The Iridium-Tantalum-Titanium Oxygen Evolution Electrode is a specialized anode used in demanding industrial electrolytic processes. Its primary applications include electrometallurgy, advanced wastewater treatment, electroplating, electrosynthesis, and the production of HHO gas, particularly in environments rich with oxyanions like sulfates or carbonates.

This electrode is not a general-purpose tool. It is engineered specifically for one critical task: efficiently generating oxygen at the anode in corrosive, non-chloride electrolytic solutions where lesser materials would quickly fail. Its value lies in its unique combination of high catalytic activity and exceptional durability.

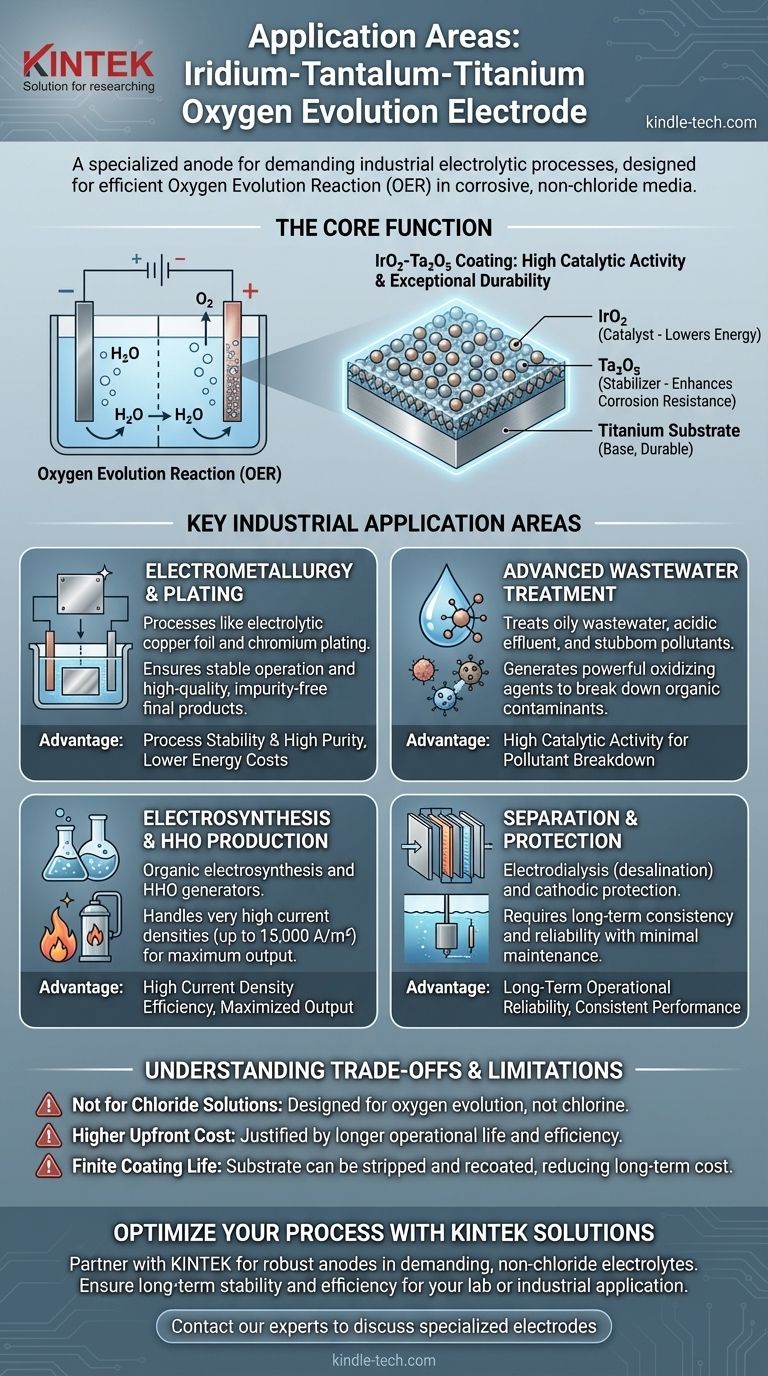

The Core Function: Engineering for a Hostile Environment

To understand the applications, you must first understand the problem this electrode solves. In many industrial processes, the anode's job is to facilitate the Oxygen Evolution Reaction (OER), which is the splitting of water molecules to produce oxygen gas.

The Challenge of Oxygen Evolution

The OER is an energetically demanding reaction. Forcing it to happen efficiently without the anode itself corroding or dissolving is a significant materials science challenge, especially in acidic or other corrosive media.

The IrO₂-Ta₂O₅ Coating Solution

This electrode uses a sophisticated coating on a titanium substrate to overcome this challenge.

- Iridium Oxide (IrO₂): This is the primary catalyst. It has excellent electrocatalytic activity for the OER, meaning it lowers the amount of extra energy (the "overpotential") required to drive the reaction.

- Tantalum Oxide (Ta₂O₅): This acts as a stabilizing agent. It dramatically enhances the coating's corrosion resistance, protecting the catalyst and the underlying titanium from aggressive chemical attack.

Why a Titanium Substrate?

Titanium is used as the base because it is strong, relatively lightweight, and forms a stable, non-conductive oxide layer. When coated with the catalytic mixture, it becomes a durable and reusable foundation for the active electrode surface.

Key Industrial Application Areas

The unique properties of the Iridium-Tantalum-Titanium anode make it the preferred choice in several key sectors where efficiency and longevity are paramount.

Electrometallurgy and Plating

Applications here include electrolytic copper foil production and chromium plating. In these processes, the anode must remain stable and not introduce impurities into the plating bath, ensuring a high-quality final product. Its high current efficiency directly translates to lower energy costs.

Advanced Wastewater Treatment

This is a major application area, covering oily wastewater, acidic industrial effluent, and general wastewater treatment. The electrode's high catalytic activity generates powerful oxidizing agents (like hydroxyl radicals) from water, which effectively break down stubborn organic pollutants that are resistant to other methods.

Electrosynthesis and HHO Production

In organic electrosynthesis and HHO generator applications, the goal is maximizing output. The anode's ability to handle very high current densities (up to 15,000 A/m²) allows for high production rates, while its efficiency ensures that electrical energy is primarily used for the desired reaction, not wasted as heat.

Separation and Protection

In processes like electrodialysis (for desalination or separation) and cathodic protection (for preventing corrosion of submerged metal structures), the anode's long-term stability and reliability are the most critical factors. It must operate consistently for extended periods with minimal maintenance.

Understanding the Trade-offs and Limitations

No electrode is perfect for every situation. Objectivity requires acknowledging this tool's specific purpose and its inherent trade-offs.

Designed for Oxygen, Not Chlorine

This electrode is an oxygen evolution anode. It is specifically designed for electrolytes that do not contain significant levels of chloride ions. In chloride-rich solutions (like brine electrolysis), a different type of anode, typically one with a ruthenium-based coating, is required for chlorine evolution.

The Cost of Performance

Iridium is a precious platinum-group metal. Consequently, the upfront cost of these anodes is higher than that of simpler alternatives like lead or graphite. This cost is justified by significantly longer operational life, higher efficiency (lower power consumption), and the ability to recoat and reuse the titanium substrate.

Finite Coating Life

While highly durable, the catalytic coating has a finite lifespan and will eventually deactivate. A key economic advantage is that the valuable titanium substrate can be stripped of the old coating and recoated multiple times, significantly reducing long-term replacement costs compared to disposable anodes.

Making the Right Choice for Your Goal

Selecting an anode is about matching the material to the specific chemical environment and the desired outcome of your process.

- If your primary focus is high-purity metal plating or winning in sulfate-based solutions: This electrode's stability and low energy consumption make it the ideal choice.

- If your primary focus is breaking down persistent pollutants in industrial wastewater: The high catalytic activity for generating powerful oxidizers is its key advantage.

- If your primary focus is maximizing production in electrosynthesis or HHO generation: Its ability to handle high current densities efficiently is unmatched by lesser materials.

Ultimately, choosing an Iridium-Tantalum-Titanium anode is an investment in process stability, energy efficiency, and long-term operational reliability.

Summary Table:

| Application Area | Key Advantage | Primary Use Case |

|---|---|---|

| Electrometallurgy & Plating | Process Stability & High Purity | Electrolytic copper foil, chromium plating |

| Advanced Wastewater Treatment | High Catalytic Activity | Breakdown of persistent organic pollutants |

| Electrosynthesis & HHO Production | High Current Density Efficiency | Maximizing output in synthesis and gas generation |

| Separation & Protection | Long-Term Operational Reliability | Electrodialysis, cathodic protection systems |

Optimize Your Electrolytic Process with KINTEK Solutions

Are you working with demanding, non-chloride electrolytes where standard anodes fail? The Iridium-Tantalum-Titanium Oxygen Evolution Electrode offers unmatched durability and efficiency for applications like electrometallurgy, advanced wastewater treatment, and electrosynthesis.

As a specialist in high-performance lab equipment and consumables, KINTEK provides the robust anodes your process needs for long-term stability and lower energy costs. Our expertise ensures you get the right solution for your specific chemical environment and production goals.

Contact our experts today to discuss how our specialized electrodes can enhance your lab's efficiency and reliability.

Visual Guide

Related Products

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Platinum Sheet Electrode for Battery Lab Applications

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

- Copper Sulfate Reference Electrode for Laboratory Use

People Also Ask

- How should a platinum sheet electrode be operated during an experiment? Ensure Accurate and Reproducible Results

- What is the most critical guideline for immersing a platinum sheet electrode in an electrolyte? Ensure Accurate Electrochemical Measurements

- What are the performance characteristics of platinum sheet electrodes? Unlock Superior Electrochemical Performance

- What are the key performance characteristics and applications of platinum sheets? Unmatched Reliability for Demanding Applications

- What are the available specifications for platinum sheet electrodes? Find the Perfect Fit for Your Electrochemical Needs