In short, nanomaterial synthesis techniques are broadly classified into two fundamental strategies: "top-down" methods that carve nanomaterials from a larger block of material, and "bottom-up" methods that build them atom by atom. Common examples include physical and chemical vapor deposition, sol-gel processes, and mechanical methods like ball milling.

The critical insight is that no single synthesis method is universally "best." The choice is a strategic trade-off between the desired material properties, production scale, and cost, with the method itself fundamentally defining the final product's quality and characteristics.

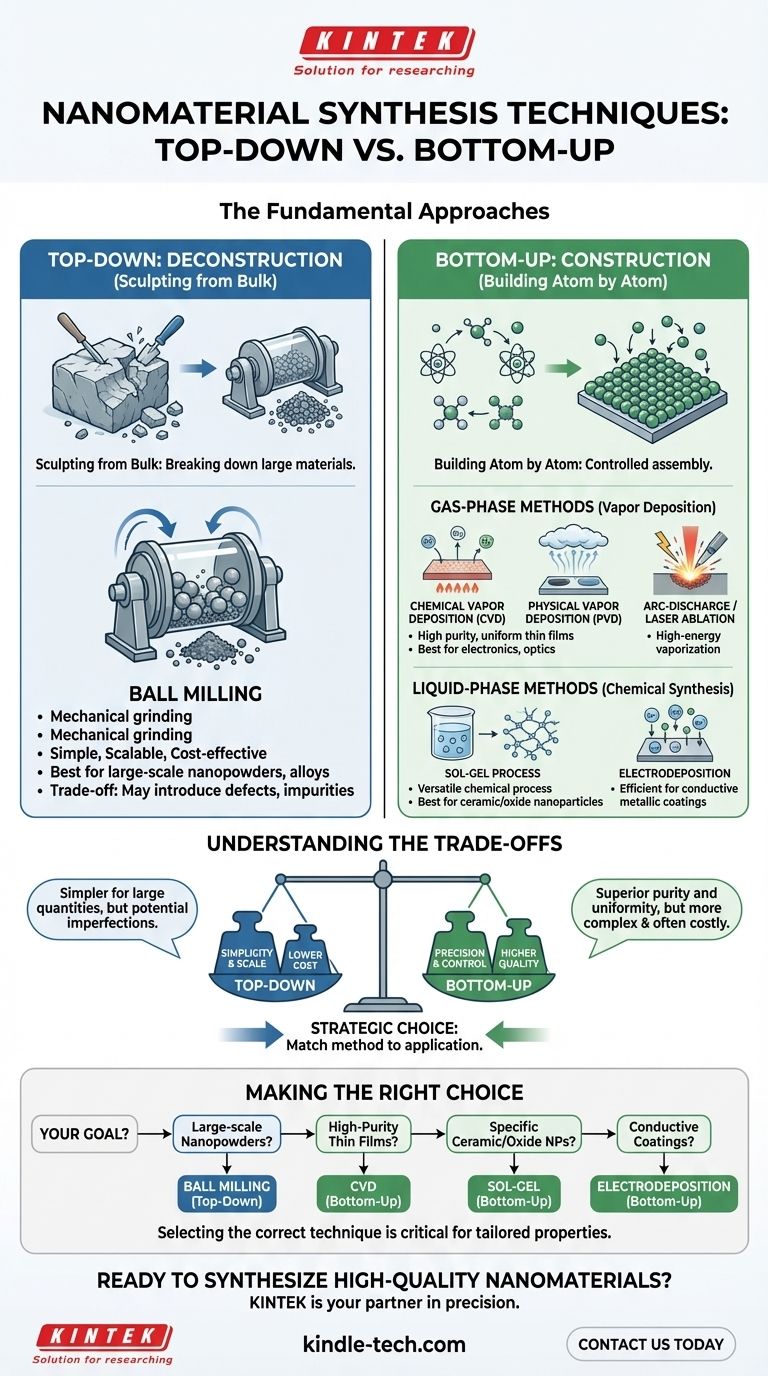

The Two Fundamental Approaches: Top-Down vs. Bottom-Up

To understand nanomaterial synthesis, it's best to think in terms of these two opposing philosophies. One is about deconstruction, the other is about construction.

Top-Down Synthesis: Sculpting from Bulk

This approach starts with a large, bulk material and breaks it down to the nanoscale. It is conceptually similar to how a sculptor carves a statue from a block of marble.

These methods are often simpler and suitable for large-scale production, but they can introduce imperfections and surface defects into the final material.

Example: Ball Milling

Ball milling is a classic top-down mechanical method. A bulk material is placed in a container with hard grinding media (balls), which is then rotated at high speed.

The repeated collisions between the balls and the material mechanically grind it down into nanoparticles.

