The fundamental advantage of metal sintering is its ability to produce strong, dimensionally accurate, and complex metal parts in high volumes at a low per-unit cost. It achieves this by forming solid components from metal powder below the material's melting point, which minimizes material waste, reduces energy consumption, and allows for the creation of shapes that are difficult or impossible to achieve with traditional casting or machining.

Sintering is not just a cost-saving alternative; it is a transformative manufacturing process. It empowers engineers to design parts based on ideal function and form, rather than being constrained by the limitations of conventional subtractive or melting techniques.

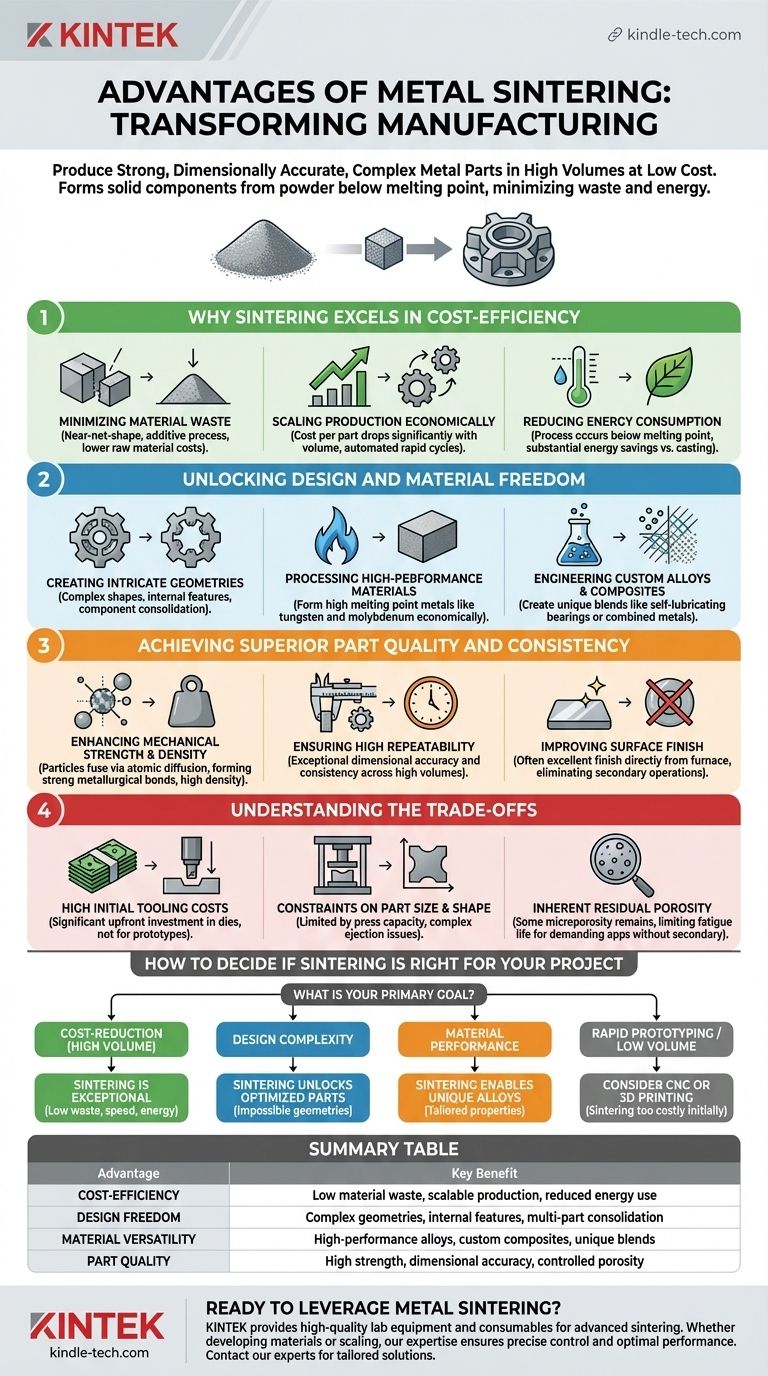

Why Sintering Excels in Cost-Efficiency

For many projects, the decision to use sintering comes down to its powerful economic advantages, especially as production volume increases.

Minimizing Material Waste

Traditional "subtractive" manufacturing, like CNC machining, starts with a solid block of metal and cuts away material to create the final shape. This process can generate significant, often costly, scrap material.

Sintering is an "additive" or near-net-shape process. It uses only the amount of powdered metal needed to form the part, dramatically reducing waste and lowering raw material costs.

Scaling Production Economically

While there is an initial investment in tooling and dies, the cost per part drops significantly as production volume increases.

The automated and highly repeatable nature of the process allows for rapid production cycles, making sintering far more cost-effective than machining for medium- to high-volume runs.

Reducing Energy Consumption

Sintering occurs at temperatures below the material's melting point.

