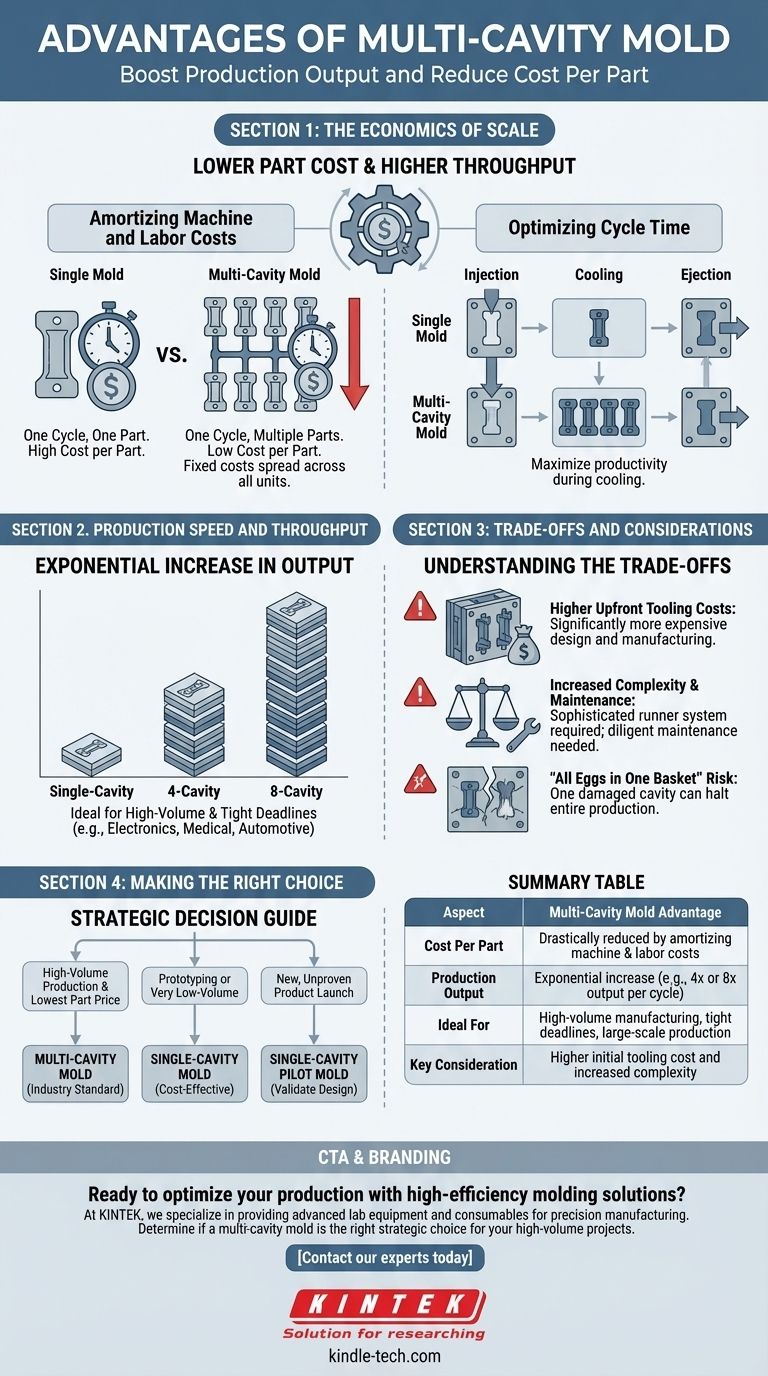

The primary advantages of a multi-cavity mold are a dramatic increase in production output and a significant reduction in the cost per part. By creating multiple components in a single injection molding cycle, you leverage the same machine, operator, and cycle time to produce more units, achieving powerful economies of scale.

A multi-cavity mold is an investment in efficiency. While the initial tooling cost is higher, it unlocks lower unit prices and higher throughput, making it the definitive choice for high-volume manufacturing.

The Economics of Scale: Why More Cavities Lower Part Cost

The most compelling reason to use a multi-cavity mold is its direct impact on the final price of each part. This cost reduction is not marginal; it is a fundamental shift in production economics.

Amortizing Machine and Labor Costs

A single injection molding cycle has fixed costs associated with it, primarily the machine's run time and the labor of the operator.

Whether a mold produces one part or eight parts, the machine still completes one cycle. A multi-cavity tool spreads these fixed costs across all the parts produced, drastically lowering the cost contribution to any single unit.

