At its core, sintering offers the ability to create strong, complex metal parts without melting the material. The primary advantages lie in achieving enhanced material properties, enabling the mass production of intricate geometries, and providing a highly cost-effective and repeatable manufacturing process, especially for high-volume applications.

Sintering is more than a manufacturing technique; it's a process of material transformation. By heating compacted metal powder below its melting point, you fundamentally re-engineer its internal structure to create a dense, strong component with properties often superior to the base material.

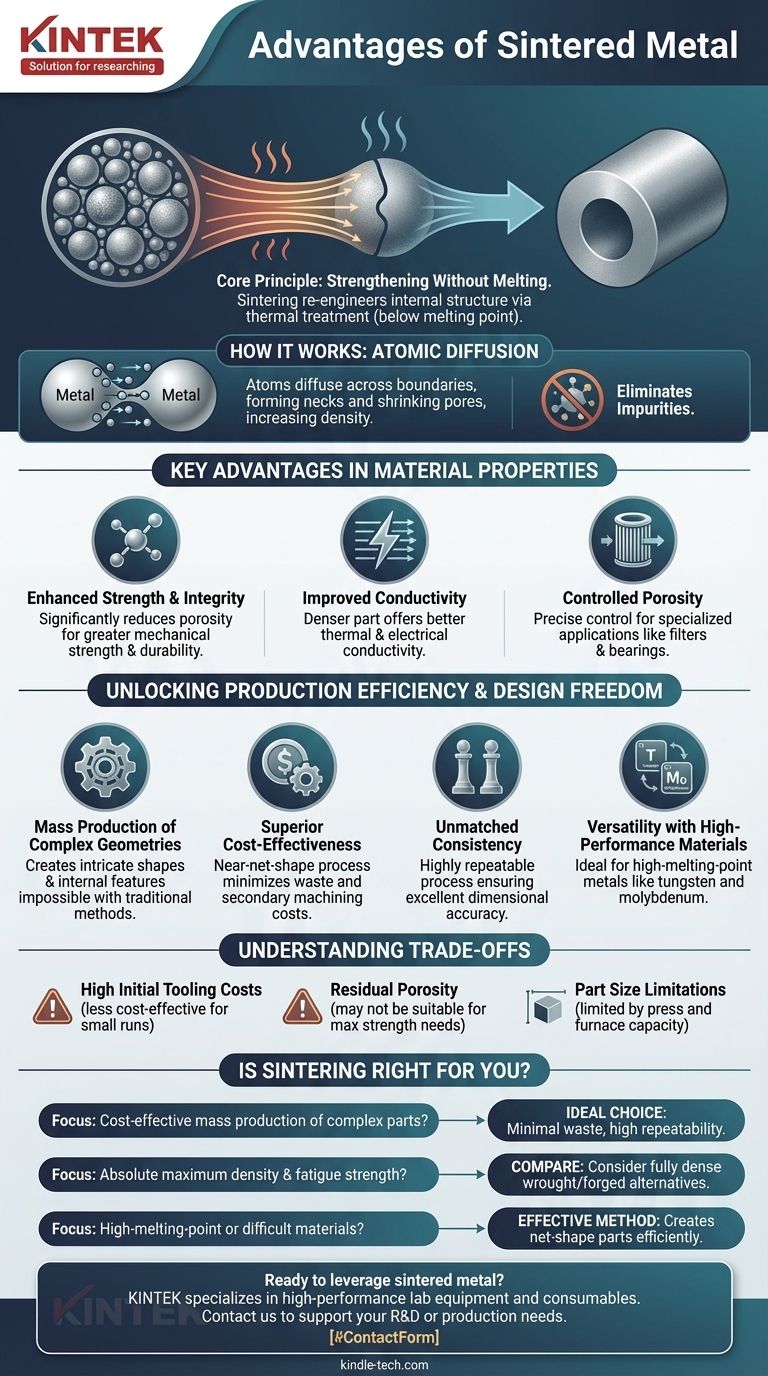

The Core Principle: Strengthening Without Melting

Sintering is a thermal treatment applied to a compacted powder. The goal is to create a coherent, solid mass without liquefying the material.

How It Works: Atomic Diffusion

The process works by heating the material to a temperature where the atoms in the metal particles become mobile enough to diffuse across the boundaries of adjacent particles.

This atomic diffusion creates "necks" or bridges between the particles. As these necks grow, the pores between the particles shrink, and the overall part becomes denser and stronger.

Eliminating Impurities

The high-temperature environment also serves to burn off contaminants, such as lubricants used in the initial compaction stage, and reduce surface oxides on the powder particles. This results in a cleaner, more robust final part.

Key Advantages in Material Properties

Sintering directly enhances the physical and mechanical characteristics of the final component.

Enhanced Strength and Integrity

By significantly reducing porosity—the empty space between the original powder particles—sintering creates a denser, more solid structure. This directly translates to greater mechanical strength, integrity, and durability.

Improved Conductivity

A denser part with strong bonds between particles provides a clearer path for energy to travel. This results in improved thermal and electrical conductivity compared to the initial, unconsolidated powder.

Controlled Porosity for Specialized Applications

While the usual goal is to reduce porosity, the process allows for precise control over it. For applications like filters or self-lubricating bearings, a specific level of interconnected porosity can be intentionally maintained.

Unlocking Production Efficiency and Design Freedom

Beyond material science, sintering provides significant advantages for manufacturing and design.

Mass Production of Complex Geometries

Sintering excels at producing parts with intricate shapes, internal channels, or features that are difficult, expensive, or impossible to create using traditional machining or casting.

Superior Cost-Effectiveness at Scale

The process is near-net-shape, meaning the initial part is formed very close to its final dimensions. This dramatically reduces material waste and minimizes the need for costly secondary machining, making it highly economical for medium-to-high volume production runs.

Unmatched Consistency and Precision

Sintering is a highly repeatable process that delivers excellent dimensional accuracy and tolerance control from part to part. This consistency is critical for automated assembly and high-performance applications.

Versatility with High-Performance Materials

The process is uniquely suited for materials with extremely high melting points, such as tungsten and molybdenum. Sintering allows these materials to be formed into solid parts without the immense energy and technical challenges associated with melting them.

Understanding the Trade-offs

No process is universally superior. It is critical to understand the limitations of sintering to make an informed decision.

High Initial Tooling Costs

The dies and tooling required to compact the powder can be expensive. This makes sintering less cost-effective for very small production runs or one-off prototypes.

Residual Porosity

While sintering dramatically reduces porosity, it may not eliminate it entirely. For the most demanding applications requiring the absolute highest strength and fatigue resistance, fully dense materials made through forging or machining from bar stock may still have an edge.

Part Size Limitations

The size of a sintered part is constrained by the capacity of the compaction press and the size of the sintering furnace. This typically limits the process to small- and medium-sized components.

Is Sintering the Right Choice for Your Project?

Use these guidelines to determine if sintering aligns with your primary goal.

- If your primary focus is cost-effective mass production of complex parts: Sintering is an ideal choice, offering minimal waste and high repeatability for intricate designs.

- If your primary focus is achieving the absolute maximum material density and fatigue strength: You should carefully compare the properties of a sintered component against a fully dense wrought or forged alternative.

- If your primary focus is working with high-melting-point or difficult-to-machine materials: Sintering is one of the most effective and efficient methods available to create net-shape parts.

By leveraging controlled heat to bond particles, sintering empowers you to build superior components from the ground up.

Summary Table:

| Key Advantage | Description |

|---|---|

| Enhanced Material Properties | Creates stronger, denser parts with improved thermal/electrical conductivity. |

| Design Freedom | Enables mass production of intricate shapes and internal features. |

| Cost-Effectiveness | Near-net-shape process minimizes material waste and secondary machining. |

| High Repeatability | Delivers excellent dimensional accuracy and consistency for volume production. |

| Material Versatility | Ideal for high-melting-point metals like tungsten and molybdenum. |

Ready to leverage the power of sintered metal for your components?

At KINTEK, we specialize in providing the high-performance lab equipment and consumables necessary for advanced manufacturing processes like sintering. Whether you are in R&D or high-volume production, our solutions can help you achieve superior part quality, reduce costs, and unlock new design possibilities.

Contact us today using the form below to discuss how we can support your laboratory and production needs. Let's build superior components together!

Visual Guide

Related Products

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Custom PTFE Teflon Parts Manufacturer for Acid and Alkali Resistant Chemical Powder Material Scoops

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Thermally Evaporated Tungsten Wire for High Temperature Applications

People Also Ask

- How does sintering work ceramics? Unlock the Process for Dense, High-Strength Materials

- What are some applications of brazing? Join Dissimilar Metals with Strong, Leak-Proof Bonds

- How does a continuous belt furnace function during the annealing of Pt electrodes? Scaling Catalytic Performance

- How does temperature affect pyrolysis? Master Product Yields from Biochar to Syngas

- What role does drying or curing equipment play in NSHPC synthesis? Ensuring Structural Precision in Porous Carbons

- What are the considerations of powder metallurgy? Key Factors for Manufacturing Success

- What are the benefits of sintering? Achieve Superior Material Properties from Powder

- What materials are sintered? From Metals to Ceramics, Unlocking Advanced Material Properties