In short, Electron Beam Machining (EBM) offers exceptional precision for cutting or drilling complex features in nearly any metal, regardless of its hardness. However, its significant disadvantages—namely extremely high equipment costs, the need for a vacuum chamber, and safety considerations—make it a highly specialized process reserved for specific, high-value applications.

The core decision of whether to use EBM comes down to a simple trade-off: you gain unparalleled precision and material versatility at the expense of high cost, operational complexity, and significant physical constraints.

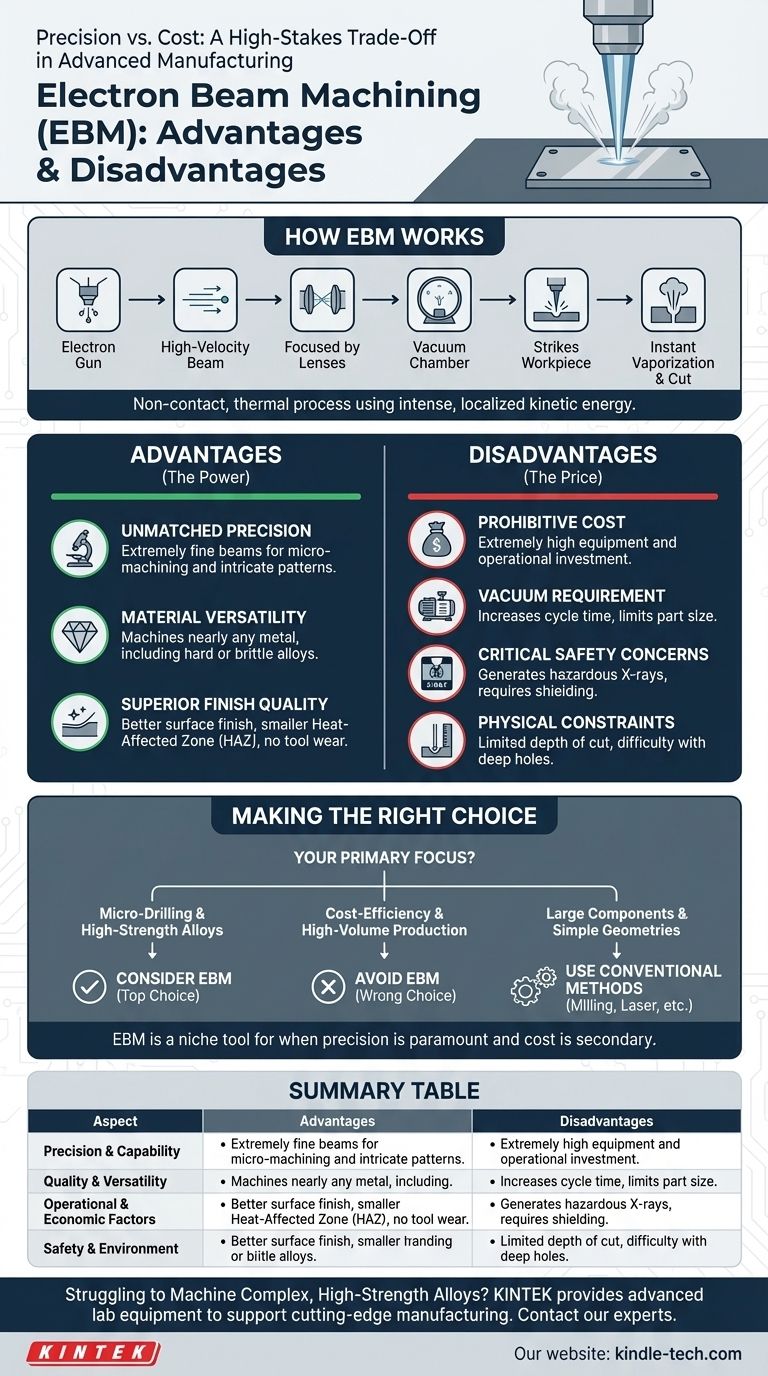

How Electron Beam Machining Works

Electron Beam Machining is a non-contact, thermal machining process. It operates on a principle of intense, localized heating.

The Core Mechanism

A stream of high-velocity electrons is generated and focused into an extremely narrow beam inside a vacuum chamber. This concentrated beam carries a massive amount of kinetic energy.

Material Vaporization

When this electron beam strikes the workpiece, the energy is instantly converted into heat. This heat is so intense that it vaporizes a small volume of the material, creating the desired cut or hole with no mechanical force.

The Key Advantages of EBM

The unique nature of EBM provides distinct benefits that are difficult to achieve with conventional or even other non-traditional machining methods.

Unmatched Precision and Detail

Because the electron beam is incredibly fine, EBM can produce extremely small holes and narrow cuts (kerfs). This makes it ideal for micro-machining applications and creating intricate patterns that are otherwise impossible.

Material Versatility

The process works by vaporization, not mechanical shearing. This means EBM is highly effective on a wide variety of metals and alloys, including those that are extremely hard, brittle, or difficult to machine conventionally.

Superior Finish Quality

Compared to other thermal cutting processes like plasma or laser cutting, EBM often produces a better surface finish with a smaller heat-affected zone (HAZ). This reduces the need for secondary finishing operations.

Understanding the Trade-offs and Limitations

The power and precision of EBM come with significant operational and financial challenges that restrict its use.

Prohibitive Cost

The equipment required for EBM—including the electron gun, high-voltage power supply, and vacuum chamber—is extremely expensive. This high capital investment limits its use to high-value components where no other process will suffice.

The Vacuum Requirement

The entire process must occur in a vacuum to prevent the electrons from scattering off air molecules. This requirement creates two major limitations: it significantly increases the cycle time for each part and restricts the size of the workpiece to what can fit inside the chamber.

Critical Safety Concerns

The interaction of the high-energy electron beam with the workpiece generates harmful X-rays. This necessitates substantial lead shielding and strict safety protocols to protect operators, adding to the system's cost and complexity.

Physical Constraints

EBM has a limited effective depth of cut. As the hole or cut deepens, it becomes more difficult for the vaporized material to escape, which can disrupt the beam's effectiveness and accuracy.

Making the Right Choice for Your Application

Selecting EBM is a strategic decision driven by the specific demands of the component, not a general-purpose choice.

- If your primary focus is micro-drilling or cutting complex patterns in high-strength alloys: EBM is one of the few processes capable of meeting these demanding requirements and should be a top consideration.

- If your primary focus is cost-efficiency or high-volume production: EBM is almost certainly the wrong choice due to its high operational costs and slow cycle times.

- If your primary focus is machining large components or simple geometries: More conventional and cost-effective methods like milling, turning, or laser cutting are far more suitable.

Ultimately, Electron Beam Machining is a powerful but niche tool, reserved for solving manufacturing challenges where precision is paramount and cost is a secondary concern.

Summary Table:

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Precision & Capability | Unmatched precision for micro-machining; can machine extremely hard/brittle materials | Limited depth of cut; complex geometries can be challenging |

| Quality & Versatility | Superior surface finish; small heat-affected zone (HAZ); works on any conductive material | Process is limited to electrically conductive materials only |

| Operational & Economic Factors | Non-contact process (no tool wear) | Extremely high equipment and operational costs; requires a vacuum chamber (limits part size/speed) |

| Safety & Environment | - | Generates hazardous X-rays; requires significant shielding and safety protocols |

Struggling to Machine Complex, High-Strength Alloys?

KINTEK specializes in providing advanced lab equipment and consumables to support cutting-edge manufacturing processes. If your project demands the extreme precision and material versatility of technologies like Electron Beam Machining, our experts can help you identify the right solutions for your R&D and quality control needs.

Contact KINTALK today to discuss how our equipment can enhance your laboratory's capabilities and help you tackle your most challenging material processing tasks.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Anti-Cracking Press Mold for Lab Use

- High Energy Vibratory Ball Mill for Lab Use

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High Energy Vibratory Laboratory Ball Mill Grinding Mill Single Tank Type

People Also Ask

- What is the hot filament chemical vapour deposition of diamond? A Guide to Synthetic Diamond Coating

- How is diamond coating made? A Guide to CVD and PVD Methods

- How do CVD diamonds grow? A Step-by-Step Guide to Lab-Grown Diamond Creation

- What is the process of coating deposition? A Step-by-Step Guide to Thin Film Engineering

- What is direct current DC magnetron sputtering? A Guide to High-Quality Thin Film Deposition