Optimizing Cycle Time

The total cycle time includes injection, cooling, and ejection. Cooling is often the longest phase.

A multi-cavity mold makes effective use of this entire period. While the parts are cooling, you are solidifying multiple units simultaneously instead of just one, maximizing the productivity of every second.

The Impact on Production Speed and Throughput

For projects with high demand or tight deadlines, production speed is paramount. Multi-cavity molds provide an exponential increase in output compared to their single-cavity counterparts.

Achieving High-Volume Output

A 4-cavity mold produces approximately four times the number of parts as a single-cavity mold in the same period, using only one machine. An 8-cavity mold produces eight times the parts.

This capability is essential for meeting the demands of consumer electronics, medical disposables, or automotive components where millions of units are required annually.

Meeting Tight Market Deadlines

For a new product launch, the ability to rapidly build inventory can be a significant competitive advantage. Multi-cavity molding allows you to scale from zero to hundreds of thousands of units in a fraction of the time, ensuring you can meet launch day demand.

Understanding the Trade-offs and Considerations

The benefits of multi-cavity molds are clear, but they are not the right solution for every project. Understanding the trade-offs is critical for making an informed decision.

Higher Upfront Tooling Costs

This is the most significant barrier. A multi-cavity mold is substantially more complex and expensive to design and manufacture than a single-cavity mold.

The cost does not scale linearly. A 4-cavity mold will cost significantly more than four single-cavity molds due to the complexity of the internal runner system required to feed all cavities.

Increased Tool Complexity and Maintenance

A multi-cavity mold requires a sophisticated runner system to distribute the molten plastic to each cavity evenly. Achieving a balanced fill—where all cavities fill at the same rate and pressure—is a complex engineering challenge.

Imbalances can lead to part defects like short shots or flash, and the tool itself requires more diligent maintenance to keep all cavities operating perfectly.

The "All Eggs in One Basket" Risk

If one cavity is damaged or requires maintenance, the entire mold may need to be taken out of production. This halts the output from all cavities, a risk not present when running multiple, independent single-cavity molds.

Making the Right Choice for Your Production Goals

Selecting the right cavity count is a strategic decision that balances your project's volume, budget, and timeline.

- If your primary focus is high-volume production and the lowest possible part price: A multi-cavity mold is the industry standard once your projected volume justifies the initial tooling investment.

- If your primary focus is prototyping or very low-volume production: A single-cavity mold is the most cost-effective and practical choice due to its minimal upfront cost.

- If your primary focus is launching a new, unproven product: A common strategy is to begin with a single-cavity pilot mold to validate the design before committing to a high-cost, multi-cavity production tool.

Ultimately, choosing the right cavity count is a strategic decision that balances upfront investment against long-term manufacturing efficiency.

Summary Table:

| Aspect | Multi-Cavity Mold Advantage |

|---|---|

| Cost Per Part | Drastically reduced by amortizing machine & labor costs across multiple units |

| Production Output | Exponential increase (e.g., 4x or 8x output per cycle) |

| Ideal For | High-volume manufacturing, tight deadlines, large-scale production |

| Key Consideration | Higher initial tooling cost and increased complexity |

Ready to optimize your production with high-efficiency molding solutions?

At KINTEK, we specialize in providing advanced lab equipment and consumables, including solutions for precision manufacturing. Our expertise can help you determine if a multi-cavity mold is the right strategic choice to boost your output and reduce your costs for high-volume projects.

Contact our experts today to discuss your specific needs and discover how we can bring efficiency and scale to your laboratory or production line.

Visual Guide

Related Products

- Special Shape Press Mold for Lab

- Polygon Press Mold for Lab

- Cylindrical Press Mold with Scale for Lab

- Round Bidirectional Press Mold for Lab

- Ball Press Mold for Lab

People Also Ask

- What is the function of press molds during the preparation of SiCf/Ti-43Al-9V composites? Achieve Structural Precision

- How do graphite molds and hydraulic presses work together? Perfect Your FeCrAl Pre-Forming Today!

- What is the core function of high-strength graphite molds? Master Vacuum Hot Press Sintering Efficiency

- What are the primary functions of high-purity graphite molds in YAG ceramic sintering? Enhance Material Purity & Density

- What functions do high-strength molds serve in nanocopper hot pressing? Achieve Maximum Density and Plastic Flow

- How does compression molding affect the environment? A Guide to Sustainable Manufacturing

- What are the considerations for Mould design? Optimize for Quality, Speed, and Cost

- How much does it cost to make a mold? A Strategic Guide to Injection Mold Pricing