In short, a planetary ball mill excels at creating extremely fine powders with high speed and precision. Its primary advantages stem from the immense energy generated by its unique planetary motion, allowing it to efficiently grind even the hardest materials within a sealed, contamination-free environment. This makes it ideal for a vast range of applications, from advanced materials research to pharmaceutical preparation.

A planetary ball mill's true value lies in its combination of power and control. By superimposing the rotation of the grinding jars with a larger, counter-rotating sun wheel, it generates forces far exceeding those of a conventional ball mill, enabling rapid, reproducible, and ultra-fine grinding for demanding laboratory applications.

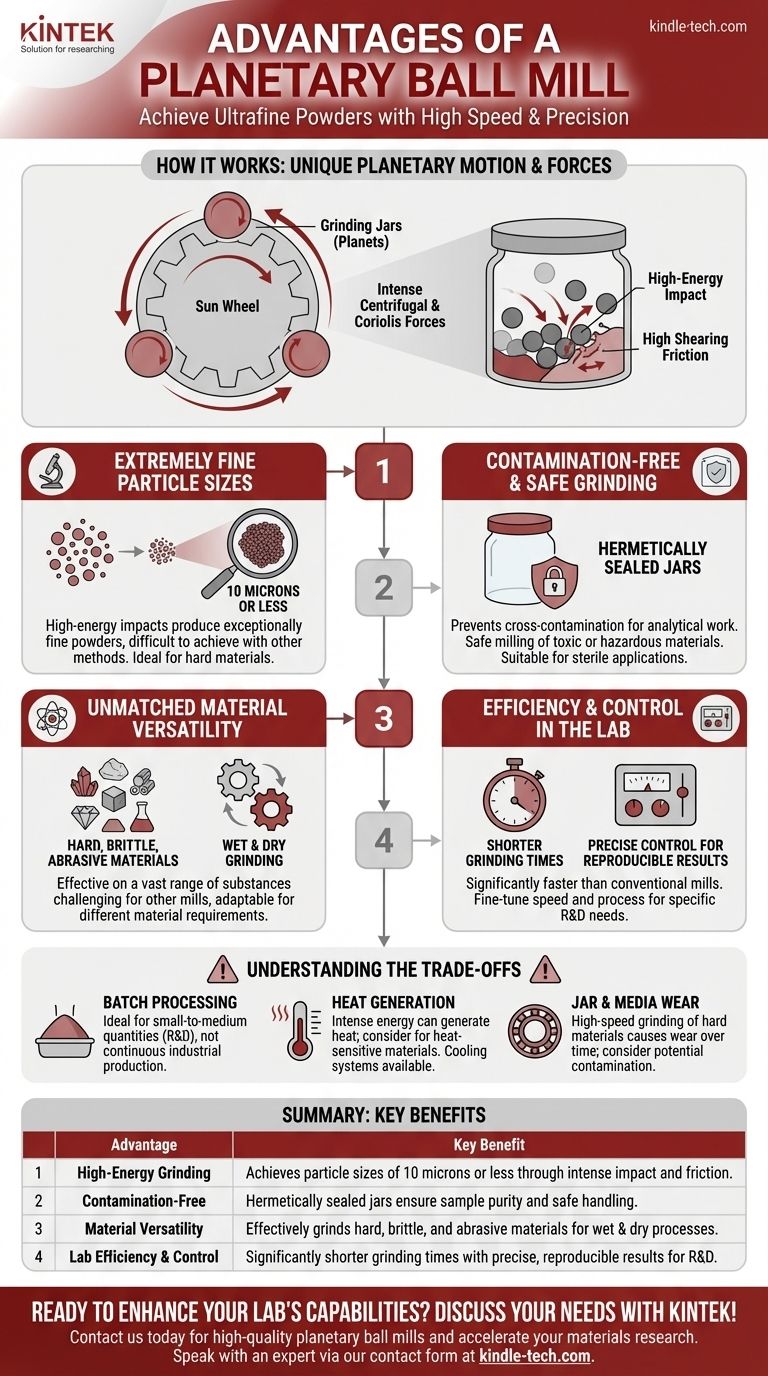

How a Planetary Ball Mill Achieves Its Power

To understand the advantages, you must first understand the mechanism. It's a simple concept that produces powerful results.

The Unique Planetary Motion

A planetary ball mill features one or more grinding jars, which act as "planets," mounted on a rotating disc known as the "sun wheel." Crucially, the sun wheel rotates in one direction while the grinding jars rotate on their own axes in the opposite direction.

This counter-rotation is the key. It creates a powerful interplay of centrifugal and Coriolis forces, causing the grinding balls inside the jars to move chaotically and with tremendous acceleration.

High-Energy Impact and Friction

The grinding balls are flung against the inner walls of the jar at high speeds, pulverizing the sample material through intense impact forces.

Simultaneously, the constant movement and friction between the balls and between the balls and the jar wall create high shearing forces. This combination of impact and friction is what leads to extremely effective and rapid particle size reduction.

The Core Advantages Explained

The unique mechanics of a planetary ball mill translate directly into several key operational benefits.

Achieving Extremely Fine Particle Sizes

The high-energy impacts allow planetary ball mills to produce exceptionally fine powders, often reaching particle sizes of 10 microns or less. This level of fineness is difficult to achieve with many other grinding methods, especially for hard materials.

Contamination-Free and Safe Grinding

The entire grinding process occurs within hermetically sealed jars. This enclosed system is critical for two reasons. First, it prevents cross-contamination of the sample, which is essential for analytical work. Second, it allows for the safe milling of toxic or hazardous materials without exposing the operator.

This also makes it suitable for sterile applications, such as preparing ophthalmic and parenteral products in the pharmaceutical industry.

Unmatched Material Versatility

Planetary ball mills are effective on a vast range of materials, including hard, brittle, and abrasive substances that are challenging for other mills. They are used for chemicals, minerals, ceramics, alloys, and more.

Furthermore, they are adaptable to both wet and dry grinding processes, adding to their flexibility for different material requirements.

Efficiency and Control in the Lab

The high energy input results in significantly shorter grinding times compared to conventional ball mills. This makes them highly efficient for laboratory work, especially when preparing small quantities of materials for research and analysis.

The rotational speeds of the sun wheel and jars can also be precisely controlled, allowing users to fine-tune the grinding process to achieve specific, reproducible results.

Understanding the Trade-offs

While powerful, the planetary ball mill is not a universal solution. Understanding its limitations is key to using it effectively.

Primarily for Batch Processing

Due to the use of sealed jars, planetary ball mills are inherently batch-based systems. They are ideal for preparing small-to-medium quantities of material, which is perfect for R&D, but not for large-scale, continuous industrial production.

Heat Generation

The intense energy and friction within the jars can generate significant heat. This can be a problem for heat-sensitive materials, potentially altering their chemical or physical properties. Some advanced models offer cooling systems to mitigate this.

Jar and Media Wear

Grinding hard or abrasive materials at high speeds inevitably causes wear on the grinding jars and balls. Over time, this can introduce minute contamination from the grinding media itself into the sample, a factor that must be considered for high-purity applications.

Making the Right Choice for Your Goal

To determine if a planetary ball mill is the correct tool, consider your primary objective.

- If your primary focus is rapid R&D and material analysis: Its speed and effectiveness with small sample sizes make it the ideal choice for quickly preparing materials for testing.

- If your primary focus is preparing high-purity or sensitive materials: The sealed, contamination-free grinding environment is its most critical advantage.

- If your primary focus is milling hard, brittle, or abrasive substances: Its high-energy impact mechanism provides the power needed to reduce challenging materials to fine powders where other methods fail.

Ultimately, the planetary ball mill is the definitive laboratory tool for achieving fine particle sizes with speed, versatility, and control.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| High-Energy Grinding | Achieves particle sizes of 10 microns or less through intense impact and friction. |

| Contamination-Free Processing | Hermetically sealed jars ensure sample purity and safe handling of hazardous materials. |

| Material Versatility | Effectively grinds hard, brittle, and abrasive materials for both wet and dry processes. |

| Lab Efficiency & Control | Significantly shorter grinding times with precise, reproducible results for R&D. |

Ready to enhance your lab's capabilities with precise, high-energy grinding?

At KINTEK, we specialize in providing high-quality laboratory equipment, including planetary ball mills, to meet the demanding needs of research and development. Our solutions are designed to help you achieve ultrafine powders efficiently and reliably, ensuring contamination-free results for your most critical applications.

Contact us today to discuss how a KINTEK planetary ball mill can accelerate your materials research and deliver the precision you need. Get in touch via our contact form to speak with an expert!

Visual Guide

Related Products

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- Laboratory Planetary Ball Mill Cabinet Planetary Ball Milling Machine

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High Energy Planetary Ball Mill for Laboratory Horizontal Tank Type Milling Machine

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

People Also Ask

- What is the working principle of planetary ball mill? Unlock High-Energy Grinding for Nanoscale Results

- What are the parameters of a planetary ball mill? Master Speed, Time, and Media for Perfect Grinding

- What is the difference between a ball mill and a planetary ball mill? Unlock the Right Grinding Technology for Your Lab

- What is the principle of planetary ball mill? Achieve Rapid, High-Energy Grinding for Your Materials

- What size are planetary mill particles? Achieve Nanoscale Precision for Your Materials