At its core, an acceptable leak detection method is one that reliably quantifies the integrity of a sealed system against its specific operational requirements. For vacuum systems, a primary and widely accepted method is the pressure rise rate test, which measures the increase in pressure over a set time after the system has been isolated from its pumps. This test provides a clear, quantitative measure of the total leakage into the system.

The goal of leak detection is not necessarily to find a "perfectly" sealed system, but to confirm that the total leak rate is below a threshold that would compromise your process, whether it's a vacuum furnace, a fluid line, or a high-purity gas system.

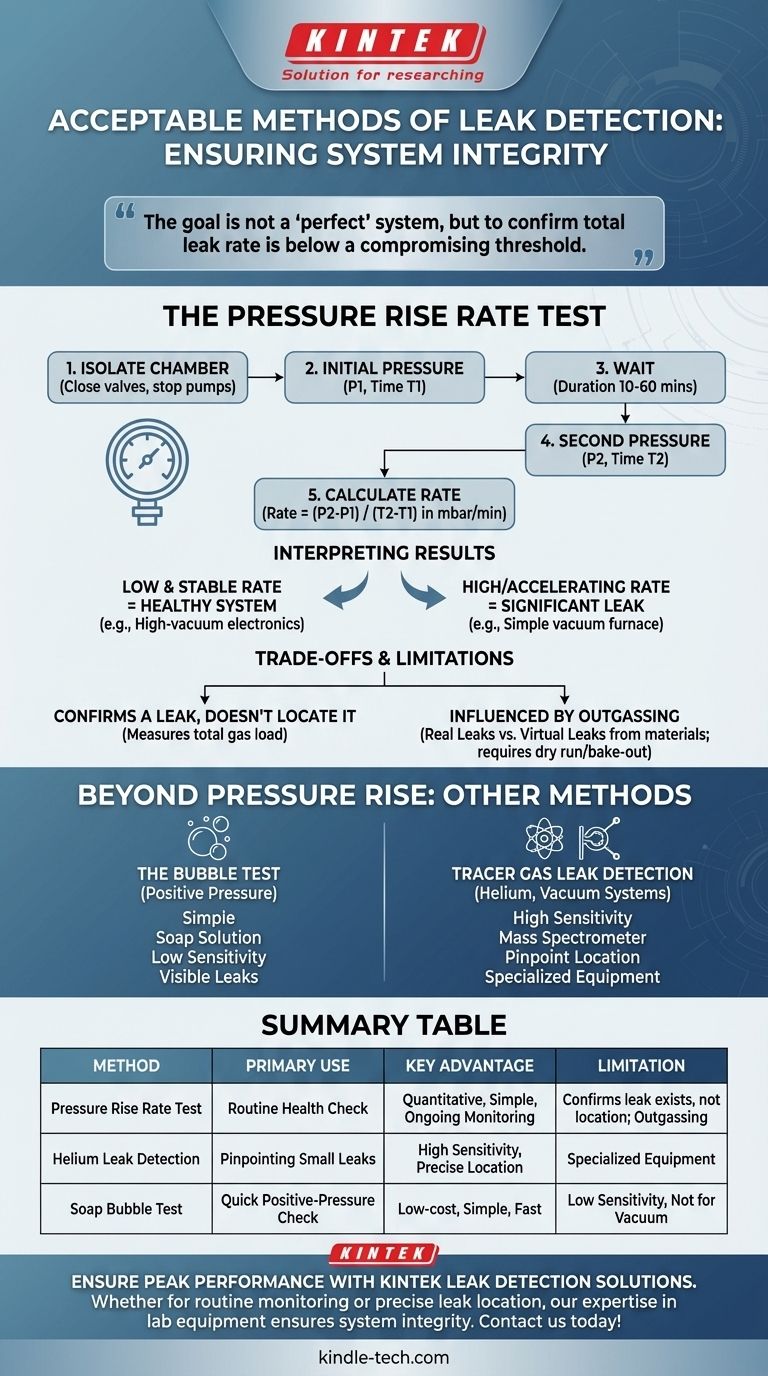

The Foundation: The Pressure Rise Rate Test

The pressure rise rate test is a fundamental health check for any vacuum system. It measures the combined effect of all leaks and outgassing sources.

The Core Procedure

The process is straightforward and methodical. First, you isolate the chamber by closing all vacuum valves connecting it to the pumping system.

After stopping the pumps, you take an initial pressure reading. You then wait for a specified duration—often between 10 minutes and one hour—and take a second pressure reading.

Calculating the Rate

The pressure rise rate is the change in pressure (ΔP) divided by the change in time (Δt).

For example, using the reference procedure, you would read the pressure at 10 minutes (P1) and again at 60 minutes (P2). The time difference is 50 minutes. The rate is (P2 - P1) / 50 minutes. This gives you a clear metric, such as millibar per minute (mbar/min).

Interpreting the Results

A low and stable pressure rise rate indicates a tight, healthy system. A high or accelerating rate points to a significant leak that requires further investigation.

The "acceptable" rate is entirely dependent on your process. A high-vacuum electronics manufacturing process will have a much stricter requirement than a simple vacuum furnace used for heat treating.

Understanding the Trade-offs and Limitations

While the pressure rise test is invaluable, it is not a complete diagnostic tool on its own. Understanding its limitations is key to using it effectively.

It Confirms a Leak, It Doesn't Locate It

The primary limitation of the pressure rise test is that it tells you that you have a leak, but not where it is. It measures the total gas load entering the chamber from all sources combined.

The Influence of Outgassing

The pressure rise in a vacuum chamber is caused by two phenomena: real leaks from the outside atmosphere and virtual leaks or outgassing from materials inside the chamber.

Outgassing is the release of trapped gases or vapors from surfaces, O-rings, or contaminants within the vacuum. This can make a tight system appear leaky, especially if it has been recently vented or contains porous materials. This is why a "dry run" is recommended for a furnace that has been shut down for an extended period—it helps bake out moisture and other volatiles.

The Need for More Sensitive Methods

For high-vacuum or ultra-high-vacuum (UHV) systems, the pressure rise method may not be sensitive enough to detect the minuscule leaks that can still disrupt a process. In these cases, a more precise tool is required.

Beyond Pressure Rise: Other Detection Methods

When the pressure rise test indicates a problem or when higher sensitivity is needed, other methods are employed to locate the source.

The Bubble Test

For systems under positive pressure, the simplest method is the bubble test. A soap solution is applied to suspected leak areas (welds, fittings), and the formation of bubbles indicates a leak. This method is simple and cheap but has very low sensitivity.

Tracer Gas Leak Detection (Helium)

For locating small leaks in vacuum systems, helium leak detection is the industry standard. This involves connecting a mass spectrometer tuned to helium to the vacuum system.

Helium is then sprayed strategically on the outside of the chamber. If helium enters through a leak, the mass spectrometer will detect it almost instantly, allowing you to precisely pinpoint the leak's location.

Making the Right Choice for Your Goal

Selecting the right method depends entirely on what you need to accomplish.

- If your primary focus is a routine health check of a vacuum system: The pressure rise rate test is the most practical and efficient method for ongoing performance monitoring.

- If your primary focus is finding the precise location of a leak in a vacuum system: A helium leak detector is the definitive tool for pinpointing the source once a leak has been confirmed.

- If your primary focus is a quick check on a positive-pressure system: The soap bubble test remains a fast, effective, and low-cost initial step.

Ultimately, a robust maintenance strategy uses these methods in combination to ensure long-term system integrity and operational success.

Summary Table:

| Method | Primary Use | Key Advantage | Limitation |

|---|---|---|---|

| Pressure Rise Rate Test | Routine health check for vacuum systems | Quantitative, simple, and effective for ongoing monitoring | Confirms a leak exists but does not locate it; influenced by outgassing |

| Helium Leak Detection | Pinpointing small leaks in vacuum systems | High sensitivity, precise location identification | Requires specialized equipment (mass spectrometer) |

| Soap Bubble Test | Quick check for positive-pressure systems | Low-cost, simple, and fast for visible leaks | Low sensitivity, not suitable for vacuum systems |

Ensure your lab equipment operates at peak performance with reliable leak detection solutions from KINTEK. Whether you need routine monitoring with pressure rise tests or precise leak location with advanced methods, our expertise in lab equipment and consumables ensures your vacuum systems, furnaces, and high-purity gas lines maintain integrity. Don't let leaks compromise your processes—contact us today to discuss your specific needs and discover how KINTEK can support your laboratory's success!

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- What is the role of standard sieves in gold scrap leaching kinetic studies? Ensure Precision in Particle Classification

- Why is sieve analysis important? Ensure Consistent Quality and Performance of Your Materials

- What is the primary function of a mechanical sieve shaker for biomass analysis? Optimize Particle Size Distribution

- How are vibratory sieve shakers and standard sieves utilized to analyze the effects of biomass torrefaction? Optimize Grindability

- What is the primary purpose of using standard sieves? Master Particle Uniformity for High-Quality Catalyst Preparation