Bottom-Up Synthesis: Building Atom by Atom

This approach is the reverse of top-down synthesis. It involves the controlled assembly of individual atoms or molecules to form more complex nanostructures.

Bottom-up methods offer exceptional precision and control over the size, shape, and composition of the nanomaterials, leading to higher-quality products.

Gas-Phase Methods (Vapor Deposition)

These techniques build materials by depositing atoms or molecules from a gaseous state onto a surface (a substrate).

Chemical Vapor Deposition (CVD) is one of the most widely used techniques for creating high-quality, uniform thin films and nanostructures. In CVD, precursor gases react on a heated substrate, depositing a solid material layer by layer.

Physical Vapor Deposition (PVD) works by physically transforming a solid source material into a vapor (e.g., through heating or sputtering), which then condenses on a substrate to form the nanomaterial.

Arc-Discharge and Laser Ablation are high-energy methods often used for carbon nanomaterials. They use an electric arc or a powerful laser, respectively, to vaporize a source material, which then condenses to form nanostructures like nanotubes or fullerenes.

Liquid-Phase Methods (Chemical Synthesis)

These techniques build nanomaterials within a liquid medium, relying on controlled chemical reactions.

Sol-Gel synthesis is a versatile wet-chemical process. It involves creating a stable liquid solution (a "sol") that is then carefully converted into a gel-like solid network, which can be further processed to yield nanoparticles or coatings.

Electrodeposition uses an electric current to reduce dissolved metal cations in a solution, causing them to deposit onto a conductive surface as a thin film or nanostructure.

Understanding the Trade-offs

Choosing a synthesis method requires a clear understanding of the compromises between cost, quality, and production scale. This is where the distinction between approaches becomes critical.

Top-Down: Simplicity vs. Imperfection

The primary advantage of methods like ball milling is their relative simplicity and scalability for producing large quantities of nanopowders.

However, the aggressive mechanical nature of this process can introduce crystallographic defects, impurities from the milling equipment, and a wide distribution of particle sizes.

Bottom-Up: Precision vs. Complexity

The key strength of methods like CVD is the high degree of control, which yields materials with superior purity, uniformity, and precisely engineered properties.

This precision comes at a cost. These systems are often more complex, operate under controlled conditions (like high vacuum or temperature), and may have slower deposition rates, making them more expensive than top-down alternatives.

Making the Right Choice for Your Goal

Your application dictates the optimal synthesis technique. There is no one-size-fits-all solution; the goal is to match the method's strengths to your specific requirements.

- If your primary focus is large-scale production of nanopowders or alloys: A top-down method like ball milling offers a cost-effective and scalable route.

- If your primary focus is high-purity, uniform thin films for electronics or optics: A bottom-up method like Chemical Vapor Deposition (CVD) is the industry standard for quality and control.

- If your primary focus is creating specific ceramic or oxide nanoparticles: The chemical flexibility of the Sol-Gel process provides a powerful pathway.

- If your primary focus is applying a conductive metallic coating: Electrodeposition is a highly efficient and well-established technique.

Ultimately, selecting the correct synthesis technique is the first and most critical step in engineering materials with precisely tailored nanoscale properties.

Summary Table:

| Synthesis Approach | Key Methods | Primary Strengths | Common Applications |

|---|---|---|---|

| Top-Down | Ball Milling | Simplicity, Scalability, Cost-Effectiveness | Large-scale nanopowder production, Alloys |

| Bottom-Up | Chemical Vapor Deposition (CVD), Sol-Gel | High Purity, Precise Control, Uniformity | High-quality thin films, Electronics, Optics |

| Bottom-Up | Physical Vapor Deposition (PVD), Electrodeposition | Efficient Coating, Conductive Layers | Metallic coatings, Conductive films |

Ready to Synthesize High-Quality Nanomaterials?

The choice of synthesis technique is critical to achieving the precise material properties your project demands. Whether you need the scalability of top-down methods or the superior control of bottom-up processes, KINTEK is your partner in precision.

We specialize in providing the advanced lab equipment—from CVD and PVD systems to ball mills and sol-gel reactors—that empowers researchers and industries to innovate at the nanoscale. Our expertise ensures you have the right tools for high-purity thin films, uniform nanoparticles, or large-scale nanopowders.

Contact us today to discuss your specific application, and let our experts help you select the ideal equipment to meet your research and production goals. Get in touch via our contact form to start the conversation.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the advantages of using HFCVD for BDD electrodes? Scaling Industrial Diamond Production Efficiently

- What is the role of the HF-CVD system in preparing BDD electrodes? Scalable Solutions for Boron-Doped Diamond Production

- What is the hot filament chemical vapour deposition of diamond? A Guide to Synthetic Diamond Coating

- What is the specific function of the metal filament in HF-CVD? Key Roles in Diamond Growth

- How are reactants introduced into the reaction chamber during a CVD process? Mastering Precursor Delivery Systems