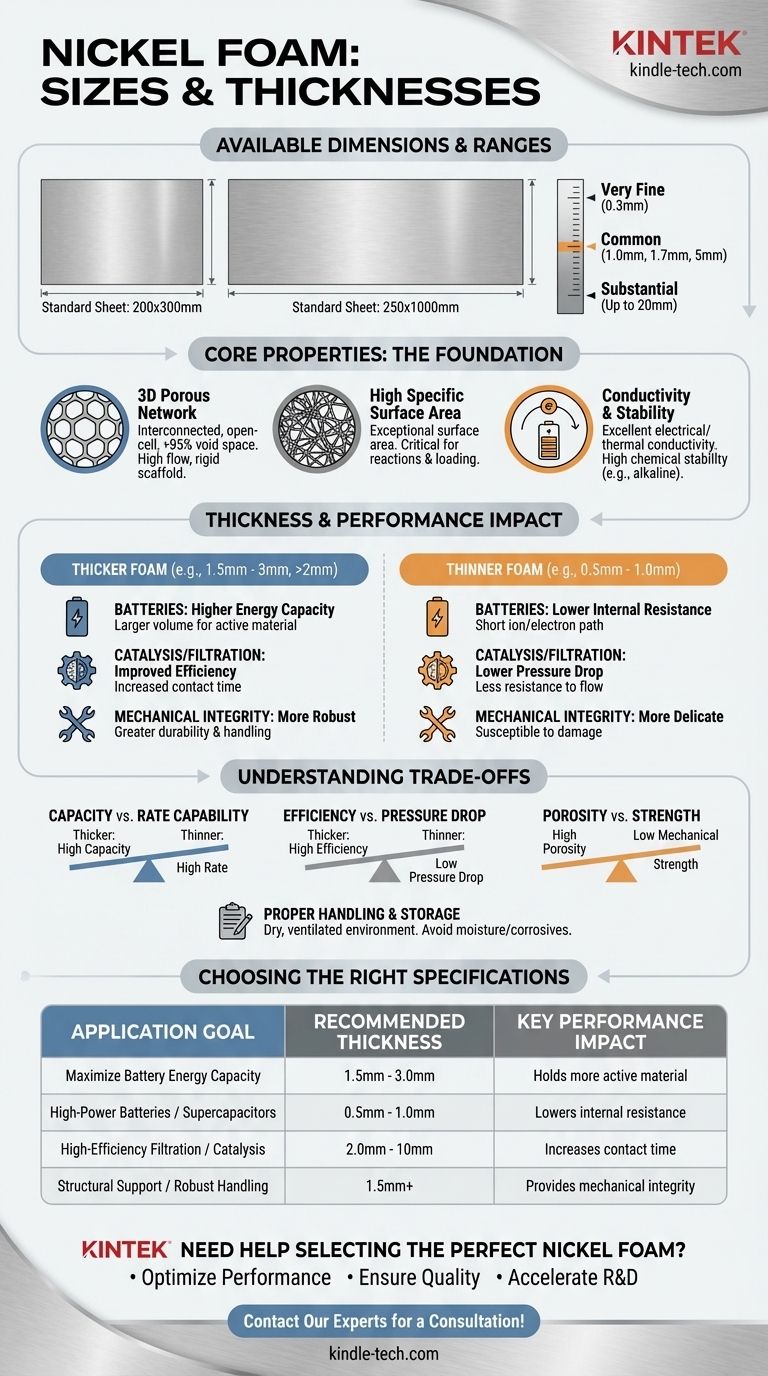

When selecting nickel foam for a technical application, you will find it is commonly available in standard sheet dimensions of 200x300mm and 250x1000mm. The material is produced in a wide array of thicknesses, typically ranging from a very fine 0.3mm up to a substantial 20mm, with common intermediate steps like 1.0mm, 1.7mm, and 5mm also available.

The key to selecting the right nickel foam is understanding that its thickness is not just a physical dimension, but a critical design parameter. This choice directly controls performance metrics like energy capacity in batteries, efficiency in catalysts, and structural integrity.

Understanding Nickel Foam's Core Properties

To choose the correct thickness, you must first understand the fundamental properties that make nickel foam a unique and valuable engineering material. Its performance stems directly from its specialized microstructure.

The Three-Dimensional Porous Network

Nickel foam is not simply a sheet of metal with holes. It consists of an interconnected, open-cell network of nickel ligaments, creating a structure that is both highly porous (often over 95% void space) and continuous.

This structure allows fluids or electrolytes to flow through it with minimal obstruction while providing a rigid, conductive scaffold.

High Specific Surface Area

The complex, web-like structure results in an exceptionally large surface area relative to the foam's volume. This is a critical feature for applications that rely on surface reactions or material loading.

Electrical Conductivity and Chemical Stability

As a metallic material, nickel foam offers excellent electrical and thermal conductivity. It is also known for its high chemical stability, particularly in the alkaline environments common in nickel-metal hydride (NiMH) and other battery systems.

How Thickness Dictates Performance

The choice of thickness is a primary engineering decision that directly impacts how the foam will perform in your specific application. A thicker foam is not inherently better; it is simply different.

