At its core, a rotary furnace is advantageous because it simultaneously heats and mixes materials within a precisely controlled atmosphere. This unique capability results in superior temperature uniformity, highly efficient gas exchange, and consistent product quality, making it ideal for processing powders, granules, and other bulk solids.

The fundamental advantage of a rotary furnace is not simply its ability to heat, but its creation of a dynamic processing environment. By continuously tumbling the material, it exposes the entire surface area to heat and atmosphere, solving the common problems of non-uniformity and inefficiency inherent in static furnace designs.

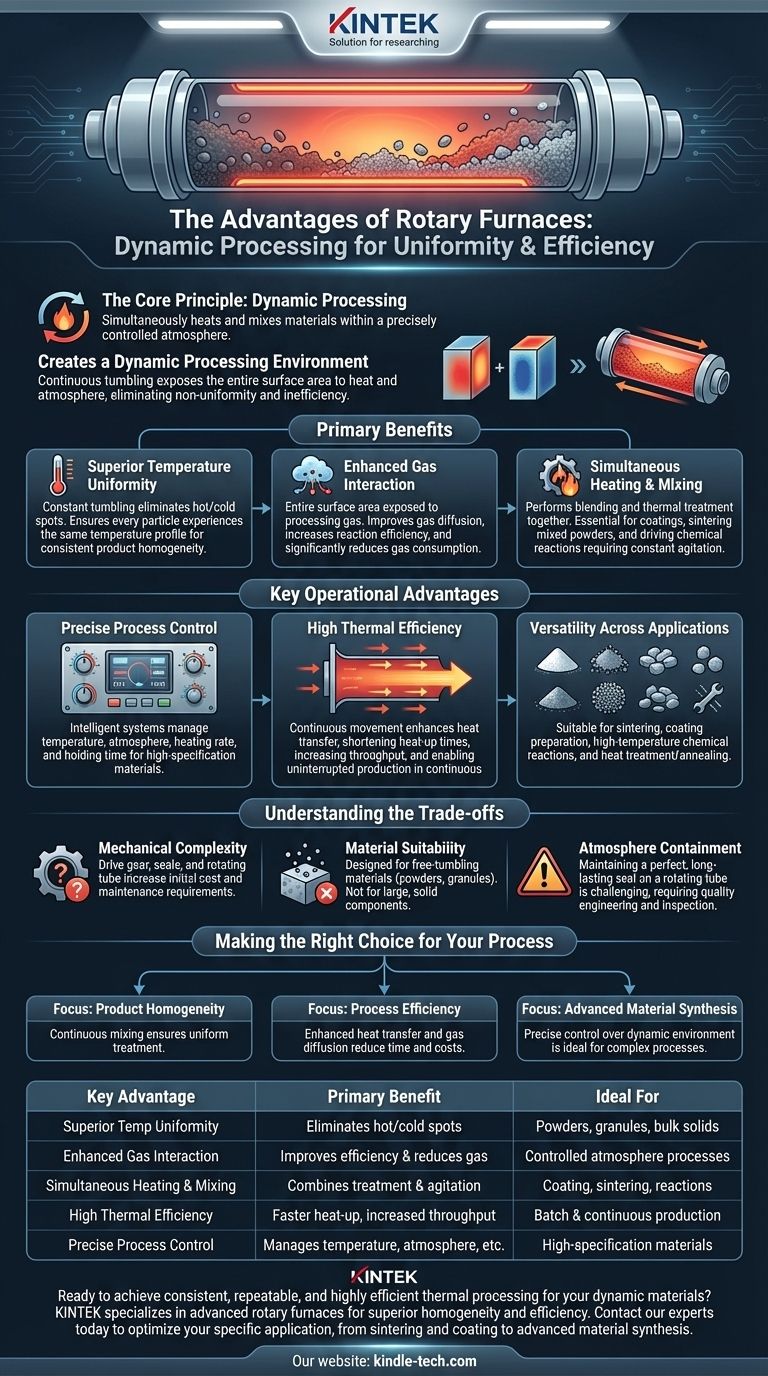

The Core Principle: Dynamic Processing

The primary benefits of a rotary furnace stem from its most defining feature: the rotation of the processing tube. This continuous movement fundamentally changes how the material interacts with its environment.

Superior Temperature Uniformity

In a static furnace, material at the edges of a batch heats faster than material in the center. The constant tumbling action in a rotary furnace eliminates these hot and cold spots.

This ensures every particle experiences the same temperature profile, leading to exceptional product homogeneity and consistent results from batch to batch.

Enhanced Gas Interaction

When treating materials in a specific atmosphere (such as a reducing or inert gas), the rotation is a significant advantage.

It ensures the entire surface area of the material is exposed to the processing gas. This improves gas diffusion, increases the efficiency of chemical reactions, and can significantly reduce overall gas consumption compared to static methods.

Simultaneous Heating and Mixing

The furnace's design allows it to perform two critical functions at once. This dual action is essential for applications where blending and thermal treatment must occur in unison.

This capability is especially valuable for creating coatings, sintering mixed powders, or driving chemical reactions that require constant agitation to proceed evenly.

Key Operational Advantages

Beyond the core principle of dynamic processing, rotary furnaces offer several practical benefits that make them a preferred choice for many industrial and laboratory applications.

Precise Process Control

Modern rotary furnaces are equipped with intelligent control systems. These allow for the precise management of critical variables like temperature, atmosphere, heating rate, and holding time.

This level of control is crucial for producing high-specification materials, such as those used in batteries or advanced ceramics, where minor deviations can compromise performance.

High Thermal Efficiency

The continuous movement of the material enhances heat transfer. This allows the furnace to bring a batch of material up to temperature in a shorter period, increasing throughput and overall process efficiency.

For continuous models, material passes through the heated zone, maintaining a consistent temperature and enabling uninterrupted production.

Versatility Across Applications

Rotary furnaces are not limited to a single function. Their unique capabilities make them suitable for a wide range of thermal processes.

Common uses include the sintering of metal and ceramic powders, the preparation of coatings, driving high-temperature chemical reactions, and the heat treatment and annealing of metals.

Understanding the Trade-offs

While highly effective, the design of a rotary furnace presents a few considerations that distinguish it from simpler, static systems. Objectively weighing these is key to making an informed decision.

Mechanical Complexity

The inclusion of a drive gear, seals, and a rotating tube introduces more mechanical complexity than a standard box or tube furnace. This can translate to higher initial costs and specific maintenance requirements for the drive system.

Material Suitability

These furnaces are specifically designed for materials that can tumble freely, such as powders, granules, and small parts. They are not suitable for large, solid components or materials that could be damaged by the tumbling action.

Atmosphere Containment

While highly effective at creating controlled atmospheres, maintaining a perfect, long-lasting seal on a rotating tube can be more challenging than on a static one. This requires quality engineering and regular inspection of the seals.

Making the Right Choice for Your Process

Ultimately, the decision to use a rotary furnace depends entirely on the requirements of your material and the goals of your process.

- If your primary focus is product homogeneity: The continuous mixing action of a rotary furnace is the most effective way to ensure every particle in a batch receives uniform treatment.

- If your primary focus is process efficiency: The enhanced heat transfer and superior gas diffusion significantly reduce processing times and lower the consumption of expensive gases.

- If your primary focus is advanced material synthesis: The precise control over a dynamic environment is ideal for complex processes like sintering, catalyst preparation, and coating applications.

Choosing a rotary furnace is an investment in achieving consistent, repeatable, and highly efficient thermal processing for dynamic materials.

Summary Table:

| Key Advantage | Primary Benefit | Ideal For |

|---|---|---|

| Superior Temperature Uniformity | Eliminates hot/cold spots for consistent product quality | Powders, granules, bulk solids |

| Enhanced Gas Interaction | Improves reaction efficiency & reduces gas consumption | Processes requiring controlled atmospheres |

| Simultaneous Heating & Mixing | Combines thermal treatment with constant agitation | Coating, sintering, chemical reactions |

| High Thermal Efficiency | Faster heat-up times and increased throughput | Batch and continuous production |

| Precise Process Control | Manages temperature, atmosphere, and heating rates | High-specification materials (e.g., batteries, ceramics) |

Ready to achieve consistent, repeatable, and highly efficient thermal processing for your dynamic materials?

KINTEK specializes in advanced laboratory equipment, including rotary furnaces designed for superior homogeneity and efficiency when processing powders, granules, and other bulk solids. Our solutions offer precise control over temperature and atmosphere, helping you enhance product quality and reduce operational costs.

Contact our experts today to discuss how a KINTEK rotary furnace can optimize your specific application, from sintering and coating to advanced material synthesis.

Visual Guide

Related Products

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- How are composites processed using sintering? Engineered Material Solutions Through Advanced Thermal Bonding

- What is the function of a high-temperature furnace during burnout? Master Aluminum Foam Production with Precision

- How do tube furnaces or muffle furnaces ensure stoichiometric accuracy during synthesis? Mastering Li4GeO4 & Li4VO4

- What is a rotary retort furnace? Achieve Superior Uniformity in Continuous Heat Treatment

- How are tube furnaces classified based on the orientation of the tube? Choose the Right Design for Your Process