Yes, sputtering is a primary method used within the broader category of Physical Vapor Deposition (PVD). It is not a separate or competing process, but rather a specific physical mechanism used to transfer atoms from a source material (the "target") onto a surface (the "substrate") to form a thin film. Sputtering is one of the most common and versatile techniques for achieving physical vapor deposition.

The core distinction is that PVD is the category of processes that physically move material in a vacuum, while sputtering is a specific method within that category that uses high-energy ion bombardment to eject atoms from a source.

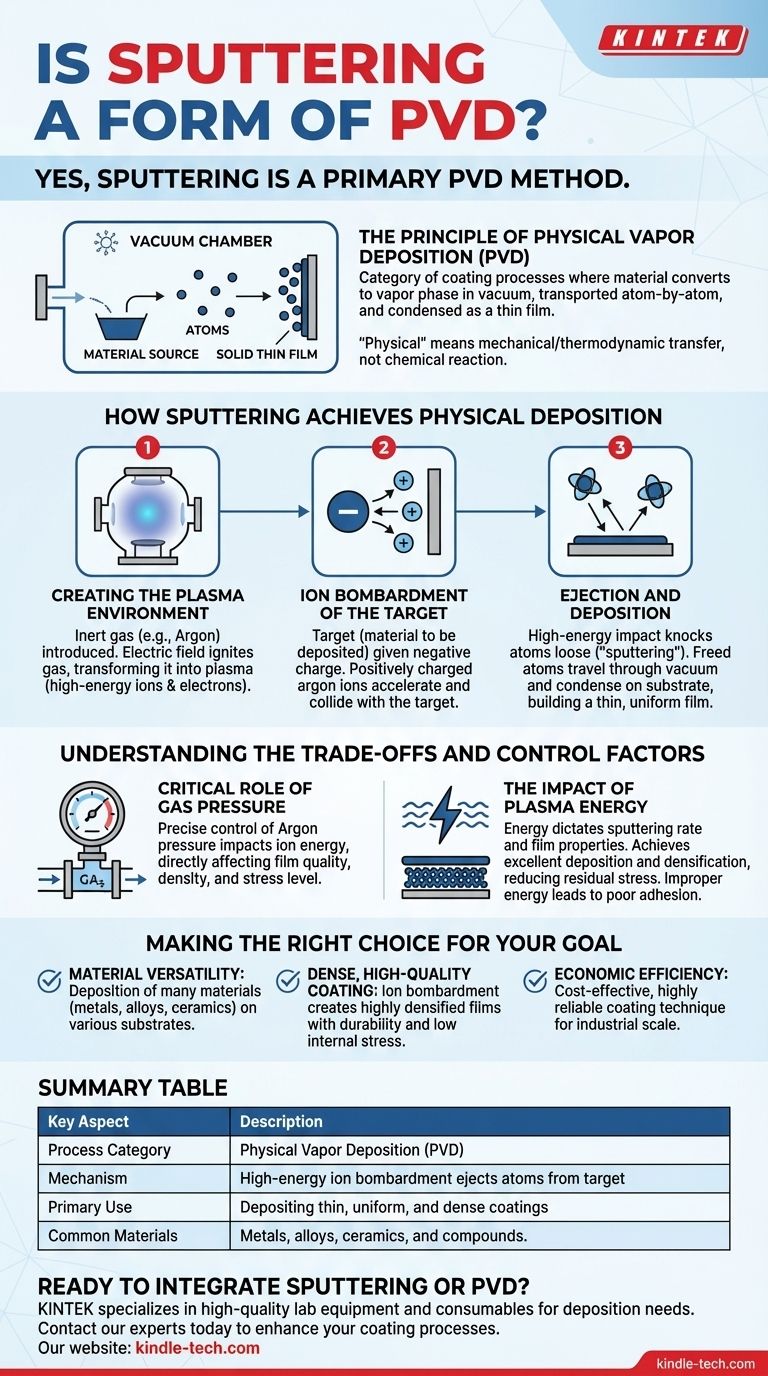

The Principle of Physical Vapor Deposition (PVD)

PVD describes a family of coating processes where a material is converted into a vapor phase in a vacuum environment, transported atom-by-atom across that vacuum, and then condensed onto a substrate as a solid, thin film. The "physical" part of the name signifies that the material transfer happens through mechanical or thermodynamic means, not a chemical reaction.

How Sputtering Achieves Physical Deposition

Sputtering is a classic example of a PVD process. It involves a series of controlled physical steps to dislodge and deposit atoms.

Step 1: Creating the Plasma Environment

The process begins by introducing an inert gas, typically argon, into a vacuum chamber. An electric field is then applied, which ignites the gas and transforms it into a plasma—a high-energy state of matter containing positively charged ions and free electrons.

Step 2: Ion Bombardment of the Target

The material to be deposited, known as the target, is given a negative electrical charge. This attracts the positively charged argon ions from the plasma, causing them to accelerate and collide with the target's surface with significant force.

Step 3: Ejection and Deposition

The high-energy impact of these ions physically knocks atoms loose from the target material. This ejection of atoms is the "sputtering" effect. These freed atoms then travel through the vacuum chamber until they land on and condense onto the substrate, gradually building up a thin, uniform film.

Understanding the Trade-offs and Control Factors

While powerful, the quality of a sputtered film is not automatic. It depends entirely on precise control over the process parameters.

The Critical Role of Gas Pressure

The pressure of the sputtering gas (argon) must be carefully controlled. Too high or too low a pressure will alter the energy of the bombarding ions, which directly impacts the quality, density, and stress level of the resulting thin film.

The Impact of Plasma Energy

The energy of the plasma dictates the sputtering rate and the properties of the deposited coating. The process achieves excellent deposition and helps densify the thin film, which can reduce residual stress and improve performance. However, improper energy levels can lead to poor adhesion or unwanted film characteristics.

Making the Right Choice for Your Goal

Understanding sputtering as a P-V-D technique helps clarify its advantages for specific applications.

- If your primary focus is material versatility: Sputtering is an excellent choice, as it allows for the deposition of a multitude of different materials, including metals, alloys, and ceramics, onto a wide variety of substrates.

- If your primary focus is creating a dense, high-quality coating: The ion bombardment inherent in sputtering helps create highly densified films, making it a superior option for applications requiring durability and low internal stress.

- If your primary focus is economic efficiency for industrial scale: Sputtering is a standard, cost-effective, and highly reliable coating technique that has been widely adopted across many industries.

By understanding sputtering as a core mechanism of PVD, you can better select the precise deposition technique for your specific material and application needs.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process Category | Physical Vapor Deposition (PVD) |

| Mechanism | High-energy ion bombardment (sputtering) ejects atoms from a target. |

| Primary Use | Depositing thin, uniform, and dense coatings on substrates. |

| Common Materials | Metals, alloys, ceramics, and other compounds. |

Ready to integrate sputtering or other PVD techniques into your lab workflow?

KINTEK specializes in high-quality lab equipment and consumables for all your deposition needs. Whether you are developing new materials or scaling up production, our expertise ensures you get the precise, reliable results your research demands.

Contact our experts today to discuss how our solutions can enhance your coating processes and drive your projects forward.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 30T 40T Split Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating