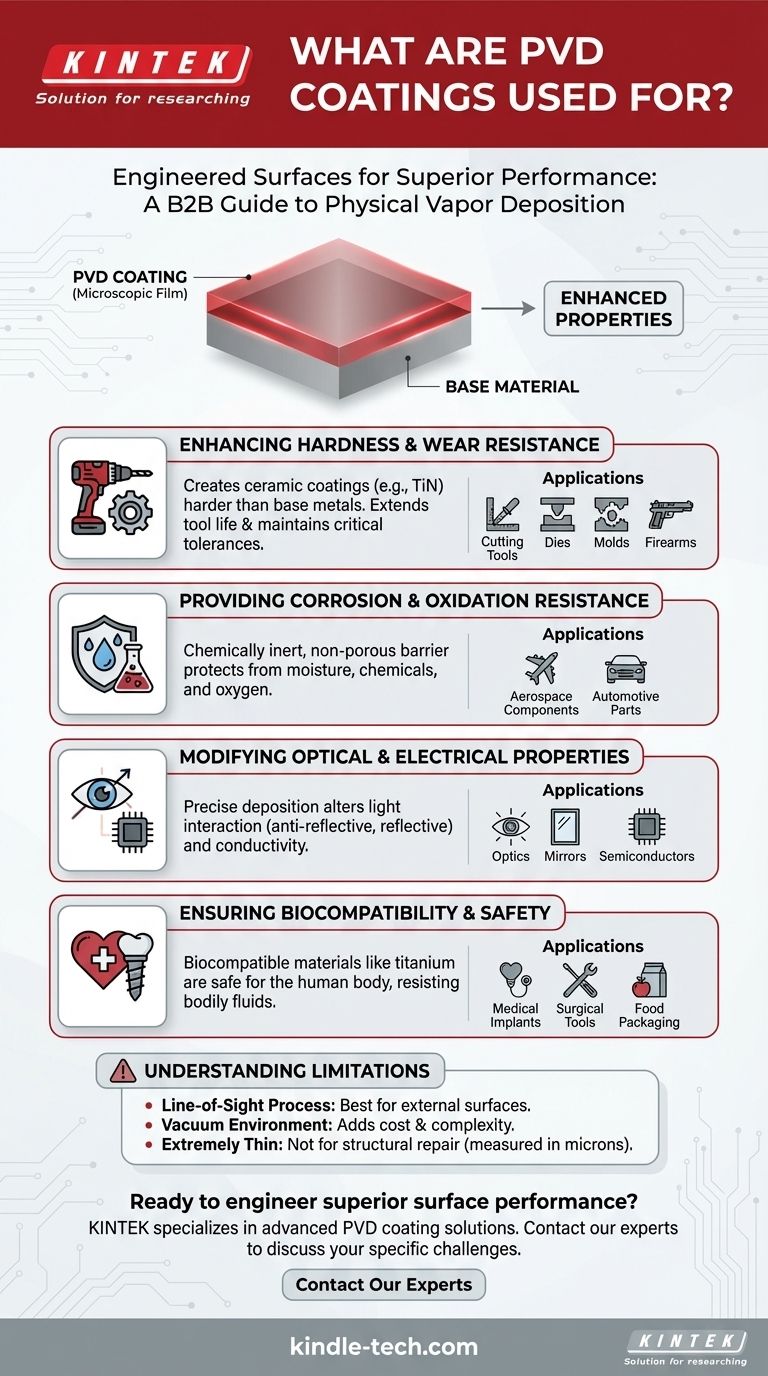

In essence, Physical Vapor Deposition (PVD) coatings are used to apply a very thin, high-performance film onto a surface to drastically improve its properties. This process is chosen for a vast range of applications—from aerospace components and medical implants to cutting tools and optics—where enhanced hardness, wear resistance, corrosion resistance, or specific optical and electrical characteristics are required.

The core function of PVD is not defined by a single industry, but by its ability to engineer a material's surface. It acts as a microscopic layer of armor or a functional film, giving an ordinary object extraordinary capabilities without changing its underlying structure.

Why PVD is So Versatile: Enhancing Surface Properties

The reason PVD technology appears in so many disparate fields is that it fundamentally improves the surface of a component. Different coating materials can be selected to achieve specific, targeted enhancements.

Enhancing Hardness and Wear Resistance

PVD is renowned for creating extremely hard ceramic coatings, such as Titanium Nitride (TiN). These coatings are significantly harder than most base metals.

This added hardness directly translates to exceptional wear and abrasion resistance. It allows tools and components to maintain their sharp edges and critical tolerances for much longer.

This is the primary reason PVD is used on cutting tools, dies, molds for material processing, and firearms, where friction and wear are the main causes of failure.

Providing Corrosion and Oxidation Resistance

Many PVD coatings are chemically inert and form a dense, non-porous barrier between the substrate and the environment.

This barrier effectively seals the surface, protecting it from moisture, chemicals, and oxygen that would otherwise lead to corrosion or oxidation.

Applications in the aerospace industry (e.g., on turbine blades) and the automotive sector rely on this property to ensure component longevity in harsh operating conditions.

Modifying Optical and Electrical Properties

PVD is not limited to mechanical protection. The process allows for the precise deposition of materials that alter how a surface interacts with light and electricity.

This includes creating anti-reflective coatings for optics and vision devices, reflective layers for mirrors, and even transparent conductive films used in electronics.

In semiconductors, PVD is used to lay down the ultra-thin aluminum tracks and ceramic resistors that form the basis of electronic circuitry.

Ensuring Biocompatibility and Safety

Certain PVD materials, like titanium, are highly biocompatible, meaning they do not provoke an adverse reaction when introduced to the human body.

This makes PVD an essential process for coating medical implants and surgical tools, ensuring they are safe, durable, and resistant to corrosion from bodily fluids.

This principle of creating an inert barrier also extends to applications like food packaging, where thin films prevent interaction between the product and its container.

Understanding the Limitations of PVD

While incredibly versatile, PVD technology has inherent characteristics that make it unsuitable for certain applications. Understanding these trade-offs is crucial for proper implementation.

It is a Line-of-Sight Process

The vaporized coating material travels in a straight line from the source to the substrate. This means PVD is excellent for coating external surfaces but struggles to coat complex internal geometries or deep, narrow holes.

It Requires a Vacuum Environment

The entire PVD process must take place in a high-vacuum chamber to prevent the coating material from reacting with particles in the air. This requirement adds to the cost and complexity of the equipment and process.

The Coatings Are Extremely Thin

PVD films are typically measured in microns (thousandths of a millimeter). While they add incredible surface properties, they do not add structural strength and are not suitable for repairing significant surface damage or wear.

How to Determine if PVD is Right for Your Application

Choosing a surface treatment depends entirely on your primary engineering goal.

- If your primary focus is extending tool life and performance: PVD is an industry standard for adding hardness and wear resistance to cutting tools, dies, and molds.

- If your primary focus is protecting components from harsh environments: The corrosion and oxidation resistance offered by PVD is ideal for aerospace, automotive, and industrial parts.

- If your primary focus is medical safety and biocompatibility: PVD is the superior choice for coating surgical instruments and long-term medical implants.

- If your primary focus is engineering specific light or electrical behavior: PVD provides the precision needed for creating anti-reflective coatings, mirrors, and semiconductor components.

Ultimately, PVD is the definitive choice when you need to fundamentally upgrade the surface performance of a component without altering its core material.

Summary Table:

| Key Property | Primary Application | Common Use Cases |

|---|---|---|

| Hardness & Wear Resistance | Extending Tool Life | Cutting tools, dies, molds, firearms |

| Corrosion & Oxidation Resistance | Protection in Harsh Environments | Aerospace components, automotive parts |

| Optical & Electrical Properties | Controlling Light & Electricity | Anti-reflective coatings, mirrors, semiconductors |

| Biocompatibility | Medical Safety | Surgical tools, implants, food packaging |

Ready to engineer superior surface performance for your components? KINTEK specializes in advanced PVD coating solutions that deliver exceptional hardness, corrosion resistance, and specialized functional properties. Whether you're developing cutting tools, medical implants, or precision optics, our expertise can help you achieve longer-lasting, higher-performing products. Contact our experts today to discuss how our PVD coatings can solve your specific challenges and add value to your applications.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition