Yes, in most scenarios, sputtering is considered an expensive thin-film deposition technique. This is primarily due to the high initial capital investment required for the vacuum equipment, power supplies, and control systems. However, its true cost-effectiveness is highly dependent on the scale of production and the specific quality requirements of the application.

The core takeaway is that sputtering's high cost is an investment in precision and versatility. While the initial equipment outlay is significant, it is often justified by its unparalleled ability to produce dense, uniform, and highly adherent films from a vast range of materials.

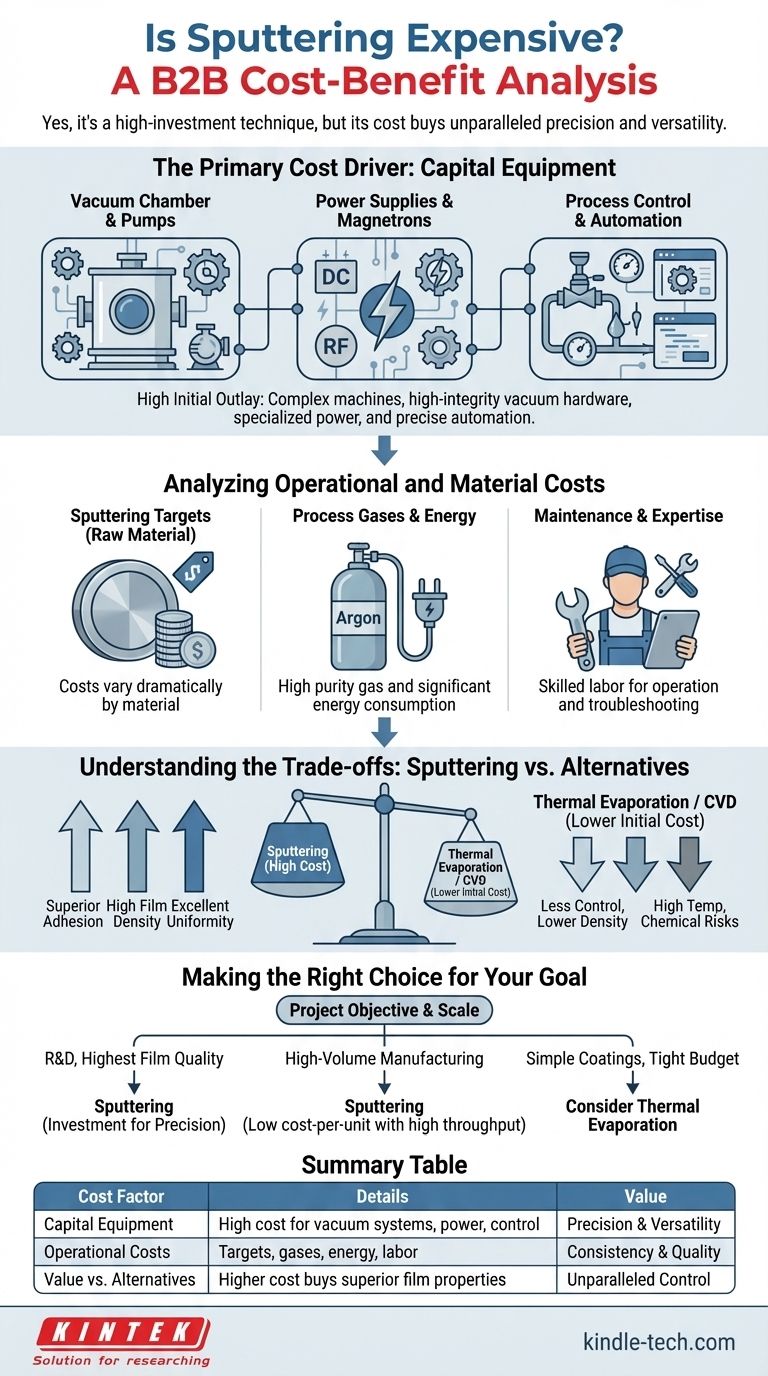

The Primary Cost Driver: Capital Equipment

The bulk of sputtering's expense comes from the initial purchase of the deposition system. These are complex machines where every component contributes to the final price tag.

