Yes, there are several excellent alternatives to traditional all-porcelain crowns, each with distinct advantages in strength, aesthetics, and cost. Modern dental materials like Zirconia and E-Max offer superior durability and natural appearance, while established options like PFM and gold alloys remain highly effective for specific situations. The best choice depends entirely on the location of the tooth and your personal priorities.

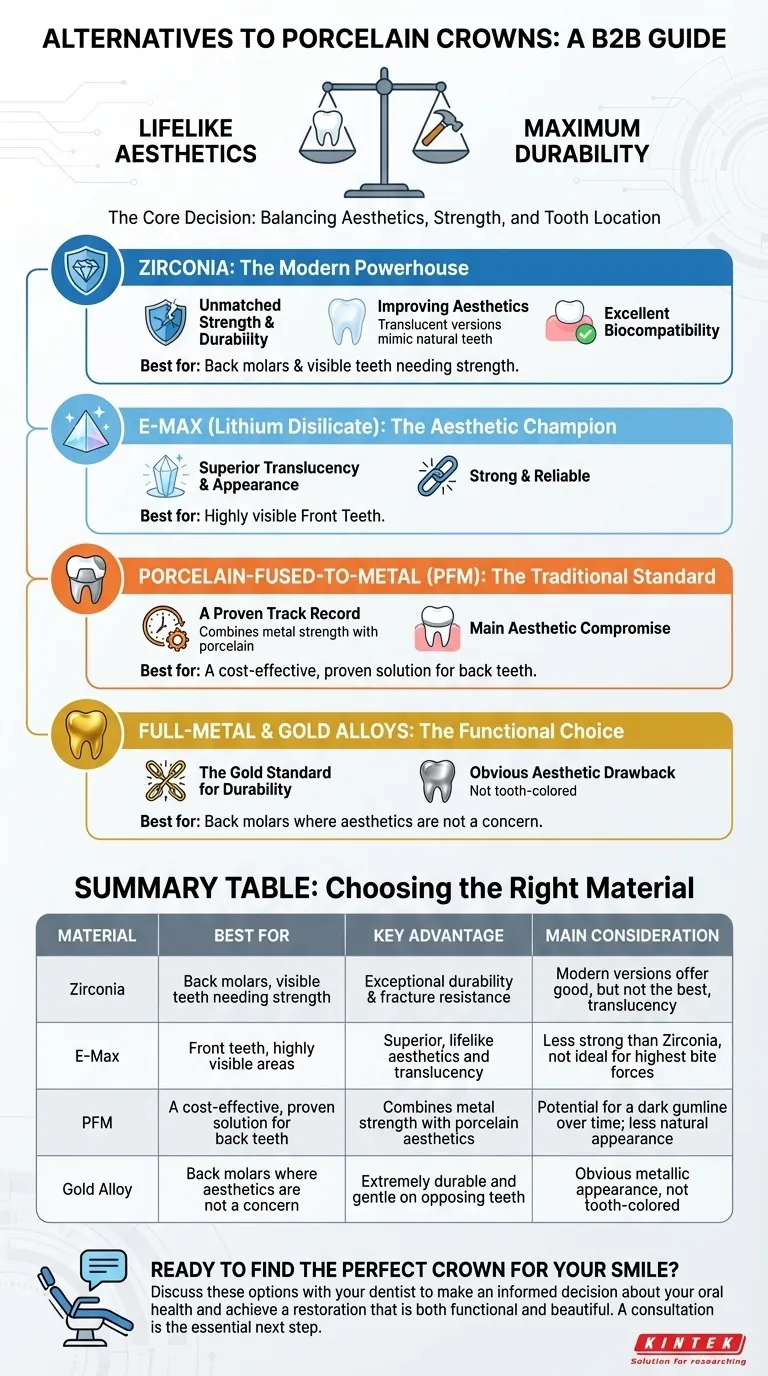

The core decision in choosing a crown material is a trade-off between lifelike aesthetics and maximum durability. While modern materials are closing this gap, understanding where your tooth is located in your mouth is the most critical factor in making the right choice.

Zirconia: The Modern Powerhouse

Zirconia is a type of ceramic that has become a dominant material in modern dentistry due to its exceptional strength and improving aesthetics. It's often considered a tooth-colored alternative to metal.

Unmatched Strength and Durability

Zirconia is incredibly resistant to chipping and fracturing, making it an ideal choice for back molars that endure immense chewing forces. Its robustness provides exceptional long-term reliability.

Improving Aesthetics

While early versions were opaque, modern translucent zirconia mimics the appearance of natural teeth much more effectively. This makes it a viable and popular option for visible teeth, not just molars.

Excellent Biocompatibility

Zirconia is highly biocompatible, meaning it integrates well with the gum tissue and is very unlikely to cause irritation or allergic reactions.

E-Max (Lithium Disilicate): The Aesthetic Champion

E-Max is a specific type of all-ceramic crown made from lithium disilicate glass. It is renowned for its outstanding appearance.

Superior Translucency and Appearance

The primary advantage of E-Max is its beauty. It has a remarkable ability to replicate the translucency and light-handling properties of natural tooth enamel, making it the premier choice for highly visible front teeth.

Strong and Reliable

While not as tough as solid zirconia, E-Max is still very strong and durable. It provides more than enough strength for incisors and canines and can often be bonded to the tooth in a way that reinforces the remaining tooth structure.

Porcelain-Fused-to-Metal (PFM): The Traditional Standard

PFM crowns have been a reliable dental solution for decades. They consist of a metal alloy substructure with a layer of porcelain fused over the top.

A Proven Track Record

PFM crowns combine the strength of metal with the aesthetics of porcelain. This hybrid approach has been tested and trusted for years, offering a predictable and durable restoration.

The Main Aesthetic Compromise

The key drawback of a PFM crown is the potential for a dark or grey line to become visible at the gumline over time. The underlying metal can also make the porcelain appear more opaque than a natural tooth.

Full-Metal and Gold Alloys: The Functional Choice

For situations where aesthetics are not a concern, full-metal crowns, particularly those made from gold alloys, are a superior functional option.

The Gold Standard for Durability

Gold alloys are incredibly strong, long-lasting, and gentle on opposing teeth. Gold wears at a rate very similar to natural enamel, preventing excessive wear on the teeth it chews against.

Obvious Aesthetic Drawback

Their non-tooth-colored appearance means they are used almost exclusively for back molars that are not visible when you smile.

Understanding the Trade-offs

Choosing a crown isn't about finding a single "best" material, but the best material for your specific clinical needs and goals.

Aesthetics vs. Strength

The classic conflict is appearance versus force resistance. E-Max offers the best aesthetics for front teeth, while Zirconia and Gold provide the brute strength needed for molars.

Location is Everything

The decision is heavily influenced by the tooth's location. A front tooth has high aesthetic demands and lower bite force, while a back molar has high bite force and low aesthetic demands.

The Role of Your Dentist

Your dentist's recommendation is crucial. They will assess the amount of remaining tooth structure, the health of your bite, and other clinical factors to advise which material will provide the most successful long-term outcome.

Making the Right Choice for Your Goal

Discuss these options with your dentist to determine the ideal path forward for your specific tooth.

- If your primary focus is the most natural, lifelike appearance for a front tooth: E-Max (lithium disilicate) is almost always the premier choice.

- If your primary focus is maximum strength and fracture resistance for a back molar: Solid Zirconia or a gold alloy crown are the strongest and most durable options.

- If your primary focus is a blend of high strength and good aesthetics for any tooth: Translucent Zirconia offers a fantastic, well-rounded solution.

- If your primary focus is a proven, cost-effective solution for a back tooth: A Porcelain-Fused-to-Metal (PFM) crown remains a reliable and valid choice.

Understanding these alternatives empowers you to have a more informed and productive conversation with your dentist about your restoration.

Summary Table:

| Crown Material | Best For | Key Advantage | Main Consideration |

|---|---|---|---|

| Zirconia | Back molars, visible teeth needing strength | Exceptional durability & fracture resistance | Modern versions offer good, but not the best, translucency |

| E-Max (Lithium Disilicate) | Front teeth, highly visible areas | Superior, lifelike aesthetics and translucency | Less strong than Zirconia, not ideal for highest bite forces |

| PFM (Porcelain-Fused-to-Metal) | A cost-effective, proven solution for back teeth | Combines metal strength with porcelain aesthetics | Potential for a dark gumline over time; less natural appearance |

| Gold Alloy | Back molars where aesthetics are not a concern | Extremely durable and gentle on opposing teeth | Obvious metallic appearance, not tooth-colored |

Ready to find the perfect crown for your smile?

This guide has outlined the key alternatives to a porcelain crown, but the best choice depends on the specific condition of your tooth and your personal goals. A consultation with your dentist is the essential next step to determine if Zirconia, E-Max, PFM, or another material is right for you.

Discuss these options with your dentist to make an informed decision about your oral health and achieve a restoration that is both functional and beautiful.

Visual Guide

Related Products

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

- 1200℃ Muffle Furnace Oven for Laboratory

- Horizontal High Temperature Graphite Vacuum Graphitization Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What would be an advantage of biomass over the use of coal? A Cleaner, Carbon-Neutral Energy Source

- What is the difference between oxidizing and reducing environments? Key Insights for Chemical Reactions

- What is the significance of using a tube furnace with vacuum-sealed quartz tubes? Master Ceramic Synthesis

- What are some positive and negative environmental effects of using biomass? A Balanced Look at a Renewable Energy Source