In powder metallurgy, sintering is the critical transformative step that turns a compacted powder into a strong, functional component. Its primary advantages are the ability to create complex, near-net-shape parts with minimal material waste, achieve high production repeatability, and effectively process materials that are difficult or impossible to melt and cast. This makes it an exceptionally efficient and versatile manufacturing process.

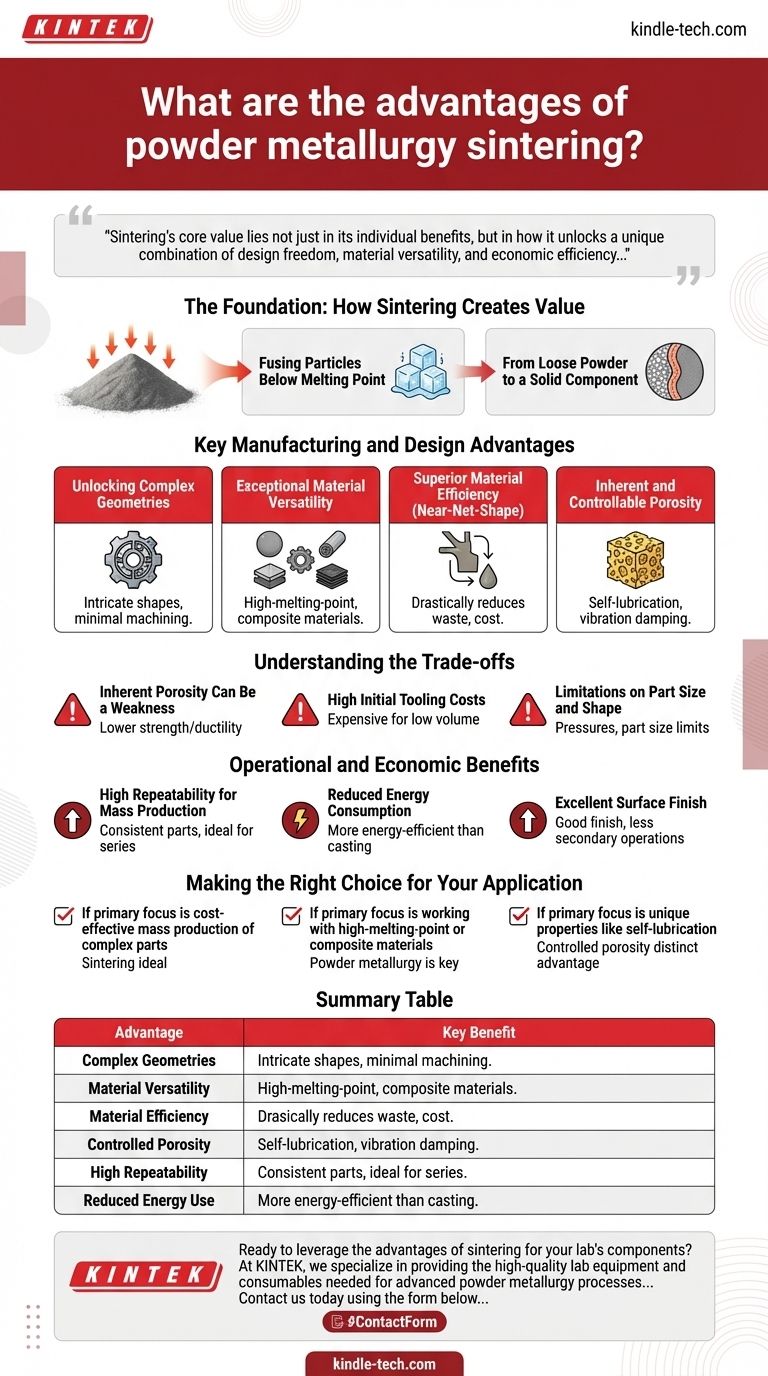

Sintering's core value lies not just in its individual benefits, but in how it unlocks a unique combination of design freedom, material versatility, and economic efficiency that is often unattainable with traditional machining or casting methods.

The Foundation: How Sintering Creates Value

Sintering is a heat treatment that provides the strength and integrity for the final part. Understanding this mechanism is key to appreciating its advantages.

Fusing Particles Below Melting Point

The process involves heating a compacted powder component to a temperature below the material's melting point. At this elevated temperature, the atoms at the contact points between powder particles diffuse, creating strong metallurgical bonds.

Think of it like ice cubes in a glass of water. Even below the melting point of water, the cubes will fuse together at their contact surfaces over time. Sintering accelerates this solid-state fusion for metal particles.

From Loose Powder to a Solid Component

This atomic bonding process eliminates much of the void space between particles, increasing the part's density, strength, hardness, and structural integrity. The result is a solid component ready for use or final finishing.

Key Manufacturing and Design Advantages

The nature of the sintering process provides several distinct advantages for engineers and designers.

Unlocking Complex Geometries

Sintering excels at producing parts with very complex external and internal shapes. Because the initial shape is formed by pressing powder in a precision die, features that would be difficult or expensive to machine can be incorporated directly into the part.

Exceptional Material Versatility

Powder metallurgy is often the best—or only—method for creating components from certain materials. This includes refractory metals with extremely high melting points (e.g., tungsten) and composite materials made from elements that don't mix when melted.

Superior Material Efficiency (Near-Net-Shape)

The process is considered "near-net-shape" because the initial compacted part is very close to the final dimensions. This drastically reduces material waste compared to subtractive processes like machining, where significant material is cut away. This saves both raw material costs and production time.

Inherent and Controllable Porosity

Unlike fully dense materials made by melting, sintered parts retain a certain level of porosity. This can be a unique advantage. The pores can be impregnated with oil for self-lubricating bearings or used to create filters. This porosity also gives sintered parts excellent vibration-dampening characteristics.

Understanding the Trade-offs

No process is perfect. To use sintering effectively, it is critical to understand its limitations.

Inherent Porosity Can Be a Weakness

The same porosity that provides benefits can also be a drawback. Sintered parts typically have lower ultimate tensile strength and ductility compared to their wrought or forged counterparts. For applications requiring maximum strength, this can be a limiting factor.

High Initial Tooling Costs

The dies and molds required to compact the powder are made to extremely high tolerances and are therefore expensive. This makes powder metallurgy most cost-effective for medium-to-high volume production runs where the tooling cost can be amortized over many parts.

Limitations on Part Size and Shape

While excellent for complexity, there are limits. Extremely large parts can be difficult to produce due to the immense pressures required for compaction. Certain features, like undercuts or holes perpendicular to the pressing direction, can also be challenging or impossible to form directly.

Operational and Economic Benefits

Beyond design, sintering delivers significant value on the production floor.

High Repeatability for Mass Production

Once the tooling is created, the powder metallurgy process can produce tens of thousands of identical parts with exceptional dimensional consistency. This makes it ideal for large production series, such as in the automotive industry.

Reduced Energy Consumption

Because the material is never fully melted, the sintering process consumes significantly less energy than casting. This results in lower production costs and makes it a more environmentally sustainable ("green") technology.

Excellent Surface Finish

Sintered parts typically have a good surface finish straight out of the furnace, often reducing or eliminating the need for secondary finishing operations. This further saves time and cost in the manufacturing workflow.

Making the Right Choice for Your Application

Selecting the right manufacturing process depends entirely on your project's specific goals.

- If your primary focus is cost-effective mass production of complex parts: Sintering is ideal due to its high repeatability and near-net-shape process, which minimizes waste and machining time over large volumes.

- If your primary focus is working with high-melting-point or composite materials: Powder metallurgy is often the only viable method for creating net-shape components from materials that cannot be effectively cast or machined.

- If your primary focus is unique properties like self-lubrication or vibration damping: The controlled porosity of sintered parts is a distinct advantage that cannot be easily replicated by other manufacturing methods.

By understanding these core advantages and trade-offs, you can confidently determine when sintering is the optimal choice for your manufacturing needs.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Complex Geometries | Creates intricate shapes difficult with machining/casting |

| Material Versatility | Processes high-melting-point metals & composites |

| Material Efficiency | Near-net-shape process minimizes waste |

| Controlled Porosity | Enables self-lubrication & vibration damping |

| High Repeatability | Ideal for cost-effective mass production |

| Reduced Energy Use | Lower energy than melting processes like casting |

Ready to leverage the advantages of sintering for your lab's components?

At KINTEK, we specialize in providing the high-quality lab equipment and consumables needed for advanced powder metallurgy processes. Whether you are developing new materials or optimizing production, our solutions help you achieve superior results with efficiency and precision.

Contact us today using the form below to discuss how we can support your laboratory's specific needs. Let's turn your complex part designs into reality.

Visual Guide

Related Products

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

- 1200℃ Muffle Furnace Oven for Laboratory

- Horizontal High Temperature Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Furnace Bottom Discharge Graphitization Furnace for Carbon Materials

People Also Ask

- What temperature should a furnace run at? From Home Comfort to Industrial Processes

- What is the deposition of thin film using sputtering method? A Guide to High-Purity Film Coating

- How do the 3 types of thermal treatment differ? Master Annealing, Normalizing, and Hardening

- What are the variables in the sintering process? Master Temperature, Time & Atmosphere for Perfect Results

- Is it economically viable to recycle plastic? The Harsh Economic Reality of Plastic Recycling

- Is biomass conversion environmentally friendly? It Depends on Your Feedstock and Technology

- What is the process of sputtering in a vacuum? A Guide to High-Purity Thin Film Deposition

- How does a constant temperature shaking incubator support bioleaching for waste PCBs? Optimize Your Metal Recovery