At its core, Physical Vapor Deposition (PVD) is favored for its exceptional ability to apply high-performance, ultra-thin coatings with immense precision onto a vast range of materials. The process works in a vacuum, physically transferring a coating material from a solid source to a substrate, which results in films that are extremely pure, dense, and durable.

The true advantage of PVD lies in its nature as a lower-temperature, physical process. This unlocks the ability to coat temperature-sensitive materials and produce exceptionally high-purity functional coatings that are often impossible to achieve with chemical-based methods.

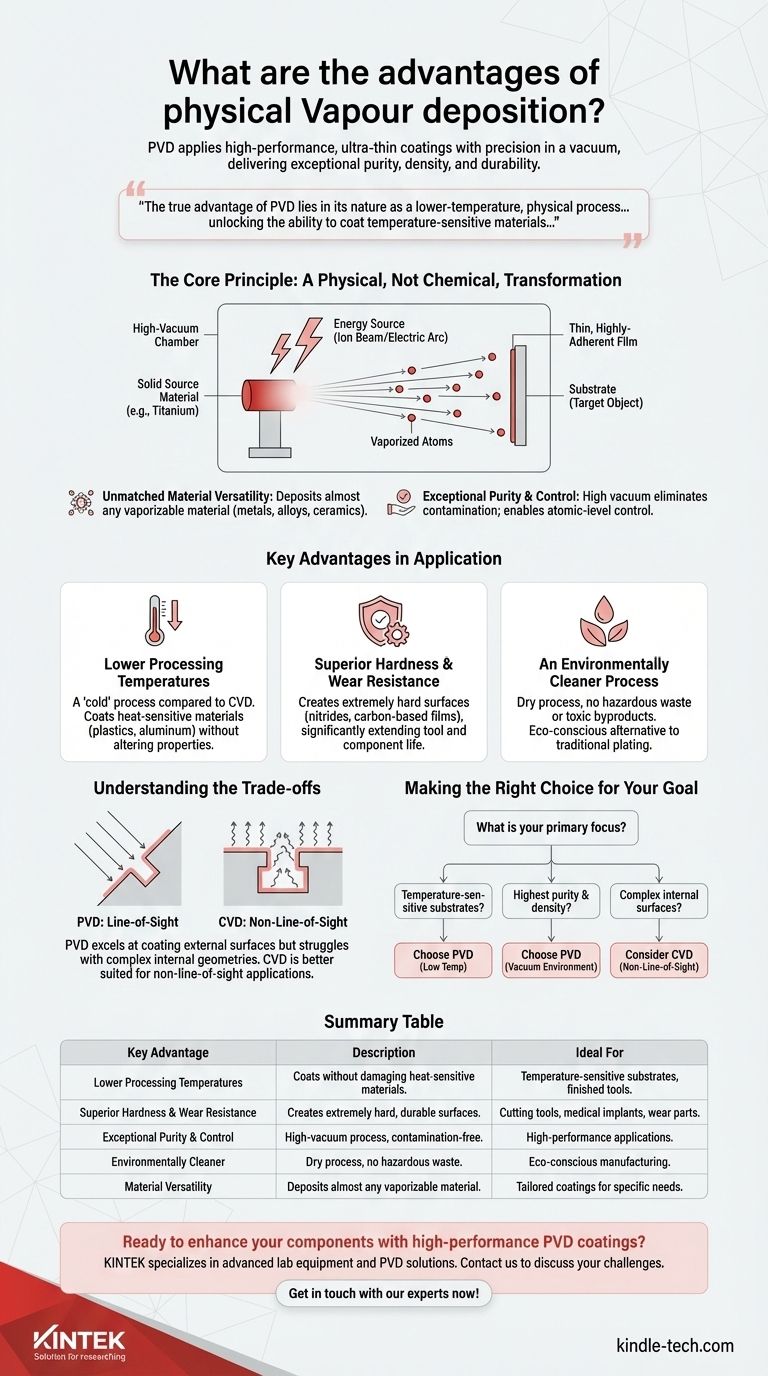

The Core Principle: A Physical, Not Chemical, Transformation

To understand PVD's advantages, you must first understand its fundamental mechanism. Unlike processes that rely on chemical reactions, PVD is a purely physical phenomenon.

How PVD Works (Simplified)

In a high-vacuum chamber, a solid source material (like titanium or chromium) is bombarded with energy. This energy, often from an ion beam or an electric arc, vaporizes atoms from the source.

These vaporized atoms then travel in a straight line through the vacuum and deposit onto the target object, building a thin, highly-adherent film one atom at a time.

Unmatched Material Versatility

Because PVD is not dependent on chemical reactions, it can be used to deposit almost any material that can be vaporized.

This includes metals, alloys, ceramics, and other inorganic compounds. This versatility allows for the creation of coatings tailored for specific properties like hardness, lubricity, or electrical conductivity.

Exceptional Purity and Control

The entire PVD process occurs in a high vacuum, which eliminates the possibility of contamination from atmospheric gases.

This results in coatings of extremely high purity. Furthermore, because the deposition is a direct physical transfer, operators have precise, atomic-level control over the coating's thickness and structure.

Key Advantages in Application

The physical nature of the PVD process translates into several critical real-world benefits that set it apart from other coating methods.

Lower Processing Temperatures

PVD is fundamentally a "cold" process compared to its main alternative, Chemical Vapor Deposition (CVD), which often requires very high temperatures to initiate the necessary chemical reactions.

This lower-temperature operation is a decisive advantage, as it allows for coating materials that cannot withstand high heat, such as plastics, aluminum alloys, and heat-treated steels, without altering their fundamental properties.

Superior Hardness and Wear Resistance

PVD coatings, particularly nitrides and carbon-based films, are known for their extreme hardness, often exceeding that of the underlying substrate material by a significant margin.

This creates a highly durable surface that provides excellent resistance to abrasion, erosion, and corrosion, dramatically extending the life of tools, components, and medical implants.

An Environmentally Cleaner Process

PVD is a dry, environmentally friendly process. It produces no hazardous waste materials or chemical byproducts that require special disposal.

This stands in stark contrast to traditional plating and many CVD processes, which often involve toxic precursor chemicals and produce harmful effluents.

Understanding the Trade-offs

No technology is perfect for every application. To make an informed decision, it's crucial to understand PVD's primary limitation, especially when compared to CVD.

The "Line-of-Sight" Limitation

The physical particles vaporized in a PVD process travel in a straight line from the source to the substrate.

This means PVD is a line-of-sight process. It excels at coating external surfaces but struggles to uniformly coat complex internal geometries, undercuts, or the inside of narrow tubes. In contrast, the gas-based nature of CVD makes it a non-line-of-sight process, which is far better suited for these complex shapes.

Deposition Rates

While efficient for thin films (typically under 5 microns), PVD can have slower deposition rates compared to some high-speed CVD processes, especially when very thick coatings are required.

Making the Right Choice for Your Goal

Selecting the right coating technology depends entirely on the specific requirements of your component and its application.

- If your primary focus is coating temperature-sensitive substrates like plastics or finished steel tools: PVD is the superior choice due to its low processing temperature.

- If your primary focus is achieving the highest purity and density for a performance-critical surface: PVD's vacuum environment gives it a distinct advantage.

- If your primary focus is coating the internal surfaces of a complex part: You must consider a non-line-of-sight process like Chemical Vapor Deposition (CVD).

Ultimately, your decision must be guided by the unique geometry, material, and desired performance characteristics of your specific application.

Summary Table:

| Key Advantage | Description | Ideal For |

|---|---|---|

| Lower Processing Temperatures | Coats without damaging heat-sensitive materials like plastics and aluminum. | Temperature-sensitive substrates, finished tools. |

| Superior Hardness & Wear Resistance | Creates extremely hard, durable surfaces that resist abrasion and corrosion. | Cutting tools, medical implants, wear parts. |

| Exceptional Purity & Control | High-vacuum process ensures contamination-free, precisely controlled coatings. | High-performance applications requiring precise film properties. |

| Environmentally Cleaner | Dry process with no hazardous chemical waste or byproducts. | Eco-conscious manufacturing, replacing traditional plating. |

| Material Versatility | Can deposit almost any vaporizable material (metals, ceramics, alloys). | Tailored coatings for specific hardness, lubricity, or conductivity needs. |

Ready to enhance your components with high-performance PVD coatings?

At KINTEK, we specialize in advanced lab equipment and consumables, including PVD solutions tailored to your laboratory's specific needs. Our expertise ensures you achieve the durable, pure, and precise coatings required for superior performance in tools, medical devices, and critical components.

Contact us today to discuss how our PVD technology can solve your coating challenges and bring unmatched value to your applications.

Get in touch with our experts now!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What are the advantages of plasma enhanced CVD? Enable Low-Temperature, High-Quality Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition