The primary advantages of an oil-free diaphragm vacuum pump are its clean, contamination-free operation and significantly reduced maintenance requirements. Because they use a flexible diaphragm instead of sealed, lubricated parts to create a vacuum, they eliminate the risk of oil mist contaminating sensitive samples, processes, or the working environment. This design makes them exceptionally reliable for long-term, unattended operation.

Choosing an oil-free diaphragm pump is a strategic decision for applications where sample purity and long-term operational simplicity are more critical than achieving the deepest possible vacuum. They trade ultimate vacuum power for exceptional cleanliness and reliability.

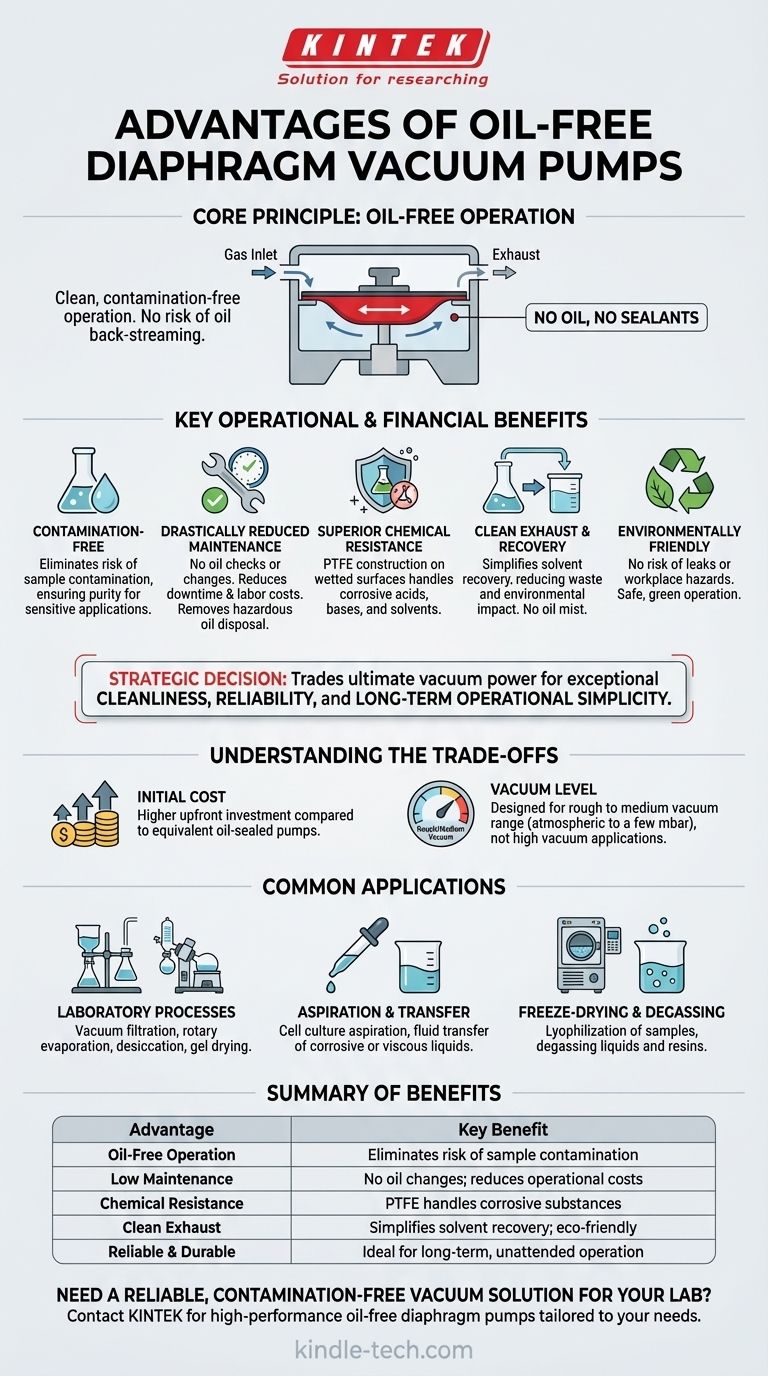

The Core Principle: Oil-Free Operation

The defining feature of a diaphragm pump is its mechanical design, which completely separates it from oil-sealed alternatives like rotary vane pumps. Understanding this principle is key to appreciating its unique benefits.

How a Diaphragm Pump Works

A diaphragm pump creates a vacuum through the reciprocating motion of a flexible, durable membrane (the diaphragm). This diaphragm is moved up and down by a motor-driven cam, which alternately expands and compresses a sealed chamber. This simple action draws gas in through an inlet valve and pushes it out through an exhaust valve, requiring no oil for sealing or lubrication.

The Impact on Sample Purity

The absence of oil is the most critical advantage for scientific and industrial applications. It completely eliminates the risk of oil back-streaming, where oil vapor migrates from the pump into the vacuum system. This ensures that sensitive experiments, sterile processes, or high-purity products remain uncontaminated by hydrocarbon residues.

Streamlined Gas and Solvent Recovery

In applications like rotary evaporation or distillation, vapors are pulled through the vacuum pump. Because a diaphragm pump is oil-free, the exhausted vapors are not mixed with pump oil. This makes it simple to condense and recover valuable solvents on the exhaust side of the pump, reducing waste and cost.

Operational and Financial Benefits

Beyond cleanliness, the oil-free design delivers significant advantages in maintenance, durability, and overall cost of ownership.

Drastically Reduced Maintenance

The most frequent maintenance task for oil-sealed pumps—checking levels and changing the oil—is completely eliminated. This reduces equipment downtime, lowers labor costs, and removes the need to purchase, store, and dispose of vacuum pump oil.

Superior Chemical Resistance

Many high-performance diaphragm pumps are built with PTFE (polytetrafluoroethylene) or other inert fluoropolymers on all "wetted" surfaces. These are the parts that come into contact with the pumped gas. This construction makes them highly resistant to corrosion from aggressive acids, bases, and organic solvents that would quickly degrade standard pumps.

Environmentally Friendly Operation

With no oil, there is no risk of leaks creating workplace hazards or environmental contamination. Furthermore, it eliminates the need for hazardous waste disposal associated with used pump oil, contributing to safer and greener operations.

Understanding the Trade-offs

No technology is perfect for every situation. To make an informed decision, you must be aware of the inherent limitations of diaphragm pumps.

The Initial Purchase Cost

Diaphragm vacuum pumps typically have a higher upfront purchase price compared to an equivalent oil-sealed rotary vane pump. This initial investment must be weighed against the significant long-term savings from eliminated oil costs and drastically reduced maintenance labor.

The Vacuum Level Limitation

This is the most important technical trade-off. Diaphragm pumps are designed for rough to medium vacuum applications, generally operating in a range from atmospheric pressure down to a few millibars (mbar). They cannot achieve the high vacuum levels required for processes like mass spectrometry or electron microscopy, which remain the domain of rotary vane, scroll, and turbomolecular pumps.

Common Applications Where Diaphragm Pumps Excel

The combination of cleanliness, chemical resistance, and low maintenance makes these pumps the ideal choice for specific, demanding tasks.

Laboratory and Analytical Processes

Diaphragm pumps are the standard for benchtop applications like vacuum filtration, solid-phase extraction, desiccation, and gel drying. They are especially critical for rotary evaporators ("rotovaps") where solvent vapors are present.

Aspiration and Fluid Transfer

Their ability to handle moisture and corrosive fumes makes them perfect for cell culture aspiration, pulling fluids from bioreactors, or transferring viscous or acidic liquids in chemical and pharmaceutical manufacturing.

Freeze-Drying and Degassing

They are excellent for freeze-drying (lyophilization) of samples where water vapor is the primary gas load and sample purity is paramount. They are also used for degassing liquids and resins before curing.

Making the Right Choice for Your Goal

Choosing the correct vacuum technology depends entirely on balancing performance needs with your operational priorities.

- If your primary focus is sample purity and low maintenance: An oil-free diaphragm pump is the superior choice, especially for sensitive lab work involving solvents or biologicals.

- If your primary focus is achieving the deepest possible vacuum: You should look to other technologies like an oil-sealed rotary vane pump, understanding it will require regular maintenance and carries a risk of contamination.

- If your primary focus is chemical compatibility: A PTFE-constructed diaphragm pump is purpose-built for handling corrosive vapors and solvents that would destroy other pumps.

Ultimately, an oil-free diaphragm pump is the definitive solution for clean, reliable, and maintenance-free vacuum in the rough to medium pressure range.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Oil-Free Operation | Eliminates risk of sample contamination from oil back-streaming. |

| Low Maintenance | No oil changes; reduces downtime and operational costs. |

| Chemical Resistance | PTFE construction handles corrosive acids, bases, and solvents. |

| Clean Exhaust | Simplifies solvent recovery; environmentally friendly. |

| Reliable & Durable | Ideal for long-term, unattended operation in rough to medium vacuum. |

Need a reliable, contamination-free vacuum solution for your lab?

At KINTEK, we specialize in high-performance oil-free diaphragm vacuum pumps designed for laboratories where sample purity and operational simplicity are critical. Our pumps are built to handle demanding applications like rotary evaporation, filtration, and aspiration with superior chemical resistance and minimal maintenance.

Let KINTEK provide the clean, reliable vacuum your work demands. Contact our experts today to find the perfect pump for your specific needs!

Visual Guide

Related Products

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Variable Speed Peristaltic Pump

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

People Also Ask

- Is sintering eco-friendly? Weighing Material Efficiency Against Energy Use

- What are the steps of the sintering process? A Guide from Powder to Solid Part

- What is the range of sputtering? Achieve High-Quality Thin Films for Any Application

- Why is a high-precision magnetic stirrer essential during the synthesis of silver-silica colloids? Ensure Homogeneity

- What is sintering temperature? Mastering the Key to Powdered Material Performance

- What are the 3 stages of heat treatment? Master Heating, Soaking & Cooling for Superior Material Properties

- Why does melting require energy? Unlock the Science of Latent Heat and Phase Changes

- Which method is best for removing a solid from a liquid? A Guide to Filtration, Decantation, Evaporation & Centrifugation