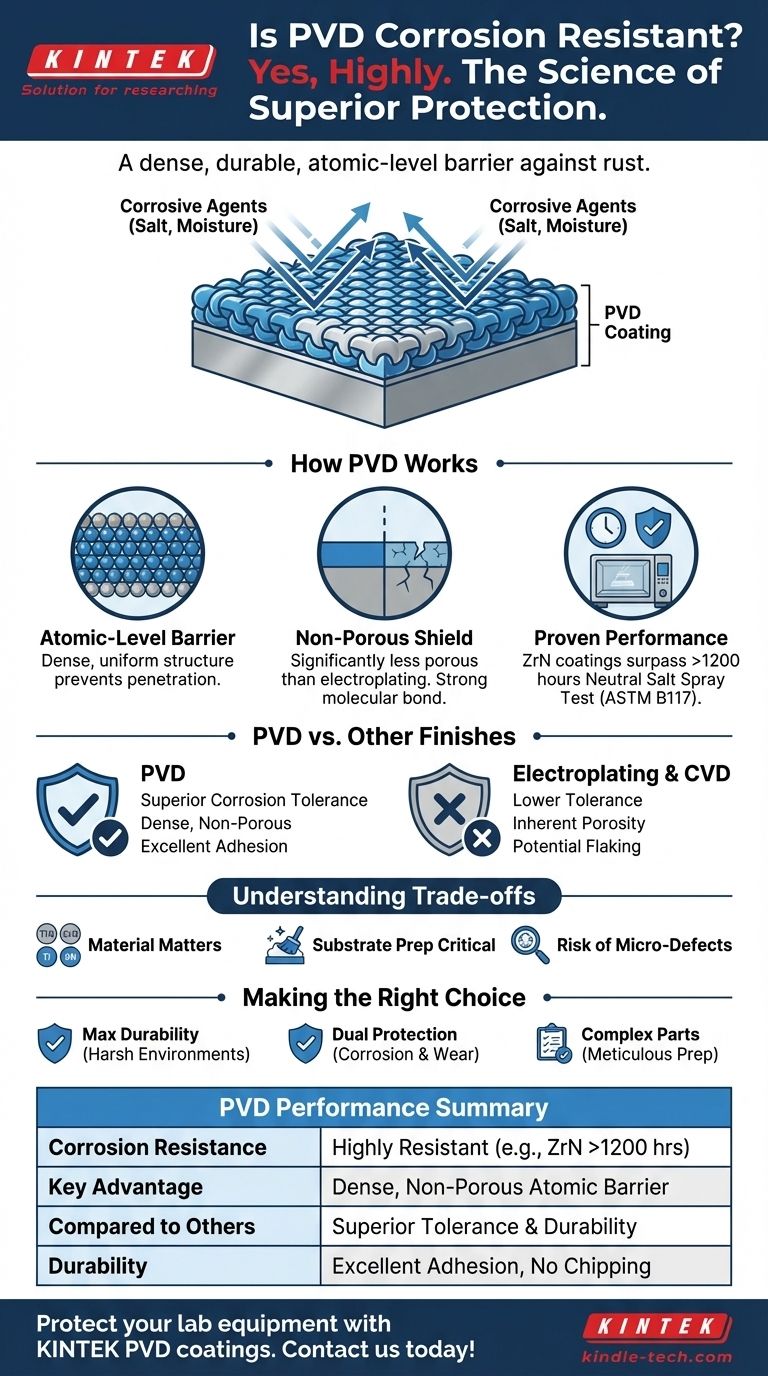

How PVD Achieves Superior Corrosion Resistance

The effectiveness of PVD comes from the fundamental way the coating is applied. It is not simply a layer of paint; it is an integrated part of the surface.

The Atomic-Level Barrier

PVD applies coatings at the atomic level in a vacuum. This allows for precise control over the film's structure, density, and uniformity.

This process creates a very dense layer with minimal defects, leaving no pathways for corrosive agents like salt or moisture to penetrate and attack the underlying material.

A Non-Porous Shield

Compared to methods like electroplating, which can have inherent porosity, PVD films are significantly less porous. This is a critical factor in preventing the start of corrosion.

The molecular bond created by PVD also ensures excellent adhesion, preventing the coating from chipping or flaking, which would otherwise expose the substrate to the elements.

Proven Performance in Harsh Conditions

The resistance of PVD coatings is quantifiable. Specific coatings like Zirconium Nitride (ZrN) have been shown to surpass 1200 hours of neutral salt spray testing (ASTM B117).

This level of performance meets or exceeds the requirements for most industrial and commercial applications, confirming its reliability in real-world conditions.

PVD Compared to Other Finishes

A key part of understanding PVD's value is seeing how it stacks up against other common surface treatments.

PVD vs. Electroplating

PVD coatings demonstrate a higher corrosion tolerance than most electroplated finishes. The dense, non-porous nature of the PVD layer provides a more robust and long-lasting barrier.

PVD vs. CVD

While both are deposition techniques, PVD coatings generally exhibit better corrosion resistance than those applied via Chemical Vapor Deposition (CVD).

Understanding the Trade-offs and Limitations

While highly effective, no solution is perfect. Objectivity requires acknowledging the context in which PVD operates best.

Not All PVD is Created Equal

The term "PVD" describes a process, not a single material. The specific material used—such as Titanium Nitride (TiN) or Zirconium Nitride (ZrN)—determines the final properties, including the exact level of corrosion resistance.

Substrate Preparation is Critical

The performance of any PVD coating is highly dependent on the quality and preparation of the underlying material (the substrate). An improperly prepared surface can compromise adhesion and create weak points.

Risk of Microscopic Defects

Although the process minimizes defects, microscopic pinholes can still occur. In extremely aggressive chemical environments, these could theoretically become points of localized corrosion over very long periods.

Making the Right Choice for Your Application

Selecting the right finish depends entirely on your project's specific goals and environmental challenges.

- If your primary focus is maximum durability in harsh environments: PVD is an excellent choice, proven to outperform traditional plating in standardized salt-spray corrosion tests.

- If you need to protect against both corrosion and wear: The inherent hardness and lubricity of many PVD coatings make them a superior dual-purpose solution.

- If you are coating a complex part: Ensure your process includes meticulous surface preparation, as the integrity of the PVD barrier depends on perfect adhesion to the substrate.

Ultimately, choosing PVD is a decision for superior, engineered protection against the gradual failure caused by corrosion.

Summary Table:

| Aspect | PVD Performance |

|---|---|

| Corrosion Resistance | Highly resistant; proven in salt spray tests (e.g., ZrN >1200 hours ASTM B117) |

| Key Advantage | Dense, non-porous atomic-level barrier prevents moisture and salt penetration |

| Compared to Electroplating | Superior corrosion tolerance and durability |

| Durability | Excellent adhesion prevents chipping/flaking, ensuring long-term protection |

Protect your laboratory equipment and components with the superior corrosion resistance of PVD coatings. KINTEK specializes in high-performance lab equipment and consumables. Our expertise ensures your materials are shielded from harsh environments, enhancing their lifespan and reliability. Contact us today to find the perfect PVD solution for your laboratory's needs!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Electrolytic Electrochemical Cell for Coating Evaluation

- Isostatic Molding Pressing Molds for Lab

People Also Ask

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools

- Is diamond coating worth it? Maximize Component Life and Performance

- What is the process of CVD diamond coating? Grow a Superior, Chemically-Bonded Diamond Layer

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose