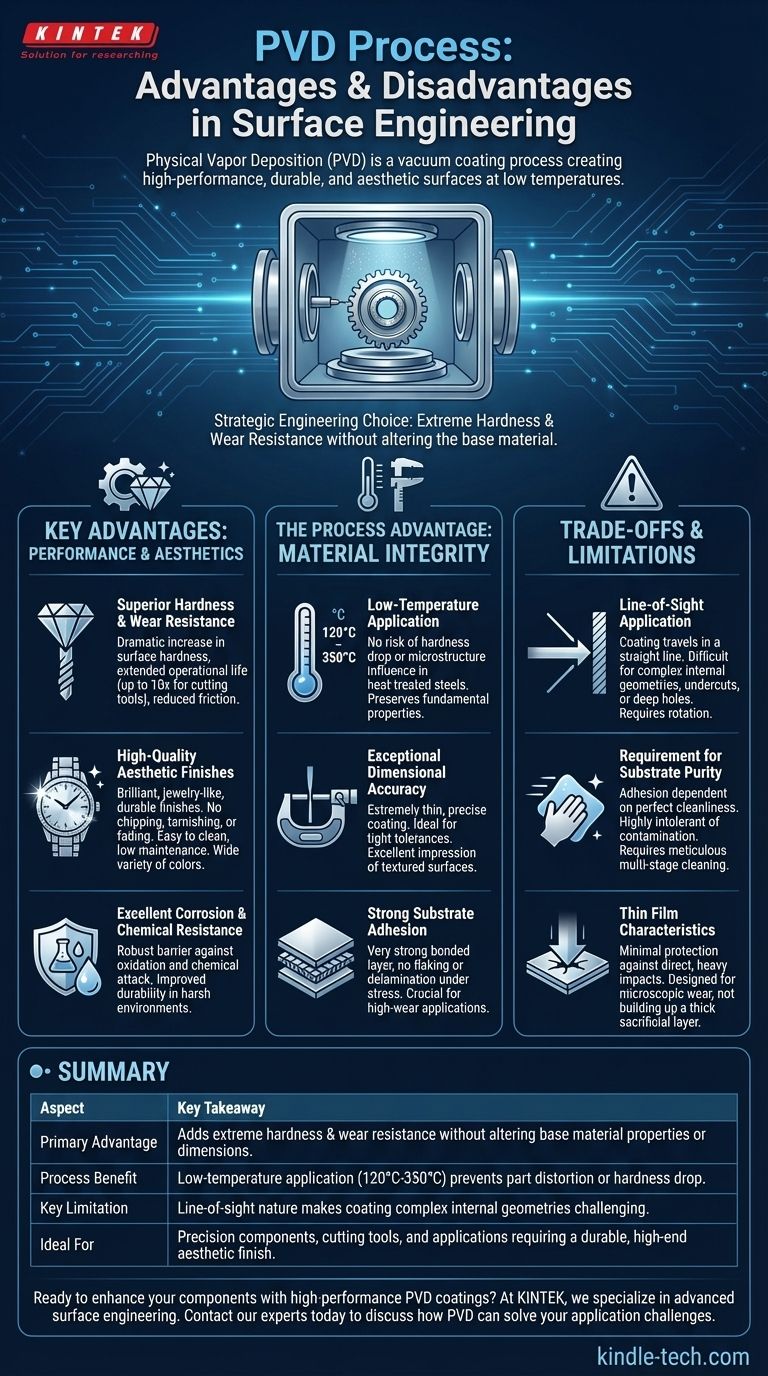

Physical Vapor Deposition (PVD) is a vacuum coating process that provides significant advantages in performance, durability, and aesthetics. Its core benefits include creating an extremely hard, wear-resistant surface and offering a variety of high-end finishes, all accomplished at low temperatures that do not damage or distort the underlying part.

PVD is not just a simple coating; it's a strategic engineering choice. Its primary value lies in adding high-performance surface properties like extreme hardness and wear resistance to a component without altering the underlying material's structure or dimensions.

Key Advantages: Enhancing Performance and Aesthetics

The benefits of PVD coatings stem from their ability to fundamentally upgrade a material's surface characteristics. This makes them suitable for a wide range of applications, from industrial tooling to decorative hardware.

Superior Hardness and Wear Resistance

PVD coatings dramatically increase the surface hardness of a component. This results in exceptional resistance to wear and abrasion.

For applications like cutting tools, this translates directly into a longer operational life, sometimes by a factor of ten. The added lubricity also reduces friction during use.

High-Quality Aesthetic Finishes

The process can deposit a brilliant, jewelry-like finish that is highly durable. Unlike other methods, PVD coatings do not chip, tarnish, or fade over time.

This provides a long-lasting, premium appearance that is also easy to clean and requires no additional maintenance to maintain its look. A wide variety of colors and finishes are available.

Excellent Corrosion and Chemical Resistance

The deposited layer acts as a robust barrier, protecting the substrate from oxidation and chemical attack. This improves the durability and lifespan of parts exposed to harsh environments.

Versatile and Customizable Layers

The PVD process allows for highly controlled and complex layer structures. Engineers can specify monolayers, multilayers, or even nanostructures to achieve specific performance goals. It can also be combined with other friction-reducing layers for customized results.

The Process Advantage: Preserving Material Integrity

Beyond the qualities of the coating itself, the PVD process has inherent advantages that make it ideal for high-precision components.

Low-Temperature Application

PVD is a low-temperature process, typically operating between 120°C and 350°C. This is a critical advantage.

It means there is no risk of a hardness drop in heat-treated steels and no influence on the microstructure of the substrate material. The part's fundamental properties are preserved.

Exceptional Dimensional Accuracy

Because the coating is extremely thin and applied with high precision, it maintains the component's exact dimensions and contours.

This makes PVD an ideal choice for precision parts with tight tolerances, where even a minor change in dimension would be unacceptable. It also provides a very good impression of previously textured or polished surfaces.

Strong Substrate Adhesion

PVD coatings form a very strong, bonded layer with the substrate. This ensures the coating will not flake or delaminate, even under significant stress, which is crucial for high-wear applications.

Understanding the Trade-offs and Limitations

While powerful, PVD is not a universal solution. An objective evaluation requires understanding its inherent limitations.

Line-of-Sight Application

PVD is a "line-of-sight" process. The coating material travels in a straight line from the source to the target component within the vacuum chamber.

This makes it difficult to coat complex internal geometries, undercuts, or deep, narrow holes uniformly. Parts often need to be rotated on complex fixtures to ensure even coverage.

Requirement for Substrate Purity

The exceptional adhesion of PVD coatings is entirely dependent on a perfectly clean surface. The process is highly intolerant of any surface contamination.

This means components must undergo a meticulous, multi-stage cleaning process before entering the vacuum chamber, adding time and cost to the overall operation.

Thin Film Characteristics

The thinness of a PVD coating is an advantage for dimensional accuracy, but it can be a limitation. It provides minimal protection against direct, heavy impacts that could deform the substrate underneath.

It is designed for resistance to microscopic wear and abrasion, not for building up a thick, sacrificial layer.

Making the Right Choice for Your Application

Selecting the right surface treatment depends entirely on your primary goal. PVD excels where surface performance is paramount and dimensional integrity must be preserved.

- If your primary focus is extending the life of cutting tools or high-wear components: PVD is an exceptional choice for its ability to add hardness and lubricity without compromising the tool's base material.

- If your primary focus is a durable, high-end decorative finish: PVD provides a tarnish-proof, fade-resistant surface in various colors that far outlasts traditional plating or painting.

- If your primary focus is protecting precision components with tight tolerances: The low-temperature process and thin-film nature of PVD make it ideal for coating parts without causing warping or dimensional changes.

Ultimately, selecting PVD is a decision to invest in superior surface engineering for applications where performance cannot be compromised.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Primary Advantage | Adds extreme hardness & wear resistance without altering the base material's properties or dimensions. |

| Process Benefit | Low-temperature application (120°C-350°C) prevents part distortion or hardness drop. |

| Key Limitation | Line-of-sight nature makes coating complex internal geometries challenging. |

| Ideal For | Precision components, cutting tools, and applications requiring a durable, high-end aesthetic finish. |

Ready to enhance your components with high-performance PVD coatings?

At KINTEK, we specialize in advanced lab equipment and consumables for surface engineering. Our expertise can help you leverage PVD technology to achieve superior wear resistance, brilliant finishes, and extended part life—all while preserving the integrity of your precision components.

Contact our experts today to discuss how PVD can solve your specific application challenges.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications