The primary advantages of Chemical Vapor Deposition (CVD) for synthesizing nanomaterials are its exceptional control over the final product's properties, its ability to produce materials of very high purity and quality, and its versatility in depositing a wide range of substances onto complex surfaces. This makes it one of the most effective and commonly employed techniques for creating advanced nanomaterials like graphene and high-performance thin films.

At its core, Chemical Vapor Deposition should be understood not just as a coating method, but as a precision engineering tool at the atomic and molecular level. It provides the control necessary to build nanomaterials from the ground up with specific, predictable, and superior properties.

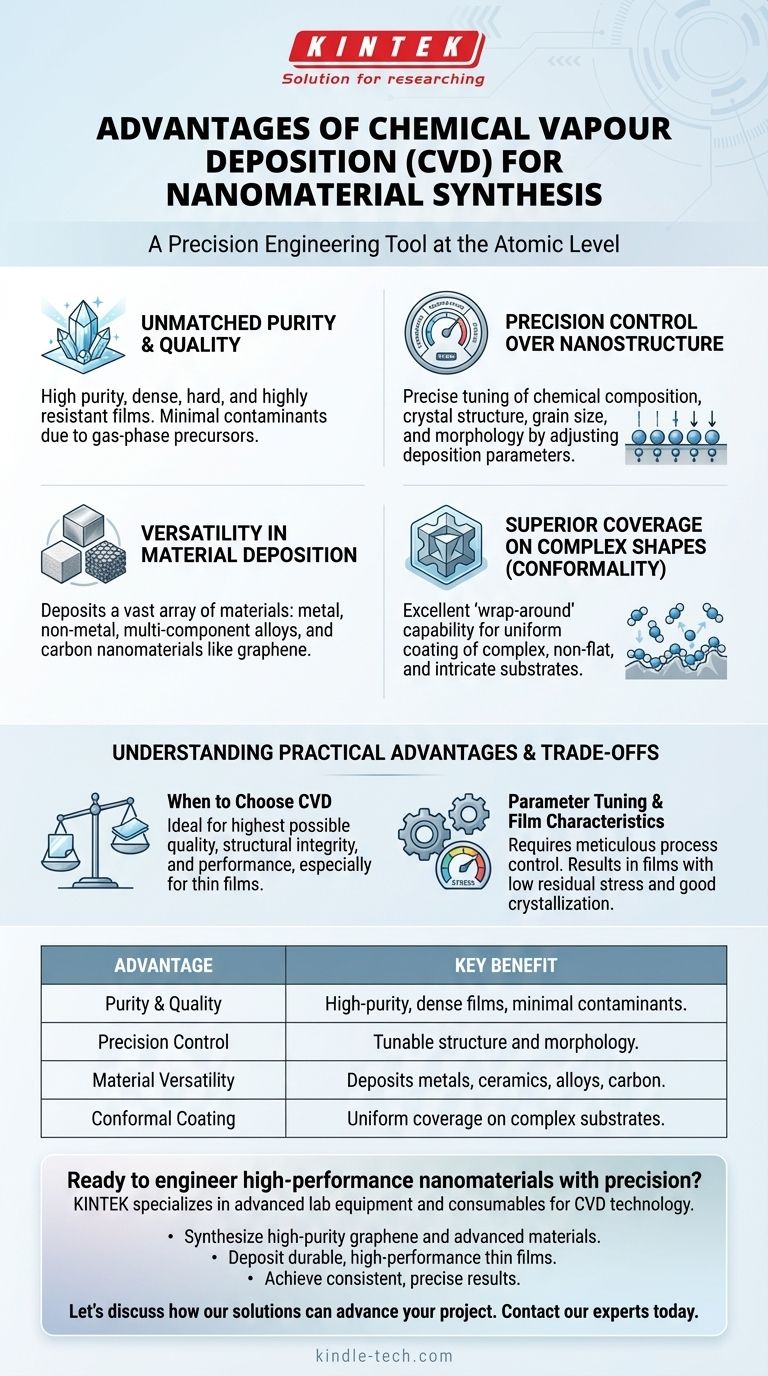

Why CVD Excels in Nanomaterial Synthesis

Chemical Vapor Deposition is a process where a substrate is exposed to one or more volatile precursors, which react or decompose on the substrate surface to produce the desired deposit. This bottom-up approach is what gives it a distinct advantage in the nanoscale domain.

Unmatched Purity and Quality

The process inherently produces materials with very high purity because the precursors are introduced as gases, minimizing contaminants common in wet-chemical methods.

This results in films that are dense, hard, and highly resistant to damage. The controlled deposition environment ensures a superior final product.

Precision Control Over Nanostructure

CVD offers unparalleled control over the final material by carefully adjusting key deposition parameters like temperature, pressure, and gas flow rates.

This allows for the precise tuning of the material's chemical composition, crystal structure, grain size, and morphology, which are the very factors that define a nanomaterial's function.

Versatility in Material Deposition

The technique is not limited to a narrow class of substances. It can be used to deposit a vast array of materials.

This includes metal films, non-metal films, multi-component alloys, and complex ceramic or compound layers. Its use in synthesizing carbon nanomaterials, including graphene, is particularly notable.

Superior Coverage on Complex Shapes

One of the standout features of CVD is its excellent "wrap-around" capability, also known as conformality.

Because the deposition occurs from a gas phase, the process can uniformly coat complex, non-flat, and intricately shaped substrates, which is a significant challenge for many other deposition techniques.

Understanding the Practical Advantages and Trade-offs

While the quality of the output is paramount, the practical aspects of CVD also contribute to its widespread adoption. However, it's crucial to understand where it fits in the landscape of nanomaterial synthesis.

When to Choose CVD Over Other Methods

Traditional techniques like hydrothermal and sol-gel methods are effective for certain applications. However, CVD is the preferred choice when the primary goal is the highest possible quality and structural control.

While other methods may be simpler for bulk powder synthesis, CVD excels in creating high-performance thin films and coatings where purity and structural integrity are non-negotiable.

The Importance of Parameter Tuning

The significant advantages of CVD are not automatic. They are a direct result of meticulous process control.

Achieving the desired outcome requires expertise in tuning the deposition parameters. This trade-off between control and complexity is central to the CVD process.

Favorable Film Characteristics

The resulting films often exhibit low residual stress and good crystallization. These are critical properties for ensuring the stability and performance of the material in its final application, especially in electronics and optics.

Making the Right Choice for Your Goal

Selecting a synthesis method depends entirely on the intended application and the required properties of the nanomaterial.

- If your primary focus is the highest material purity and performance: CVD is the ideal choice for creating dense, highly pure, and crystalline films with superior hardness and resistance.

- If your primary focus is precise structural engineering at the nanoscale: CVD offers unparalleled control over morphology, grain size, and composition simply by adjusting process parameters.

- If your primary focus is coating complex or 3D substrates: The excellent conformal coverage of CVD ensures a uniform and high-quality deposition on even the most intricate surfaces.

Ultimately, Chemical Vapor Deposition is a foundational technique that transforms gaseous precursors into high-value, precisely engineered solid materials.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Purity & Quality | High-purity, dense, and hard films with minimal contaminants. |

| Precision Control | Tunable chemical composition, crystal structure, and morphology. |

| Material Versatility | Deposits metals, ceramics, alloys, and carbon nanomaterials like graphene. |

| Conformal Coating | Uniform coverage on complex, 3D, and non-flat substrates. |

Ready to engineer high-performance nanomaterials with precision?

Chemical Vapor Deposition (CVD) is the key to achieving superior material purity, exact structural control, and uniform coatings on complex components. At KINTEK, we specialize in providing advanced lab equipment and consumables tailored to your specific research and production needs.

Our expertise in CVD technology can help you:

- Synthesize high-purity graphene and other advanced nanomaterials.

- Deposit durable, high-performance thin films for electronics and optics.

- Achieve consistent, repeatable results with precise process control.

Let's discuss how our solutions can advance your project. Contact our experts today for a personalized consultation.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What is a CVD tube furnace? A Complete Guide to Thin-Film Deposition

- What is the floating catalyst method? A Guide to High-Yield CNT Production

- What are the advantages of industrial CVD for solid boriding? Superior Process Control and Material Integrity

- Why are carbon nanotubes important in industry? Unlocking Next-Generation Material Performance

- What function does CVD equipment serve in rhodium-modified coatings? Achieve Deep Diffusion and Microstructural Precision