The Vacuum Chamber and Pumps

Sputtering is a vacuum-based process, and creating that environment is costly. The system requires a high-integrity chamber and a series of pumps (e.g., mechanical, turbomolecular, or cryopumps) to remove atmospheric gases. This vacuum hardware is a major capital expense.

Power Supplies and Magnetrons

Generating the plasma needed to eject material from the target requires specialized power supplies. DC power supplies are used for conductive materials, while more expensive RF (radio frequency) power supplies are necessary for insulating or dielectric materials, adding to the system's cost and complexity.

Process Control and Automation

Modern sputtering systems rely on precise control over gas flow, pressure, and power. Mass flow controllers, pressure gauges, and sophisticated software are essential for creating repeatable, high-quality films, and these components add significantly to the overall cost.

Analyzing Operational and Material Costs

Beyond the initial investment, the day-to-day operational costs are a critical factor in the total expense.

Sputtering Targets (The Raw Material)

The material you intend to deposit must be formed into a high-purity sputtering target. The cost of these targets varies dramatically, from hundreds of dollars for common materials like aluminum or titanium to tens of thousands for precious metals like gold or platinum.

Process Gases and Energy

While the primary process gas, Argon, is relatively inexpensive, it must be of high purity. Furthermore, the process is energy-intensive, requiring constant power for the vacuum pumps, plasma generation, and substrate heating or cooling.

Maintenance and Expertise

Sputtering systems are not "plug-and-play" devices. They require skilled technicians for operation, routine maintenance, and troubleshooting. This specialized labor represents a significant and ongoing operational cost.

Understanding the Trade-offs: Sputtering vs. Alternatives

The high cost of sputtering is often accepted because of the unique advantages it offers over other methods.

Why Not Thermal Evaporation?

Thermal evaporation is often cheaper in terms of initial equipment cost. However, it provides less control over film structure, resulting in lower film density and weaker adhesion compared to sputtered films.

Why Not Chemical Vapor Deposition (CVD)?

CVD can produce excellent conformal coatings but often requires very high temperatures and uses volatile, sometimes hazardous, precursor chemicals. Sputtering is a physical, not chemical, process, which gives it an advantage when depositing complex alloys or materials sensitive to chemical reactions.

The Inherent Value of Sputtering's Control

You pay a premium for sputtering because you are paying for control. It allows for superior adhesion, high film density, excellent uniformity over large areas, and the ability to precisely deposit alloys and compounds with specific stoichiometry.

Making the Right Choice for Your Goal

Evaluating whether sputtering is "too expensive" depends entirely on your project's objectives and scale.

- If your primary focus is R&D or achieving the highest film quality: Sputtering's high initial cost is a necessary investment for its unparalleled process control and material versatility.

- If your primary focus is high-volume manufacturing (e.g., architectural glass): The massive capital cost of an in-line sputtering system can be justified, as the high throughput makes the cost-per-unit extremely low.

- If your primary focus is simple metallic coatings on a tight budget: A less expensive technique like thermal evaporation may be a more cost-effective starting point.

Ultimately, the cost of sputtering should be weighed against the performance, precision, and quality it uniquely delivers.

Summary Table:

| Cost Factor | Details |

|---|---|

| Capital Equipment | High cost for vacuum chambers, pumps, power supplies, and control systems. |

| Operational Costs | Includes high-purity targets, process gases, energy consumption, and skilled labor. |

| Value vs. Alternatives | Higher cost buys superior film adhesion, density, uniformity, and material versatility. |

| Cost-Effectiveness | Highly dependent on production scale; justifiable for R&D precision or high-volume manufacturing. |

Need precise, high-quality thin films for your laboratory? The initial investment in sputtering technology pays off in superior results. KINTEK specializes in lab equipment and consumables, providing solutions for all your deposition needs. Our experts can help you determine if sputtering is the right choice for your project's budget and quality requirements. Contact our team today to discuss your application and find the most cost-effective path to success.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application