Yes, PVD is an exceptionally long-lasting coating. Physical Vapor Deposition (PVD) creates a surface finish that is molecularly bonded to the base material, resulting in a super-hard layer that is far more durable than traditional plating or painting methods. Its inherent properties make it highly resistant to scratches, abrasion, and tarnishing.

The crucial takeaway is that PVD is not simply a layer of paint; it's a sophisticated process that integrates a thin film of durable material directly into the surface of an object, fundamentally enhancing its hardness and resistance to wear.

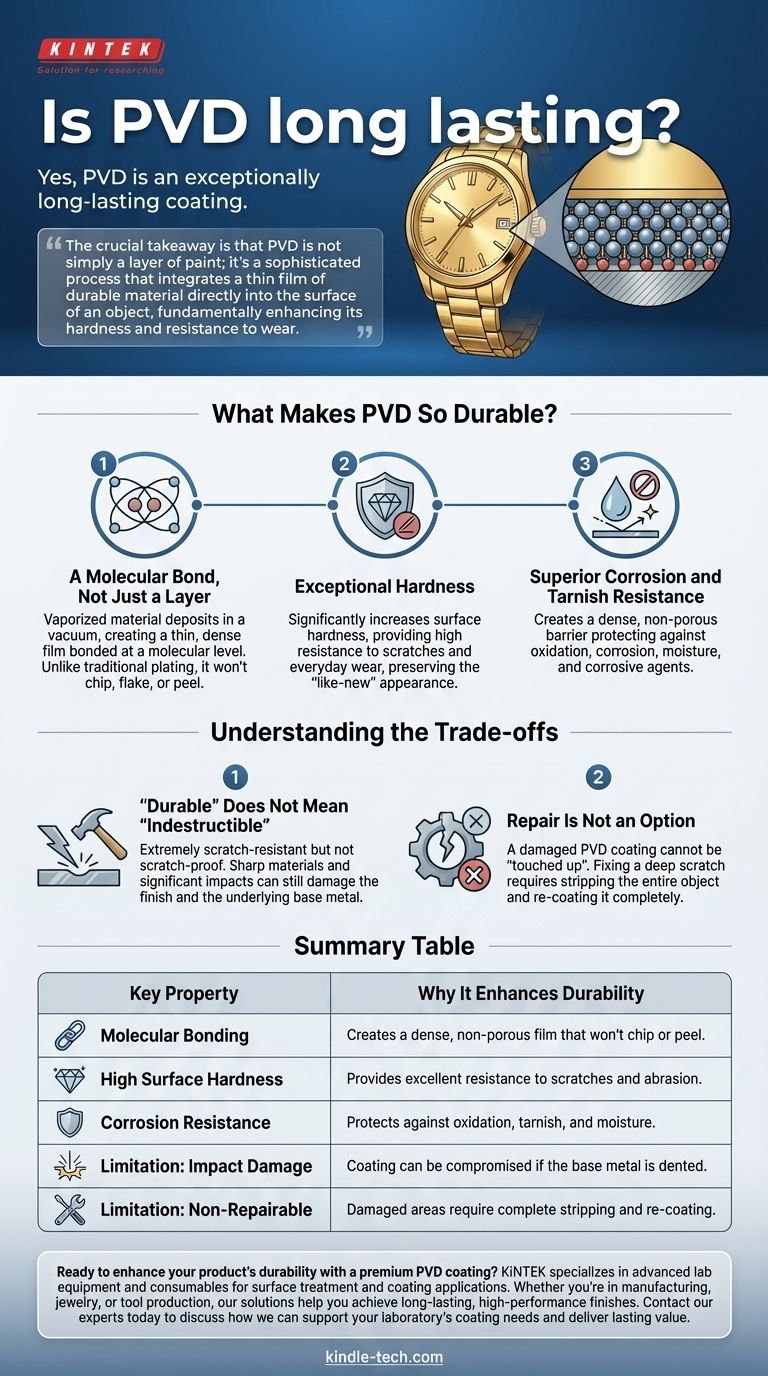

What Makes PVD So Durable?

The longevity of a PVD coating comes from the unique way it's applied and the properties it imparts to the surface. It's a process designed from the ground up for resilience.

A Molecular Bond, Not Just a Layer

The PVD process takes place in a vacuum and involves vaporizing a solid material into plasma. These atoms or molecules are then deposited onto the target object, creating a thin, dense film that is bonded at a molecular level.

This is fundamentally different from traditional plating, which simply lays a new material on top. The PVD bond ensures the coating won't chip, flake, or peel away under normal use.

Exceptional Hardness

PVD coatings significantly increase the surface hardness of the object. This is a primary reason for its high resistance to scratches and everyday wear and tear.

For items like watches, faucets, or tools that are handled frequently, this added hardness is what preserves the "like-new" appearance for years.

Superior Corrosion and Tarnish Resistance

The process creates a dense, non-porous barrier that protects the base metal from the elements. This gives PVD-coated items excellent resistance to oxidation, corrosion, and tarnishing.

This is why it is a preferred finish for jewelry and bathroom fixtures, which are often exposed to moisture, sweat, and other corrosive agents.

Understanding the Trade-offs

While PVD is a superior coating, it is essential to understand its limitations. No finish is truly indestructible.

"Durable" Does Not Mean "Indestructible"

A PVD coating is extremely scratch-resistant, but it is not scratch-proof. A sufficiently hard or sharp material can still damage the finish.

Furthermore, PVD provides surface hardness but does not protect the object from dents. A significant impact can still damage the underlying base metal, which may compromise the coating in that area.

The Coating Is Only as Good as the Base

The overall durability is also dependent on the substrate material. Applying a PVD coating to a very soft metal will protect it from scratches, but the object itself can still be easily dented, which could damage the bonded finish.

Repair Is Not an Option

One of the most significant trade-offs is that a damaged PVD coating cannot be "touched up" or repaired. Because the coating is applied in a specialized vacuum chamber, the only way to fix a deep scratch or worn area is to strip the entire object and re-coat it completely.

Making the Right Choice for Your Goal

PVD offers a clear advantage in longevity for most applications, but understanding its profile helps you align it with your needs.

- If your primary focus is daily wear and tear: Choose PVD for items like watches, jewelry, or high-touch fixtures, as its resistance to scratches and tarnish is unmatched by other coatings.

- If your primary focus is protecting against heavy impacts: Recognize that while PVD adds incredible surface durability, it does not make the underlying object immune to dents or gouges.

Ultimately, PVD is the definitive choice for a premium, long-lasting finish that maintains its appearance through years of consistent use.

Summary Table:

| Key Property | Why It Enhances Durability |

|---|---|

| Molecular Bonding | Creates a dense, non-porous film that won't chip or peel. |

| High Surface Hardness | Provides excellent resistance to scratches and abrasion. |

| Corrosion Resistance | Protects against oxidation, tarnish, and moisture. |

| Limitation: Impact Damage | Coating can be compromised if the base metal is dented. |

| Limitation: Non-Repairable | Damaged areas require complete stripping and re-coating. |

Ready to enhance your product's durability with a premium PVD coating? KINTEK specializes in advanced lab equipment and consumables for surface treatment and coating applications. Whether you're in manufacturing, jewelry, or tool production, our solutions help you achieve long-lasting, high-performance finishes. Contact our experts today to discuss how we can support your laboratory's coating needs and deliver lasting value.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance