In modern manufacturing, the molding process—especially injection molding—is a foundational technology used to create a vast range of plastic parts across nearly every industry. Its applications include critical automotive components like dashboards and bumpers, high-precision medical devices such as syringes, and everyday consumer goods from bottle caps to electronic enclosures.

The core value of molding lies in its ability to produce highly complex and precise parts with exceptional consistency, making it the definitive choice for high-volume manufacturing where per-unit cost is a critical factor.

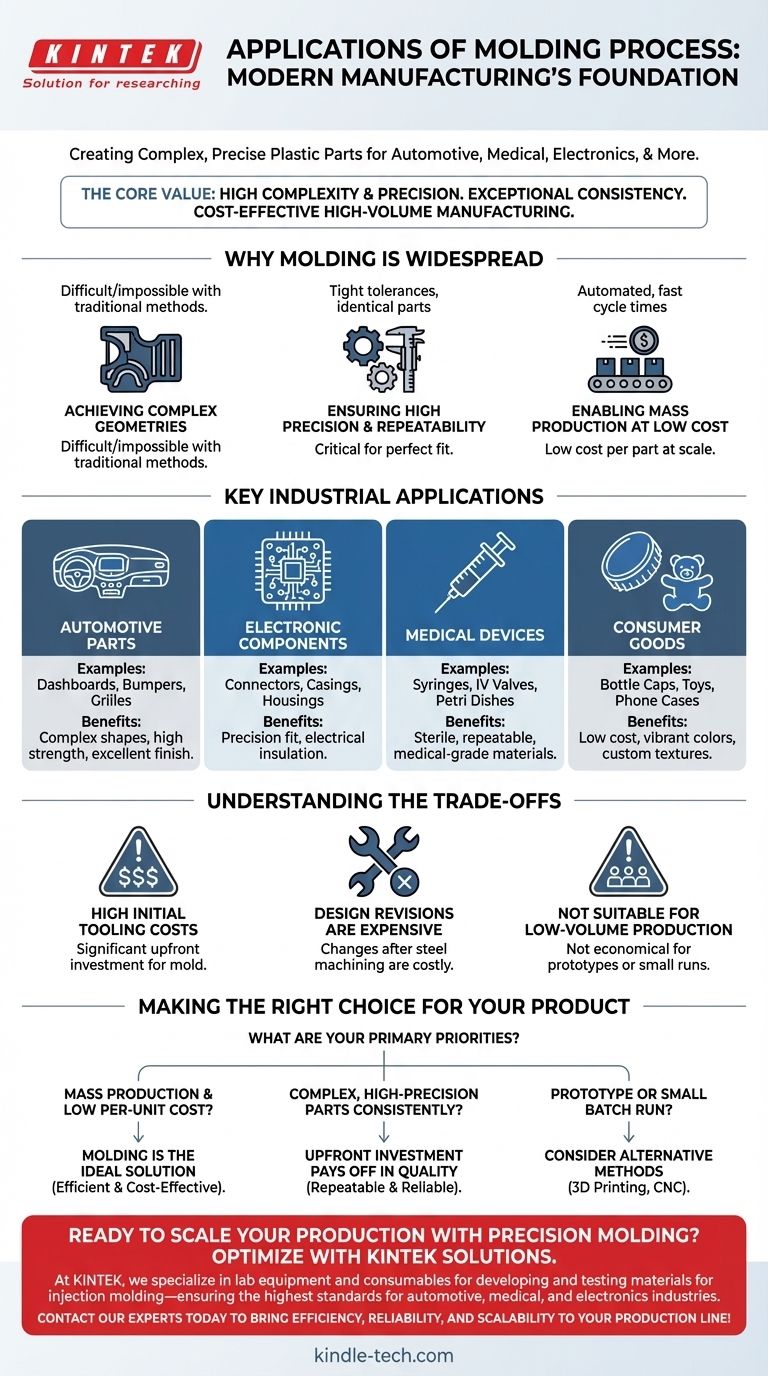

Why Molding is So Widespread

The versatility of molding comes from a few core principles that make it uniquely suited for mass production. These advantages explain its dominance in fields that demand precision, repeatability, and scale.

Achieving Complex Geometries

Molding allows for the creation of intricate shapes, including complex curves, ribs, and bosses, in a single step. This is a level of design freedom that is difficult or impossible to achieve economically with traditional machining methods.

Ensuring High Precision and Repeatability

A well-made mold can produce millions of identical parts with extremely tight tolerances. This consistency is critical for components that must fit together perfectly, such as electronic enclosures or automotive interior panels.

Enabling Mass Production at Low Cost

While the initial investment in a mold (tooling) can be high, the cost per individual part becomes incredibly low once production begins. Automated processes and fast cycle times make it the most cost-effective method for manufacturing at scale.

Key Industrial Applications

The principles of precision, complexity, and scale directly translate into a wide array of real-world products.

Automotive Parts

Components like dashboards, bumpers, and grilles require a combination of structural integrity, complex shapes, and a high-quality surface finish. Molding efficiently delivers all three requirements in a single, repeatable process.

Electronic Components

Molding is essential for producing electrical connectors, device casings, and protective housings. The process provides the necessary precision for a perfect fit and leverages plastics for their excellent electrical insulation properties.

Medical Devices

For items like syringes, IV valves, and petri dishes, molding provides a sterile, repeatable manufacturing process. Specific medical-grade polymers can be used, ensuring the final product is safe for clinical use and can be produced in massive quantities.

Consumer Goods

From toys and mobile phone cases to bottle caps, molding is the engine behind countless consumer products. It allows for vibrant colors, custom textures, and low production costs, making these everyday items accessible.

Understanding the Trade-offs

Despite its benefits, molding is not the right solution for every project. Understanding its limitations is key to using it effectively.

High Initial Tooling Costs

The primary barrier to entry is the cost of designing and fabricating the steel mold. This upfront investment can range from thousands to hundreds of thousands of dollars, depending on the part's complexity.

Design Revisions are Expensive

Once the mold is machined from steel, making changes is difficult and costly. This means the part design must be thoroughly tested and finalized before committing to tooling.

Not Suitable for Low-Volume Production

Due to the high initial investment, molding is not economical for small production runs or one-off prototypes. The cost-per-part only becomes advantageous at high volumes that spread out the initial tooling expense.

Making the Right Choice for Your Product

To determine if molding is the correct approach, evaluate your project's core priorities.

- If your primary focus is mass production and low per-unit cost: Molding is almost certainly the most efficient manufacturing method for your part.

- If your primary focus is creating complex, high-precision parts consistently: The upfront investment in a mold pays for itself in quality, repeatability, and reliability at scale.

- If your primary focus is a prototype or a small batch run: Consider alternative methods like 3D printing or CNC machining before committing to the high cost of a mold.

Ultimately, choosing molding is a strategic decision to prioritize scalability and long-term cost efficiency over low initial investment.

Summary Table:

| Application Area | Key Examples | Core Benefit |

|---|---|---|

| Automotive | Dashboards, bumpers, grilles | Complex shapes, high strength, excellent finish |

| Medical Devices | Syringes, IV valves, petri dishes | Sterility, precision, medical-grade materials |

| Electronics | Connectors, device casings, housings | Precision fit, electrical insulation |

| Consumer Goods | Bottle caps, toys, phone cases | Low cost per part, vibrant colors, custom textures |

Ready to Scale Your Production with Precision Molding?

If your project demands high-volume manufacturing of complex plastic parts with exceptional consistency and low per-unit cost, the molding process is your ideal solution. At KINTEK, we specialize in providing the lab equipment and consumables necessary for developing and testing materials perfect for injection molding—ensuring your products meet the highest standards for industries like automotive, medical, and electronics.

Let us help you optimize your manufacturing process. Contact our experts today to discuss how our solutions can bring efficiency, reliability, and scalability to your production line!

Visual Guide

Related Products

- Isostatic Molding Pressing Molds for Lab

- Laboratory Hybrid Tissue Grinding Mill

- Custom PTFE Teflon Parts Manufacturer for Culture Dish and Evaporation Dish

- Custom PTFE Teflon Parts Manufacturer for Hollow Etching Flower Basket ITO FTO Developing Glue Removal

- Three-dimensional electromagnetic sieving instrument

People Also Ask

- What are the 5 steps of injection molding? A Guide to Efficient, High-Quality Production

- What is a press mold used for? Achieve Repeatable Precision and Efficiency

- What is the difference between two plate and three plate mold? Choose the Right Mold for Your Project

- What role does a graphite mold play in vacuum hot-pressing graphene/alumina ceramics? Boost Sintering Precision

- What roles do high-strength graphite dies play in SPS of WC composites? Optimize Heat & Pressure for Density

- What role do high-strength graphite molds play in Fe-Cu sintering? Optimize Your Hot Press Performance

- What is the process of mold press? A Step-by-Step Guide to Compression Molding

- What is the purpose of using precision limiting molds or spacers? Achieve Uniform Electrolyte Membrane Thickness