Mill balls are engineered from a specific range of materials, each chosen for its unique physical and chemical properties. The most common materials include high-density metals like steel and tungsten carbide, and hard ceramics such as zirconia, alumina, and silicon nitride. For specialized applications where purity is paramount, natural materials like agate are also used.

The choice of mill ball material is a critical decision that dictates the efficiency of the grinding process, the potential for sample contamination, and the overall cost. Understanding the properties of each material allows you to match the grinding media directly to the requirements of your sample and the goals of your analysis.

The Role of Grinding Media

A ball mill works by tumbling grinding media (the balls) with a sample material inside a rotating chamber. The balls crush and grind the material through repeated impact and attrition. The properties of these balls are therefore central to the entire process.

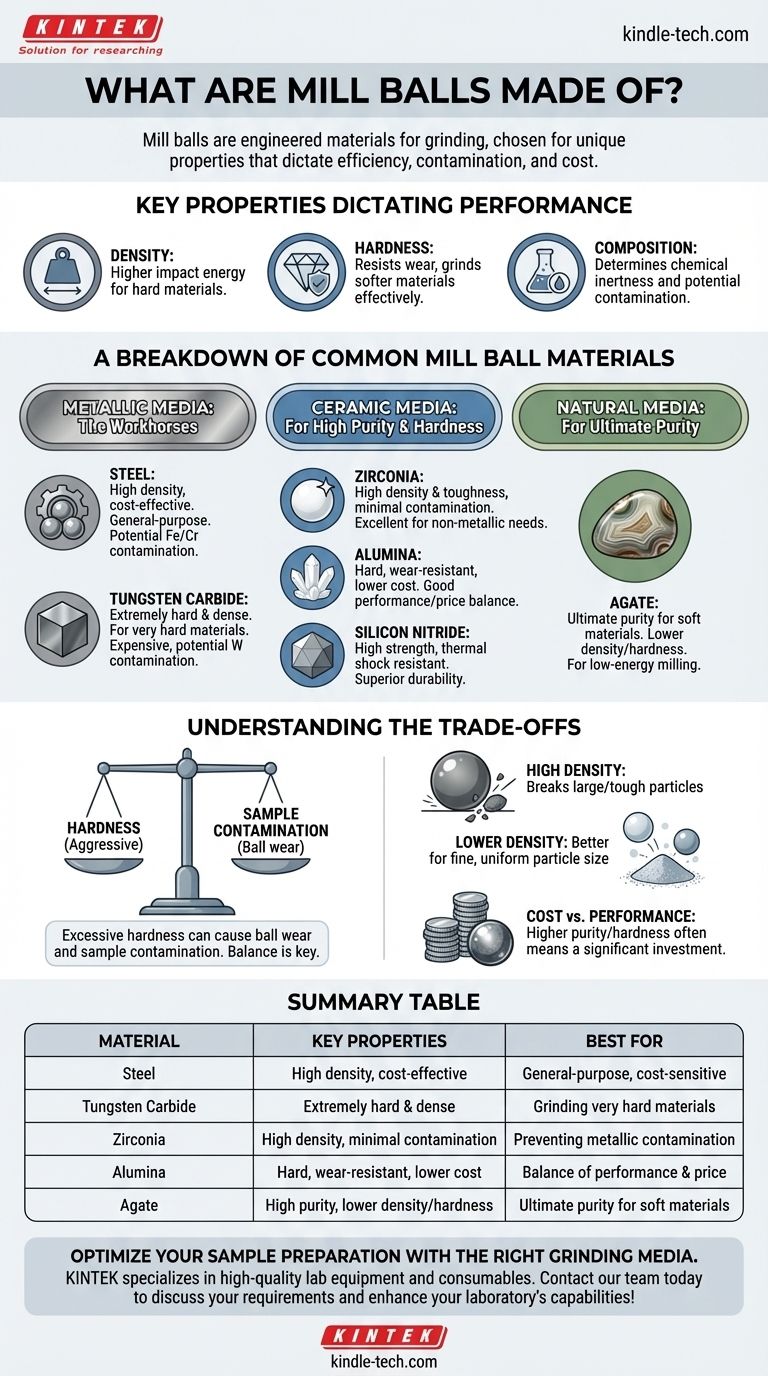

Key Properties Dictating Performance

The effectiveness of a mill ball is determined by three primary characteristics:

- Density: Higher density balls deliver more energy per impact, leading to more efficient grinding of hard or tough materials.

- Hardness: A harder ball will resist wear and can effectively grind materials that are softer than itself. This is often measured on the Mohs or Vickers scale.

- Composition: The material of the ball determines its chemical inertness and the type of contamination it might introduce into the sample.

A Breakdown of Common Mill Ball Materials

The material you choose is a direct function of the material you need to grind and your tolerance for contamination.

Metallic Media: The Workhorses

Steel balls, typically made of chrome steel or stainless steel, are the most common choice for general-purpose grinding. They are high-density, tough, and cost-effective. Their primary drawback is the potential for iron and chrome contamination.

Tungsten Carbide is significantly denser and harder than steel. It is used for grinding extremely hard materials where the high energy impact is necessary. It is, however, much more expensive and can introduce tungsten contamination.

Ceramic Media: For High Purity and Hardness

Zirconia (Zirconium Oxide) is a very popular ceramic media. It combines high density (for a ceramic), exceptional toughness, and high wear resistance, resulting in minimal contamination. It is an excellent choice when metallic contamination must be avoided.

Alumina (Aluminum Oxide) is another widely used ceramic. While less dense than zirconia, it is extremely hard and offers excellent wear resistance at a lower cost, making it a good balance of performance and price for many applications.

Silicon Nitride is a high-performance ceramic known for its high strength, toughness, and excellent thermal shock resistance. It is lighter than zirconia but offers superior durability in many demanding environments.

Natural Media: For Ultimate Purity

Agate is a form of microcrystalline quartz. These balls are used when preventing any form of contamination is the absolute highest priority. They have lower density and hardness, making them suitable only for softer materials and lower-energy milling.

Understanding the Trade-offs

Choosing a mill ball material is always an exercise in balancing competing factors.

Hardness vs. Sample Contamination

The grinding media must be harder than the material being ground. However, using an excessively hard or aggressive media can cause it to wear or even fracture, introducing fragments of the ball itself into your sample. This is why you must avoid steel balls if you are performing trace metal analysis for iron.

Density vs. Particle Size

High-density balls (like steel or tungsten carbide) are excellent for breaking down large, tough particles. However, this high impact energy can be detrimental for finer grinding or for brittle materials, where it may cause unwanted fracturing or amorphization instead of controlled size reduction. Lighter ceramic balls often provide better results for achieving a fine, uniform particle size.

Cost vs. Performance

There is a direct correlation between cost and performance. Steel balls are economical for bulk processing. High-purity zirconia or tungsten carbide balls, however, represent a significant investment that is only justified by the need for minimal contamination or the grinding of exceptionally hard materials.

Selecting the Right Ball Material for Your Goal

Your choice should be guided by a clear understanding of your primary objective.

- If your primary focus is cost-effective bulk grinding: Steel is often the most practical choice, assuming minor iron contamination is acceptable.

- If your primary focus is grinding very hard materials: Tungsten carbide offers the necessary hardness and density, though at a higher cost.

- If your primary focus is preventing metallic contamination: Zirconia or alumina balls are the standard, with zirconia offering higher density for more efficient grinding.

- If your primary focus is ultimate purity for soft materials: Agate is the ideal choice for low-energy milling where preventing any contamination is critical.

Ultimately, selecting the correct mill ball material transforms grinding from a brute-force process into a precisely controlled engineering task.

Summary Table:

| Material | Key Properties | Best For |

|---|---|---|

| Steel | High density, cost-effective | General-purpose grinding, cost-sensitive applications |

| Tungsten Carbide | Extremely hard and dense | Grinding very hard materials |

| Zirconia | High density & hardness, minimal contamination | Preventing metallic contamination, efficient grinding |

| Alumina | Hard, wear-resistant, lower cost | Balance of performance and price, non-metallic grinding |

| Agate | High purity, lower density/hardness | Ultimate purity for soft materials, trace analysis |

Optimize your sample preparation and achieve precise results with the right grinding media. The choice of mill ball material is critical for efficient grinding and preventing contamination. KINTEK specializes in high-quality lab equipment and consumables, including a full range of grinding media for any application. Our experts can help you select the perfect mill balls for your specific needs. Contact our team today to discuss your requirements and enhance your laboratory's capabilities!

Visual Guide

Related Products

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Single Horizontal Jar Mill

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- Laboratory Horizontal Planetary Ball Mill Milling Machine

People Also Ask

- What is the average speed of a ball mill? Optimize Grinding with Critical Speed Calculations

- What are the disadvantages of a ball mill? High Energy Use, Noise, and Contamination Risks

- What affects ball mill efficiency? Optimize Grinding Speed, Media, and Material for Peak Performance

- What are the factors affecting grinding efficiency? Optimize Your Process for Maximum Output

- Why are excellent sealing and corrosion resistance required for WC-10Co ball milling? Ensure High-Purity Mixing Results