Aluminum casting is a foundational manufacturing process used across nearly every major industry. Its applications range from critical automotive and aerospace components to everyday consumer electronics and cookware, driven by a unique combination of low weight, high strength, excellent thermal conductivity, and corrosion resistance.

The core reason aluminum casting is so widespread is its unmatched versatility. It provides an optimal balance of material properties and manufacturability, allowing engineers to create complex, lightweight, and cost-effective parts that would be difficult or impossible to produce with other materials.

The Core Properties Driving Aluminum's Adoption

To understand its applications, we must first understand the material's inherent advantages. The choice to use aluminum casting is almost always a decision based on one or more of the following key properties.

Exceptional Strength-to-Weight Ratio

This is the most significant advantage of aluminum. Aluminum alloys offer impressive strength while being roughly one-third the weight of steel.

This property is a primary driver in transportation industries, where reducing weight directly translates to improved fuel efficiency and performance.

Superior Thermal and Electrical Conductivity

Aluminum is an excellent conductor of heat and electricity. This makes it the material of choice for applications that require efficient thermal management.

Components like heat sinks in electronics and engine blocks in vehicles rely on this property to dissipate heat quickly and prevent overheating.

Natural Corrosion Resistance

Aluminum naturally forms a thin, dense layer of aluminum oxide on its surface when exposed to air. This passive oxide layer provides outstanding protection against corrosion.

This makes aluminum castings suitable for products used outdoors, in marine environments, or in applications where exposure to moisture is a concern.

Excellent Castability and Design Freedom

Molten aluminum alloys flow with exceptional fluidity, allowing them to fill thin, intricate sections of a mold. This property, known as castability, is a major manufacturing advantage.

It enables the production of complex, near-net-shape parts with fine details, minimizing the need for expensive and time-consuming secondary machining operations.

Key Applications by Industry

These core properties translate directly into specific, high-value applications across various sectors.

Automotive and Transportation

The automotive industry is the largest consumer of aluminum castings. The goal is almost always weight reduction to meet fuel economy and emissions standards.

Common parts include engine blocks, cylinder heads, transmission housings, pistons, suspension components, and wheels.

Aerospace and Defense

In aerospace, every gram matters. The high strength-to-weight ratio makes aluminum casting essential for producing lightweight structural components.

Applications include airframe components, brackets, gearbox housings, and various fittings where reducing mass without compromising safety is critical.

Electronics and Telecommunications

The primary driver for aluminum in electronics is thermal management. The material's ability to dissipate heat is crucial for performance and longevity.

You will find aluminum castings used as heat sinks for CPUs, housings for laptops and servers, and enclosures for telecommunications equipment that protect sensitive internals.

Consumer Goods and Industrial Equipment

Aluminum's corrosion resistance, light weight, and ability to hold a high-quality surface finish make it ideal for a wide range of goods.

This includes cookware like pots and pans, housings for power tools, lighting fixtures, and various components in industrial machinery and robotics.

Understanding the Trade-offs

No material is perfect for every situation. Being an effective advisor means acknowledging the limitations of aluminum casting.

Lower Strength and Hardness Than Steel

While strong for its weight, aluminum does not possess the absolute strength, fatigue resistance, or hardness of steel. For applications under extreme stress or requiring high wear resistance, steel is often the better choice.

Temperature Limitations

Standard aluminum alloys begin to lose a significant amount of their strength at elevated temperatures (typically above 200°C or 400°F).

For very high-temperature environments, such as in jet engine turbines or exhaust components, specialized materials like steel, titanium, or nickel-based superalloys are necessary.

Higher Raw Material Cost

On a per-pound basis, aluminum is typically more expensive than steel. However, this initial cost can often be offset by other factors.

The lower weight reduces shipping costs, and the excellent castability can lower machining expenses, sometimes making the final part cost competitive.

Making the Right Choice for Your Goal

Selecting the right material is about matching its properties to the primary objective of your project.

- If your primary focus is maximum weight reduction (e.g., automotive, aerospace): Aluminum casting is the default choice for a huge range of structural and powertrain components.

- If your primary focus is thermal management (e.g., electronics, LED lighting): The high thermal conductivity of cast aluminum makes it the ideal material for heat sinks and enclosures.

- If your primary focus is absolute strength and high-temperature performance (e.g., high-stress gears, engine turbines): You should look to other materials and processes, such as forged steel or titanium alloys.

- If your primary focus is producing a complex shape at a low cost (e.g., enclosures, decorative parts): Aluminum's excellent castability allows for near-net-shape parts that require minimal secondary processing.

Ultimately, understanding the fundamental properties of aluminum allows you to leverage it as a powerful and versatile solution to a vast array of engineering challenges.

Summary Table:

| Industry | Key Applications | Primary Driver |

|---|---|---|

| Automotive & Transportation | Engine blocks, cylinder heads, wheels | Weight reduction for fuel efficiency |

| Aerospace & Defense | Airframe components, housings, brackets | High strength-to-weight ratio |

| Electronics & Telecommunications | CPU heat sinks, server housings | Superior thermal management |

| Consumer Goods & Industrial | Cookware, power tool housings, machinery parts | Corrosion resistance & design freedom |

Need a Custom Aluminum Casting Solution for Your Lab Equipment?

KINTEK specializes in providing high-quality lab equipment and consumables. Whether you're developing complex instrument housings, custom heat sinks for analytical devices, or durable components for your laboratory machinery, our expertise in material science can help you select the right aluminum casting process for optimal performance and cost-efficiency.

Contact our experts today to discuss how we can support your specific laboratory needs with precision-cast aluminum components.

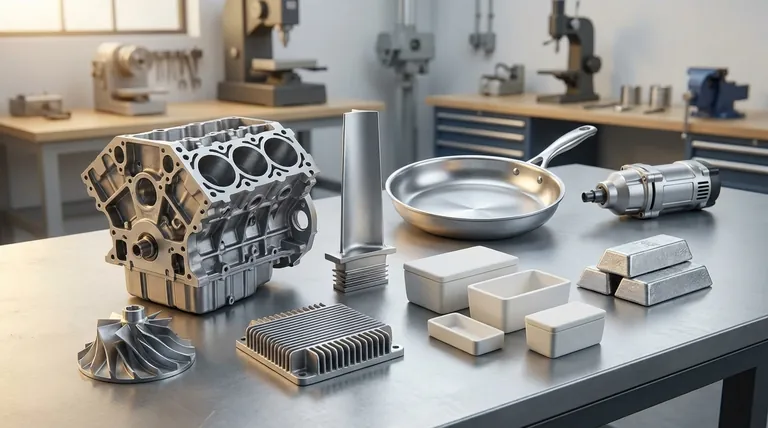

Visual Guide

Related Products

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Custom PTFE Teflon Parts Manufacturer for Culture Dish and Evaporation Dish

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Custom PTFE Teflon Parts Manufacturer for Hydrothermal Synthesis Reactor Polytetrafluoroethylene Carbon Paper and Carbon Cloth Nano-growth

People Also Ask

- Why must aluminum alloys be heated in alumina crucibles? Ensure Pure Results in Molten Corrosion Experiments

- Why is a high-purity alumina crucible required for LLTO calcination? Ensure Material Purity and Stoichiometry

- What is the purpose of using alumina crucibles as liners in autoclaves? Ensure Purity in High-Pressure Static Tests

- What is the function of an alumina crucible in NaSICON synthesis? Ensure Purity in High-Temperature Reactions

- What is a crucible porcelain? Choosing the Right High-Temperature Lab Vessel