In short, Physical Vapor Deposition (PVD) is a process that yields exceptionally hard, thin, and durable coatings, but it is not a universally perfect solution. PVD excels at enhancing a product's wear resistance, corrosion resistance, and aesthetic appeal through a highly controlled vacuum deposition method. Its primary disadvantages, however, are not in the coating's performance but stem from the process itself, including its line-of-sight application and the critical need for pristine substrate preparation.

The decision to use PVD coating hinges on a trade-off: you gain exceptional surface performance and aesthetics on complex parts without altering their dimensions, but you must accept a process that requires meticulous preparation and is limited to surfaces it can directly "see."

The Functional Advantages: Enhancing Performance

PVD coatings are chosen when the surface of a component needs to outperform the bulk material it is made from. These functional benefits are the primary driver for its adoption in demanding technical applications.

Superior Hardness and Wear Resistance

PVD coatings are exceptionally hard and wear-resistant. This makes them ideal for applications like cutting tools, where they can increase tool life by as much as ten times.

The coating acts as a durable barrier, providing high resistance to the microscopic wear and abrasion that degrade components over time.

Improved Chemical and Corrosion Resistance

By depositing a dense, bonded layer onto a substrate, PVD provides an effective barrier against oxidation and chemical attack.

This improves the corrosion resistance of the underlying part, extending its operational life in moderately corrosive environments.

Reduced Friction

PVD coatings can be engineered to be extremely smooth and lubricious, which significantly reduces the coefficient of friction on a component's surface.

This is critical for moving parts, improving efficiency and preventing seizure under load.

Excellent Adhesion and Dimensional Stability

A key advantage of PVD is its excellent adhesion to the substrate. The process forms a strong, bonded interface between the coating and the part.

Furthermore, because PVD is a low-temperature process (typically 120°C-350°C), it does not affect the microstructure or temper of the base material. This, combined with the coating's thinness, ensures the dimensional accuracy of precision components is maintained.

The Aesthetic and Finishing Advantages

Beyond pure performance, PVD is a premier process for achieving high-quality decorative finishes that are as durable as they are beautiful.

High-Quality, Lasting Appearance

PVD provides a brilliant, decorative finish that can be produced in a wide variety of colors. This jewelry-like appearance is highly sought after for consumer products.

Crucially, this finish is not a simple layer of paint; it is a bonded part of the surface that does not chip, tarnish, or fade, ensuring it maintains its look over time without extra maintenance.

Perfect Replication of Surface Texture

The PVD process deposits a very thin, uniform layer that perfectly conforms to the substrate's existing finish.

This means it provides a very good impression of textured and polished surfaces, preserving the intended design and feel of the part while adding color and durability.

Understanding the Trade-offs and Limitations

No process is without its constraints. Acknowledging the limitations of PVD is essential for making an informed decision. These are not failures of the coating, but inherent aspects of the process.

Line-of-Sight Deposition

PVD is fundamentally a line-of-sight process. Think of it like spray painting, but with atoms; if the source material cannot "see" a surface, it cannot coat it.

This makes it difficult to coat the inside of long, narrow bores or complex internal geometries. These areas will receive little to no coating, creating a point of potential failure.

Requirement for Extreme Substrate Cleanliness

The process takes place in a high vacuum, and the adhesion of the coating is entirely dependent on a perfectly clean surface.

Any contamination from oils, dust, or even fingerprints can ruin the coating's adhesion. This means parts require rigorous, multi-stage cleaning and handling protocols, which adds complexity and cost to manufacturing.

Relatively Thin Film Thickness

PVD coatings are extremely thin, typically measured in single-digit microns (μm). While very hard, they provide minimal protection against heavy impacts or deep gouges.

For applications requiring significant material buildup for part restoration or resistance to heavy, abrasive wear, other processes like thermal spray or weld cladding are more appropriate.

Making the Right Choice for Your Application

To determine if PVD is the correct choice, you must weigh its powerful performance benefits against its process constraints.

- If your primary focus is extreme durability for precision tools: PVD is an exceptional choice, as its hardness and lubricity dramatically increase tool life without altering critical dimensions.

- If your primary focus is a premium, long-lasting decorative finish: PVD provides a superior aesthetic that resists fading and wear, making it ideal for high-end consumer products, fixtures, and jewelry.

- If your primary focus is coating internal, complex geometries: You should investigate alternative processes like Chemical Vapor Deposition (CVD), which is not line-of-sight and can better coat complex shapes.

- If your primary focus is low-cost, bulk corrosion protection: Simpler methods like galvanizing or painting may be more cost-effective, as the high-performance benefits of PVD might be unnecessary.

Understanding these core principles allows you to leverage PVD not just as a coating, but as a strategic tool for product enhancement.

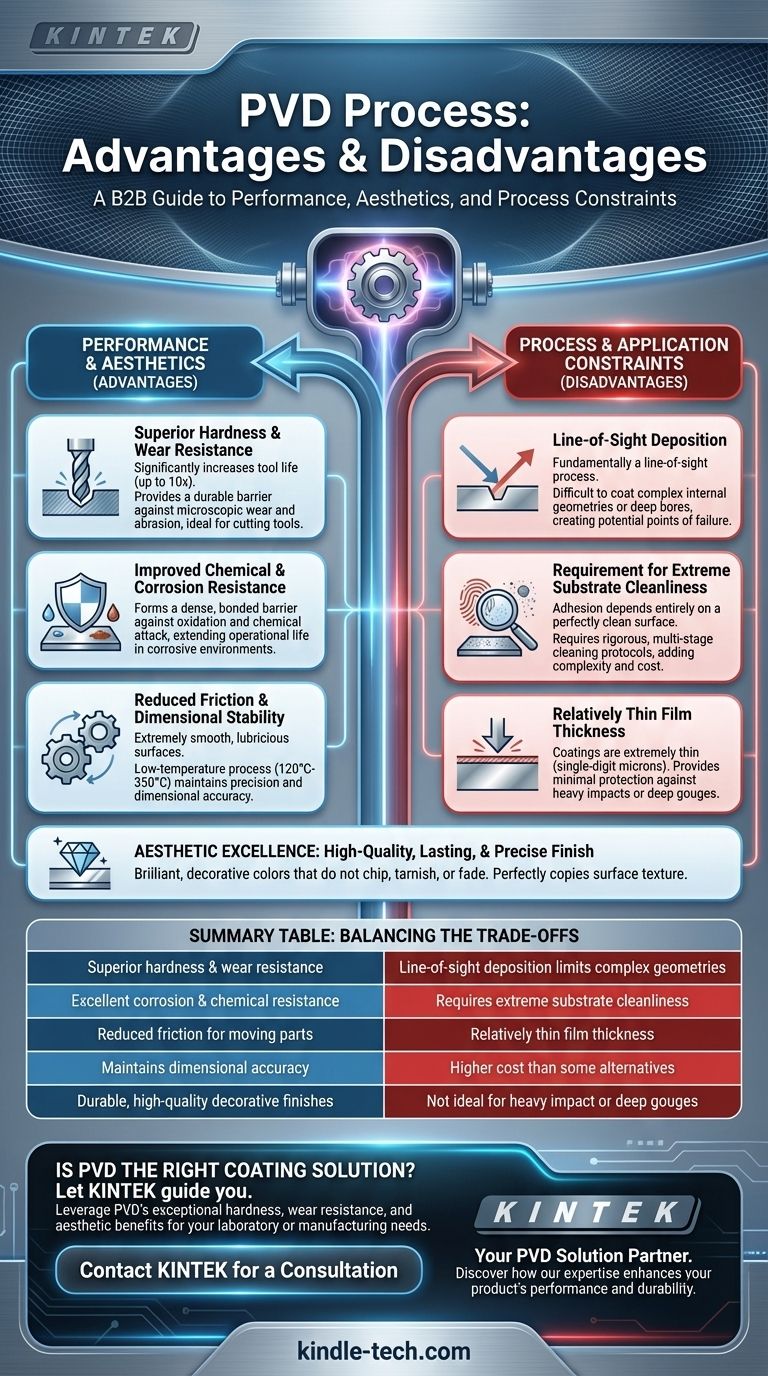

Summary Table:

| Advantage | Disadvantage |

|---|---|

| Superior hardness & wear resistance | Line-of-sight deposition limits complex geometries |

| Excellent corrosion & chemical resistance | Requires extreme substrate cleanliness |

| Reduced friction for moving parts | Relatively thin film thickness |

| Maintains dimensional accuracy | Higher cost than some alternatives |

| Durable, high-quality decorative finishes | Not ideal for heavy impact or deep gouges |

Is PVD the right coating solution for your precision tools or components?

At KINTEK, we specialize in advanced lab equipment and consumables, including PVD coating systems. Our expertise can help you leverage PVD's exceptional hardness, wear resistance, and aesthetic benefits for your laboratory or manufacturing needs.

Let our team guide you to the optimal surface enhancement solution. Contact KINTEK today for a consultation and discover how our PVD expertise can enhance your product's performance and durability.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications