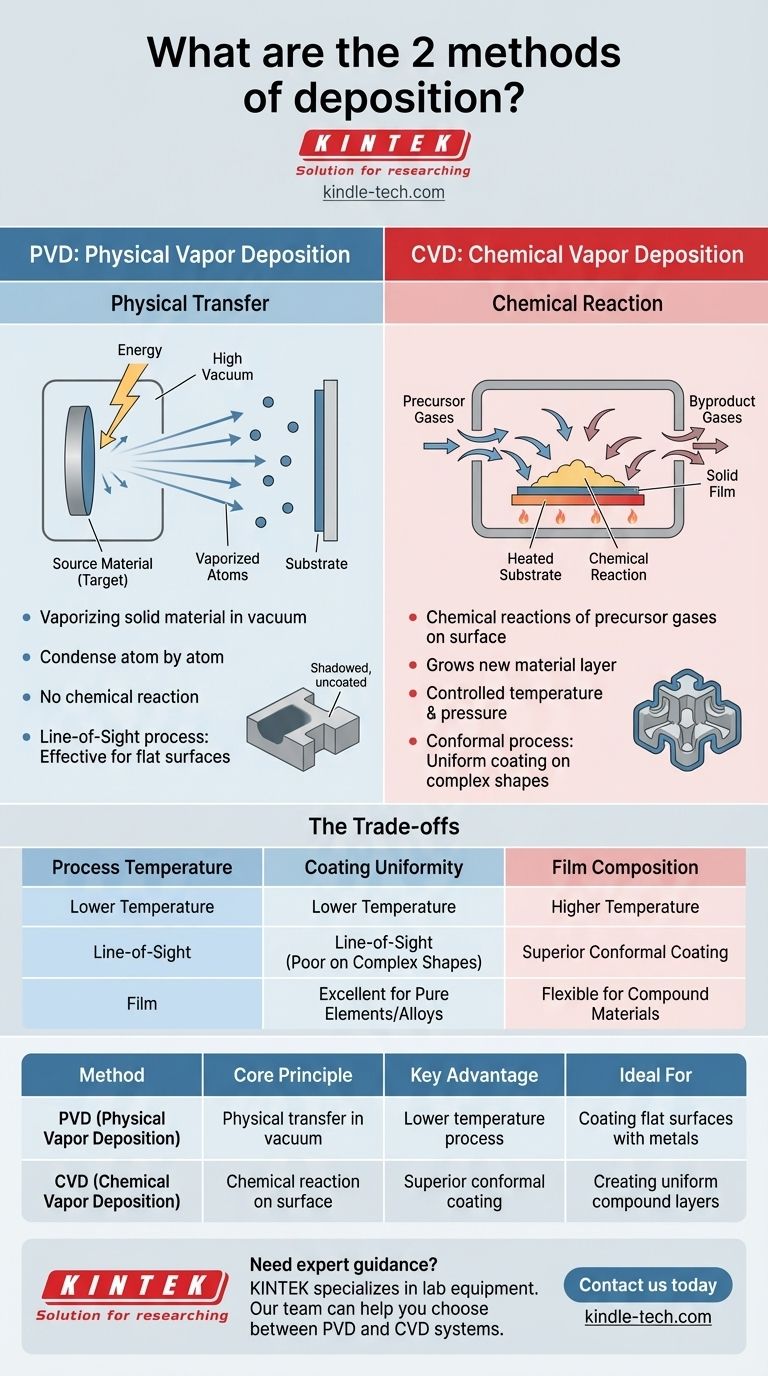

The two primary methods for creating the ultra-thin films essential to modern electronics and materials are Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD). PVD works by vaporizing a solid material in a vacuum and allowing it to condense onto a substrate, effectively "painting" it atom by atom. In contrast, CVD uses chemical reactions between precursor gases on the substrate's surface to grow a new, solid film.

The critical distinction lies in the process itself: Physical Vapor Deposition (PVD) is a physical transfer of material from a source to a target, while Chemical Vapor Deposition (CVD) is a chemical reaction that creates an entirely new material on the surface.

Unpacking Physical Vapor Deposition (PVD)

The Core Principle: A Physical Transfer

PVD is a process that moves material on an atomic level without changing its chemical composition. It involves taking a solid source material, known as the "target," and turning it into a vapor.

This vapor then travels across a chamber and condenses on the target object, known as the "substrate," forming a thin, solid film. The process does not involve any chemical reactions.

The Role of High Vacuum

PVD must be conducted under high or even ultra-high vacuum conditions.

This vacuum is critical for two reasons. First, it removes air and other particles that could contaminate the film. Second, it ensures the vaporized atoms can travel from the source to the substrate without colliding with other gas molecules.

Key Characteristics

Because the vaporized atoms travel in a straight line, PVD is considered a line-of-sight process. This makes it extremely effective for coating flat surfaces but can present challenges for coating complex, three-dimensional shapes uniformly.

Understanding Chemical Vapor Deposition (CVD)

The Core Principle: A Chemical Reaction

CVD is fundamentally a chemical process. It begins by introducing one or more volatile precursor gases into a reaction chamber containing the substrate.

When these gases come into contact with the heated substrate, they react or decompose, leaving behind a solid material that forms the desired film. This process literally grows a new material layer on the substrate's surface.

The Process Environment

While CVD processes also take place in a controlled chamber, the key is the precise management of reactant gases, pressure, and temperature to drive the specific chemical reaction needed.

This allows for the creation of very high-purity and high-performance films, as unwanted byproducts of the reaction can be removed as gases.

Key Characteristics

Because the film is formed by gases reacting on a surface, CVD is not a line-of-sight process. The precursor gases can flow around and into complex geometries, resulting in highly uniform, or conformal, coatings even on intricate surfaces.

Understanding the Trade-offs

Process Temperature

CVD processes often require high substrate temperatures to initiate and sustain the necessary chemical reactions. This can limit the types of materials that can be used as substrates. PVD, in many cases, can be performed at lower temperatures.

Coating Uniformity (Conformality)

For coating complex, non-flat surfaces, CVD is generally superior. Its gas-phase nature allows it to deposit a uniform layer over an entire surface. PVD's line-of-sight nature means "shadowed" areas of a complex object may receive little to no coating.

Film Composition

PVD is excellent for depositing pure elements and some alloys, as it directly transfers the source material. CVD offers greater flexibility for creating complex compound materials (like silicon nitride or titanium carbide) by precisely controlling the mix of reactant gases.

Making the Right Choice for Your Goal

The decision between PVD and CVD depends entirely on the material you need to deposit and the shape of the object you are coating.

- If your primary focus is depositing a pure metal onto a flat surface at lower temperatures: PVD is often the most direct and efficient method.

- If your primary focus is creating a uniform, high-purity compound layer on a complex shape: CVD provides the conformal coating and chemical precision required for the task.

Understanding this fundamental difference between physical transfer and chemical creation is the key to selecting the optimal deposition method for your application.

Summary Table:

| Method | Core Principle | Key Advantage | Ideal For |

|---|---|---|---|

| PVD (Physical Vapor Deposition) | Physical transfer of material in vacuum | Lower temperature process, excellent for pure elements | Coating flat surfaces with metals and alloys |

| CVD (Chemical Vapor Deposition) | Chemical reaction on substrate surface | Superior conformal coating on complex shapes | Creating uniform compound layers on intricate parts |

Need expert guidance on selecting the right deposition method for your specific application? KINTEK specializes in lab equipment and consumables, serving all your laboratory needs. Our team can help you choose between PVD and CVD systems to achieve optimal thin film results for your research or production. Contact us today to discuss your project requirements!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is a CVD coating? A Guide to Durable, Conformal Surface Engineering

- What is low pressure chemical vapor deposition LPCVD? Achieving Superior Uniform Thin Films

- What is the CVD process in diamond? Grow Pure Diamonds from Gas in a Lab

- What is the thickness of CVD coating? Optimize Wear Resistance with Ultra-Thin Films

- What is the principle of MOCVD? A Guide to High-Purity Thin Film Deposition

- Why is a substrate stage cooling system critical in high-power density plasma CVD? Master Extreme Thermal Management

- How does the hydrogen and nitrogen mixed atmosphere influence graphene morphology? Master CVD Synthesis Control

- What is the working of CVD technique? A Step-by-Step Guide to Chemical Vapor Deposition