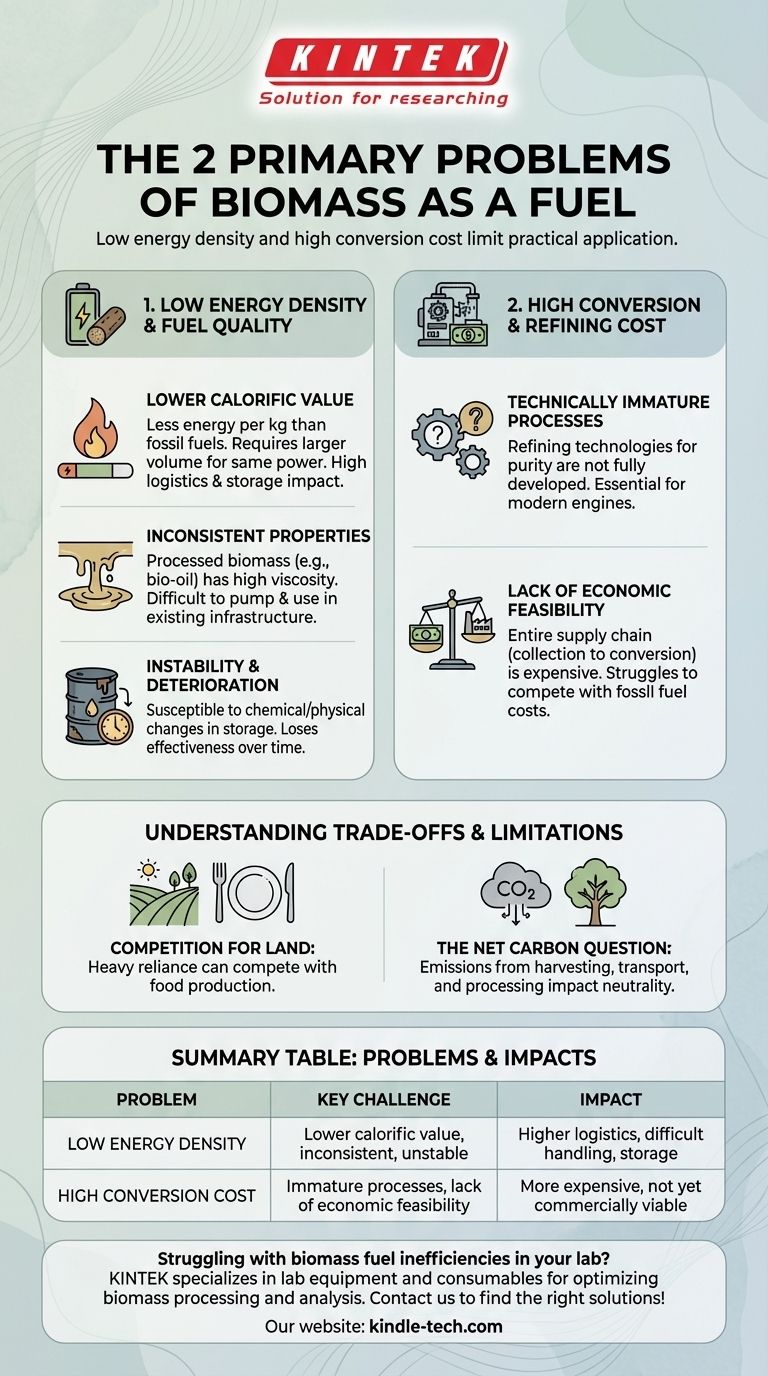

The two primary problems of biomass as a fuel are its low energy density and the high cost associated with converting it into a usable, stable energy source. Unlike energy-rich fossil fuels, raw biomass contains less energy per unit of mass and possesses challenging physical properties, while the refining processes required to upgrade it are often technologically immature and not yet economically feasible.

While biomass is a renewable resource, its practical application is fundamentally limited by two factors: the fuel's inherent inefficiency and the complex, expensive processes required to transform it from raw organic matter into a high-quality energy product.

The Challenge of Energy Density and Fuel Quality

One of the most significant scientific hurdles for biomass is its composition. Compared to the highly concentrated energy in fossil fuels, biomass is less potent and far more difficult to handle in its raw or minimally processed forms.

Lower Calorific Value

Biomass simply contains less energy per kilogram than traditional fuels. This lower energy density means you must transport, store, and process a much larger volume of material to generate the same amount of power as coal or oil, which has significant logistical and cost implications.

Inconsistent Physical Properties

Processed biomass, such as bio-oil, often has problematic characteristics. Its high viscosity makes it thick and difficult to pump through existing pipelines and engines designed for conventional fuels.

Instability and Deterioration

Many forms of processed biomass are not stable over long periods. Bio-oils, for example, are susceptible to chemical and physical changes during storage, causing them to degrade and lose effectiveness, unlike the remarkable stability of fossil fuels.

The High Cost of Conversion and Refining

The second major barrier is economic and technological. Turning crops, wood, or waste into a consistent, energy-dense fuel is a complex undertaking that struggles to compete on cost with established fossil fuel infrastructure.

Technically Immature Processes

The technologies for refining and purifying biomass derivatives like bio-oil are not yet mature. These processes are essential for removing impurities and creating a fuel that can work in modern engines without causing damage.

Lack of Economic Feasibility

Ultimately, the cost is a prohibitive factor. The entire supply chain—from collecting and transporting the raw biomass to the energy-intensive conversion process—often makes the final product more expensive than its fossil fuel equivalent.

Understanding the Trade-offs

Viewing biomass as a perfect green solution is a common oversimplification. Its implementation involves critical trade-offs that are often overlooked.

Competition for Land and Resources

A heavy reliance on energy crops for biomass can create competition for arable land that would otherwise be used for food production. This can impact food prices and land use, potentially leading to deforestation if not managed carefully.

The Net Carbon Question

While burning biomass releases carbon that was recently captured from the atmosphere, it isn't automatically "carbon neutral." The energy required for harvesting, transportation, and processing all generates emissions, and the net carbon benefit depends heavily on the specific source and supply chain.

Making the Right Choice for Your Goal

Understanding these challenges is not meant to dismiss biomass, but to apply it intelligently where it makes the most sense.

- If your primary focus is a large-scale, drop-in replacement for fossil fuels: Be aware that biomass currently faces significant hurdles in terms of energy density, cost, and technological readiness.

- If your primary focus is localized energy from waste streams: Biomass can be an exceptionally effective solution, as it utilizes locally available material, minimizes transportation costs, and solves a waste disposal problem.

By recognizing its limitations, we can better harness the true potential of biomass as a valuable component of a diversified energy future.

Summary Table:

| Problem | Key Challenge | Impact |

|---|---|---|

| Low Energy Density | Lower calorific value, inconsistent properties, instability | Higher logistics costs, difficult to handle and store |

| High Conversion Cost | Technically immature processes, lack of economic feasibility | More expensive than fossil fuels, not yet commercially viable |

Struggling with biomass fuel inefficiencies in your lab? KINTEK specializes in lab equipment and consumables that help you optimize biomass processing and analysis. From precise calorimeters to advanced conversion reactors, our solutions are designed to enhance your research efficiency and accuracy. Contact us today to find the right equipment for your biomass energy projects!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

People Also Ask

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time