Compared to casting, which requires fully melting the metal, this represents a substantial energy saving, contributing to both lower operational costs and a more environmentally friendly footprint.

Unlocking Design and Material Freedom

Sintering removes many of the barriers that limit part design in other manufacturing methods, allowing for a higher degree of innovation.

Creating Intricate Geometries

The process excels at producing parts with a high degree of complexity. This includes internal cavities, undercuts, and non-machinable features.

This allows for the consolidation of multiple components into a single, more robust sintered part, reducing assembly time and potential points of failure.

Processing High-Performance Materials

Materials with extremely high melting points, such as tungsten and molybdenum, are notoriously difficult and expensive to process via casting.

Sintering provides a more manageable and cost-effective method to form these high-performance materials into functional components.

Engineering Custom Alloys and Composites

The powder metallurgy process allows for the creation of unique material blends that are not possible through melting.

For example, graphite can be mixed in to create self-lubricating bearings, or different metals like copper and iron can be combined to achieve a specific balance of strength and thermal conductivity.

Achieving Superior Part Quality and Consistency

The highly controlled nature of the sintering process translates directly into reliable, high-quality components.

Enhancing Mechanical Strength and Density

During sintering, particles fuse together through atomic diffusion, creating strong metallurgical bonds known as sintered necks.

This process significantly reduces the porosity of the initial compacted powder, leading to a dense part with excellent mechanical strength and durability. Advanced techniques, like vacuum sintering, can further prevent oxidation and achieve even higher densities.

Ensuring High Repeatability

Because parts are formed in the same precise die, sintering delivers exceptional dimensional accuracy and consistency from the first part to the millionth. This high degree of tolerance control is critical for components used in complex assemblies.

Improving Surface Finish

Sintered parts can often achieve an excellent surface finish directly out of the furnace, potentially eliminating the need for secondary finishing operations like grinding or polishing, which saves time and cost.

Controlling Porosity by Design

While high density is often the goal, sintering offers the unique ability to intentionally control the level of porosity. This is essential for applications like filters, which require a specific flow rate, or for oil-impregnated bearings that rely on porosity to store lubricant.

Understanding the Trade-offs

No process is perfect. To make an informed decision, you must be aware of sintering's limitations.

High Initial Tooling Costs

The hardened steel dies and tooling required for pressing and shaping the powder represent a significant upfront investment. This makes sintering uneconomical for one-off prototypes or very low-volume production runs.

Constraints on Part Size and Shape

The size of the component is limited by the tonnage capacity of the compaction press. Furthermore, extremely complex shapes that prevent the part from being ejected from the die may not be suitable for conventional sintering.

Inherent Residual Porosity

While greatly reduced, some level of microporosity almost always remains in a sintered part unless secondary operations (like Hot Isostatic Pressing) are performed. For the most demanding applications where fatigue life is the absolute priority, this can be a limiting factor compared to a fully wrought or forged part.

How to Decide if Sintering is Right for Your Project

Your choice of manufacturing process should be driven by your primary goal.

- If your primary focus is cost-reduction at high volume: Sintering is an exceptional choice due to its low material waste, high-speed production, and reduced energy use.

- If your primary focus is design complexity: Sintering unlocks the ability to create optimized, lightweight, and multi-functional parts with geometries that are impossible to machine.

- If your primary focus is material performance: Sintering enables the use of unique alloys, composites, and high-melting-point metals to achieve tailored properties.

- If your primary focus is rapid prototyping or low-volume production: You should consider methods like CNC machining or metal 3D printing, as sintering's high initial tooling costs will not be economical.

Ultimately, choosing metal sintering is about enabling better design by removing the constraints of traditional manufacturing.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Cost-Efficiency | Low material waste, scalable production, reduced energy use |

| Design Freedom | Complex geometries, internal features, multi-part consolidation |

| Material Versatility | High-performance alloys, custom composites, unique blends |

| Part Quality | High strength, dimensional accuracy, controlled porosity |

Ready to leverage the power of metal sintering for your lab or production needs? KINTEK specializes in providing the high-quality lab equipment and consumables essential for advanced sintering processes. Whether you're developing new materials or scaling production, our expertise ensures you achieve precise temperature control, consistent results, and optimal part performance. Contact our experts today to discuss how we can support your sintering projects with reliable solutions tailored to your laboratory requirements.

Visual Guide

Related Products

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Spark Plasma Sintering Furnace SPS Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

People Also Ask

- What are the factors influencing shrinkage during sintering? Control Dimensional Changes for Precision Parts

- Why must green bodies produced via binder jetting undergo treatment in a vacuum sintering furnace?

- Why is a high vacuum environment necessary in sintering equipment for TiAl alloys? Ensure High-Purity Metal Bonding

- Why is a high vacuum required for sintering Ti-43Al-4Nb-1Mo-0.1B? Ensure Purity & Fracture Toughness

- Why is sintering easier in the presence of a liquid phase? Unlock Faster, Lower-Temperature Densification