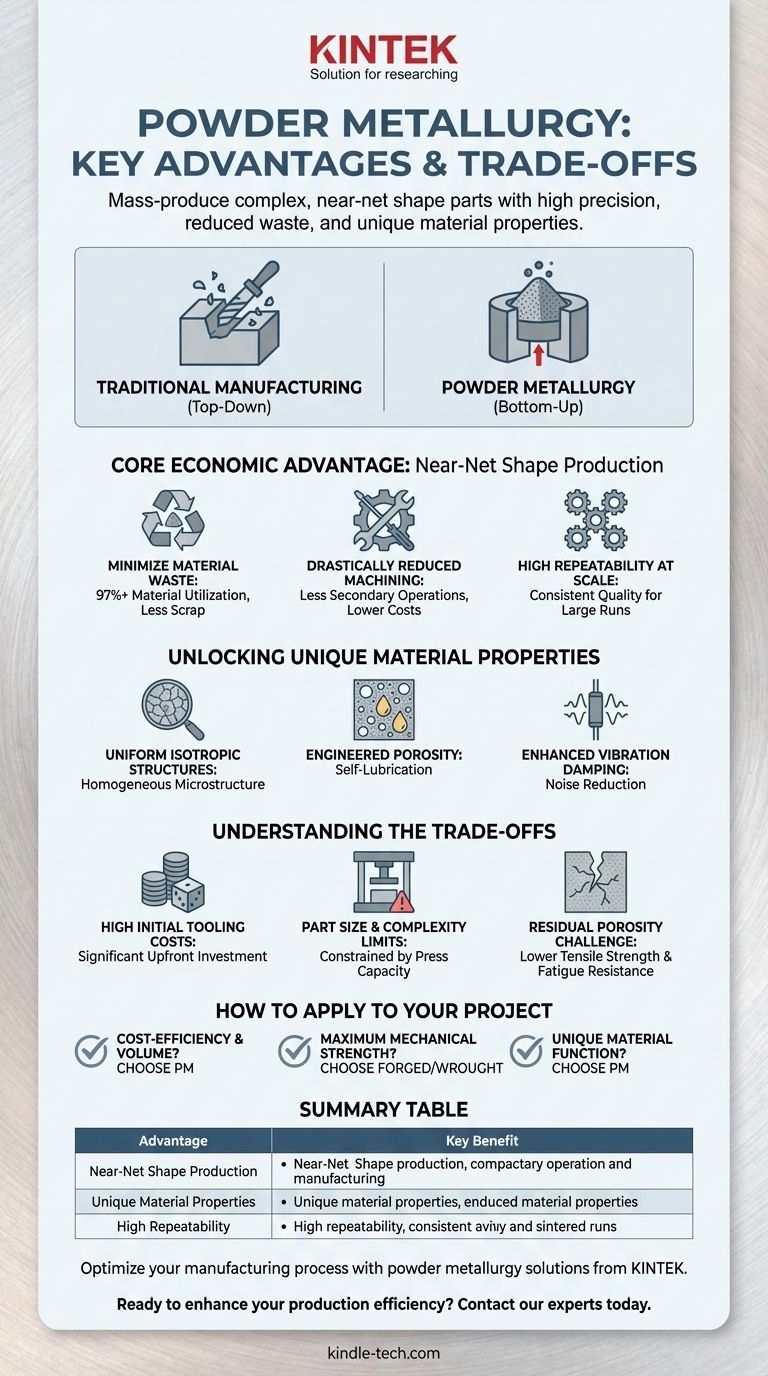

The primary advantage of powder metallurgy is its ability to mass-produce complex, near-net shape parts with high precision, which drastically reduces material waste, post-processing costs, and lead times compared to traditional subtractive methods like machining. It also unlocks the potential to create unique materials with specialized properties, such as self-lubrication, that are impossible to achieve through other means.

Where traditional manufacturing is a "top-down" process of carving a final part from a larger block of material, powder metallurgy (PM) is a "bottom-up" method of building it from the ground up. This fundamental difference makes PM exceptionally cost-effective for high-volume production of intricate components where material and machining costs are primary concerns.

The Core Economic Advantage: Near-Net Shape Production

The most significant benefit of powder metallurgy revolves around its efficiency. By pressing metal powders into a die, you create a part that is extremely close to its final, or "net," shape right from the start.

Minimizing Material Waste

Traditional machining can generate significant scrap material, which drives up costs. PM, by contrast, uses only the material needed for the part itself, often achieving over 97% material utilization.

Drastically Reducing Machining

Because parts are formed to precise dimensions, the need for costly and time-consuming secondary operations like milling, turning, or drilling is either eliminated or substantially reduced.

Achieving High Repeatability at Scale

The use of durable, reusable dies ensures that every part produced—from the first to the ten-thousandth—is virtually identical. This makes PM an ideal process for large-scale production runs where consistency is critical.

Unlocking Unique Material Properties

Powder metallurgy is not just an efficient process; it is a tool for materials engineering. It allows for the creation of components with characteristics that are difficult or impossible to replicate with casting or forging.

Creating Uniform, Isotropic Structures

Melting and casting can introduce inconsistencies, while forging creates a directional grain structure. PM consolidates powders in a solid state, resulting in a highly uniform, homogenous microstructure with isotropic properties—meaning its strength and other characteristics are the same in all directions.

Engineering Porosity for Self-Lubrication

The PM process can be controlled to create a network of interconnected pores within a part. These pores can be impregnated with lubricants, creating self-lubricating bearings and gears that are perfect for applications where regular maintenance is difficult.

Enhancing Vibration Damping

The same porosity that allows for self-lubrication also gives PM parts excellent vibration and noise-damping capabilities, a valuable trait for gears and other components in automotive and industrial machinery.

Understanding the Trade-offs

No manufacturing process is universally superior. Acknowledging the limitations of powder metallurgy is crucial for making an informed decision.

High Initial Tooling Costs

The dies, molds, and presses required for PM represent a significant upfront investment. This makes the process generally uneconomical for low-volume production or prototyping.

Limitations in Part Size and Complexity

Part size is constrained by the tonnage capacity of the compaction press. Furthermore, extremely complex geometries with undercuts or cross-holes can be difficult or impossible to produce without secondary machining.

The Challenge of Residual Porosity

While porosity can be a feature, it can also be a bug. Unless expensive secondary densification steps are used, most PM parts retain some level of porosity, which can limit their ultimate tensile strength and fatigue resistance compared to fully dense wrought or forged counterparts.

How to Apply This to Your Project

Your choice of manufacturing process must align with your project's specific goals for cost, performance, and volume.

- If your primary focus is cost-efficiency for high-volume, complex parts: PM is an exceptional choice due to its low waste and minimal need for secondary machining.

- If your primary focus is maximum mechanical strength and impact toughness: A fully dense wrought or forged component will likely outperform a standard PM part.

- If your primary focus is creating a unique material function (like self-lubrication or controlled density): PM offers capabilities that are simply not achievable with traditional subtractive methods.

By understanding its specific strengths and inherent limitations, you can leverage powder metallurgy as a powerful tool for optimized manufacturing.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Near-Net Shape Production | Reduces material waste and machining costs for high-volume runs. |

| Unique Material Properties | Enables self-lubrication, uniform isotropic structures, and vibration damping. |

| High Repeatability | Ensures consistent part quality for mass production. |

Optimize your manufacturing process with powder metallurgy solutions from KINTEK.

As a leading supplier of lab equipment and consumables, KINTEK specializes in providing the tools and expertise needed to leverage powder metallurgy for high-volume, cost-effective production of complex parts. Whether you're developing self-lubricating components or seeking to minimize material waste, our equipment ensures precision and repeatability.

Ready to enhance your production efficiency? Contact our experts today to discuss how KINTEK’s solutions can meet your specific laboratory and manufacturing needs.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- How much energy does hot isostatic pressing consume? Unlock Net Energy Savings in Your Process

- What are some of the attractive properties of hot isostatic pressed products? Achieve Perfect Density and Superior Performance

- What pressure is hot isostatic press? Achieve Full Density & Superior Material Performance

- What is the HIP material process? Achieve Near-Perfect Density and Reliability

- What is the historical background of the Hot Isostatic Pressing (HIP) process? From Nuclear Roots to Industry Standard