Yes, pyrolysis oil is hazardous. It is a corrosive substance that poses significant long-term health risks, as exposure can cause genetic defects and cancer. Its chemical instability creates additional handling and storage challenges that distinguish it from conventional petroleum products.

The core issue is that pyrolysis oil is not a stable, finished product. It is a reactive intermediate mixture of partially decomposed biomass, and this inherent instability is the root cause of its significant health, chemical, and physical hazards.

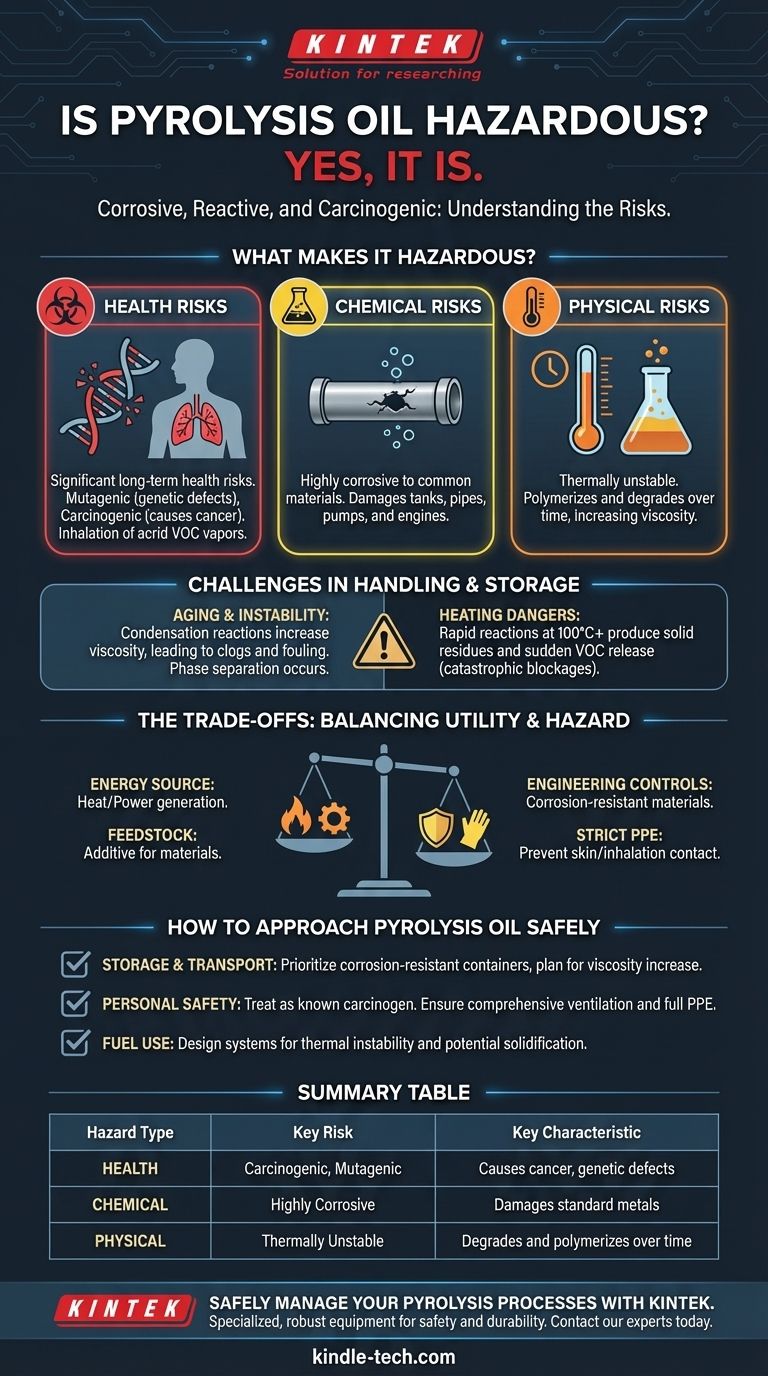

What Makes Pyrolysis Oil Hazardous?

The dangers associated with pyrolysis oil stem directly from its unique chemical composition and reactive nature. It is fundamentally different from stable fossil fuels.

An Unstable Chemical Mixture

Pyrolysis oil is a complex micro-emulsion formed by rapidly heating biomass in an oxygen-deficient environment. This process freezes a wide range of reactive, intermediate decomposition products into a liquid.

Its high oxygen content makes it prone to polymerization when exposed to air and contributes to its instability. It is not a settled substance but one that is constantly undergoing slow chemical changes.

Significant Health Risks

The most severe hazard is its toxicity. The chemical components within the oil are known to be mutagenic (can cause genetic defects) and carcinogenic (can cause cancer).

Furthermore, the oil has a distinctive "acrid smoky smell," which indicates the presence of volatile organic compounds (VOCs). Inhaling these vapors constitutes a primary route of exposure.

Corrosive Nature

Pyrolysis oil is highly corrosive to many common materials. This property poses a direct risk to the integrity of storage tanks, pipes, pumps, and engine components, requiring specialized, corrosion-resistant materials for safe handling.

Understanding the Risks in Handling and Storage

The hazardous properties of pyrolysis oil create practical challenges that must be managed carefully to ensure safety and operational reliability.

The Problem of Aging and Instability

Over time, pyrolysis oil is known to degrade. Condensation reactions between its unstable components cause a gradual increase in viscosity, and the oil can even separate into different phases.

This aging process means the oil's properties are not constant, which can clog fuel lines, foul injectors, and negatively impact system performance.

Dangers of Heating

Heating is particularly dangerous. When pyrolysis oil is heated to 100°C (212°F) or more, it undergoes rapid reactions that can produce solid residues and a sudden release of volatile organic compounds.

This behavior can lead to catastrophic blockages in fuel systems or boilers and creates a significant inhalation hazard for anyone nearby.

The Trade-offs: Balancing Utility and Hazard

Despite its hazardous nature, pyrolysis oil has valuable applications. Understanding the trade-offs is key to using it safely and effectively.

Its Value as an Energy Source

Pyrolysis oil can be burned directly in boilers and furnaces for heat and power generation. It can also serve as a feedstock or additive in the production of other materials, such as plastics.

The Necessary Precautions

The hazards do not make the oil unusable, but they demand respect. Safely handling pyrolysis oil requires specific engineering controls, such as using corrosion-resistant alloys and designing systems that can manage its instability.

For personnel, strict safety protocols, including the use of appropriate personal protective equipment (PPE) to prevent skin contact and inhalation, are non-negotiable.

How to Approach Pyrolysis Oil Safely

Your strategy for managing pyrolysis oil must be guided by your specific goal.

- If your primary focus is storage and transport: Prioritize using corrosion-resistant containers and plan for the oil's viscosity to increase over time.

- If your primary focus is personal safety: Treat it as a known carcinogen by minimizing all exposure through comprehensive ventilation and appropriate PPE for skin, eye, and respiratory protection.

- If your primary focus is using it as a fuel: Design your system to account for its thermal instability, potential to solidify when heated, and its immiscibility with fossil fuels.

Ultimately, safely unlocking the potential of pyrolysis oil requires treating it with the caution its reactive chemical nature demands.

Summary Table:

| Hazard Type | Key Risk | Key Characteristic |

|---|---|---|

| Health | Carcinogenic, mutagenic | Causes cancer, genetic defects |

| Chemical | Highly corrosive | Damages standard metals and equipment |

| Physical | Thermally unstable | Degrades and polymerizes over time |

Safely manage your pyrolysis processes with KINTEK.

Handling reactive substances like pyrolysis oil requires specialized lab equipment designed for safety and durability. KINTEK provides robust reactors, corrosion-resistant components, and safety systems tailored for advanced laboratory applications, helping you mitigate risks and achieve reliable results.

Contact our experts today to discuss your specific needs and find the right equipment for your hazardous material handling.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Thin-Layer Spectral Electrolysis Electrochemical Cell

- Lab-Scale Vacuum Induction Melting Furnace

- Custom PTFE Teflon Parts Manufacturer for PTFE Tweezers

People Also Ask

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time