For Battery Electrodes

In batteries, the foam acts as a current collector and a host for the active electrode material. A thicker foam (e.g., 1.5mm - 3mm) can hold a larger volume of active material, which directly translates to higher energy storage capacity.

Conversely, a thinner foam (e.g., 0.5mm - 1.0mm) reduces the path length for ions and electrons. This lowers internal resistance and is critical for high-power applications where rapid charging and discharging are required.

For Catalysis and Filtration

When used as a catalyst support or filter medium, a thicker piece of foam increases the residence time—the duration a fluid is in contact with the nickel surface. This can significantly improve reaction or filtration efficiency.

The trade-off is that a thicker, longer path creates more resistance to flow, resulting in a higher pressure drop across the foam.

For Mechanical Integrity

Thicker foams are inherently more rigid and robust. If your application involves mechanical stress or requires easier handling during assembly, a thicker material (e.g., >2mm) provides greater durability and resistance to bending or tearing. Extremely thin foams (<0.5mm) can be quite delicate.

Understanding the Trade-offs

Selecting nickel foam involves balancing competing properties. Recognizing these trade-offs is crucial for avoiding common design pitfalls and optimizing your system.

Capacity vs. Rate Capability

This is the classic trade-off in battery design. Increasing foam thickness to boost energy capacity can negatively impact rate capability (how fast you can access that energy) due to increased transport resistance.

Efficiency vs. Pressure Drop

In any flow-through system like a filter or reactor, maximizing the surface area and contact time with a thicker foam will almost always increase the pressure drop. This must be factored into the design of your pumps and overall system energy consumption.

Porosity vs. Strength

While nickel foam's high porosity is its main advantage, it comes at the expense of the mechanical strength of solid nickel. The foam's open-cell structure makes it susceptible to compression damage if mishandled.

Proper Handling and Storage

To maintain its properties, nickel foam must be stored in a dry, well-ventilated environment. Exposure to moisture or corrosive substances like strong acids and alkalis will degrade the material and compromise its performance, especially in sensitive electrochemical applications.

Choosing the Right Specifications for Your Application

Your selection should be driven by the primary technical goal of your project. Use the following guidelines to make an informed decision.

- If your primary focus is maximizing battery energy capacity: Opt for a thicker foam (e.g., 1.5mm - 3.0mm) to load more active material, accepting a potential compromise in power density.

- If your primary focus is high-power batteries or supercapacitors: Choose a thinner foam (e.g., 0.5mm - 1.0mm) to minimize electrical and ionic resistance for superior rate performance.

- If your primary focus is high-efficiency filtration or catalysis: Select a medium-to-thick foam (e.g., 2.0mm - 10mm) to increase contact time, carefully balancing this against the acceptable pressure drop for your system.

- If your primary focus is structural support or robust handling: A thickness of 1.5mm or greater will provide the necessary mechanical integrity for easier assembly and durability.

By aligning the foam's thickness with your specific performance goal, you move from simply fitting a component to engineering a solution.

Summary Table:

| Application Goal | Recommended Thickness | Key Performance Impact |

|---|---|---|

| Maximize Battery Energy Capacity | 1.5mm - 3.0mm | Holds more active material |

| High-Power Batteries / Supercapacitors | 0.5mm - 1.0mm | Lowers internal resistance |

| High-Efficiency Filtration / Catalysis | 2.0mm - 10mm | Increases contact time |

| Structural Support / Robust Handling | 1.5mm+ | Provides mechanical integrity |

Need Help Selecting the Perfect Nickel Foam?

Choosing the right thickness and size is critical for your project's success in batteries, catalysis, or filtration. KINTEK specializes in high-quality lab equipment and consumables, including nickel foam tailored to your specific laboratory and R&D needs.

We can help you:

- Optimize Performance: Match the foam's specifications to your exact application requirements.

- Ensure Quality: Source reliable, consistent nickel foam with the properties you depend on.

- Accelerate R&D: Get the right materials faster, so you can focus on innovation.

Let's engineer your solution together. Contact our experts today for a consultation!

Visual Guide

Related Products

- Conductive Carbon Cloth Carbon Paper Carbon Felt for Electrodes and Batteries

- Electrode Polishing Material for Electrochemical Experiments

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

- Aluminum-Plastic Flexible Packaging Film for Lithium Battery Packaging

- Custom PTFE Teflon Parts Manufacturer for PTFE Containers

People Also Ask

- Why are molten salt electrolytes important for Lithium-Air batteries? High-Performance Consumables for Energy Storage

- What is the purpose of using CR2032 coin cell cases for zinc-ion MXene battery testing? Ensure Precision in Research

- How do heating or UV curing devices influence solid-state batteries? Expert Insights on In-Situ Polymerization

- Why heat treat LLZO in an argon glove box? Remove Passivation Layers & Ensure Superior Surface Purity

- How should nickel or copper foam be handled during an experiment? Protect Your Sample's Critical Porous Structure

- What are the advantages of using high-grade stainless steel for experimental Zinc-Air battery cells? Ensure Precision.

- Why is a dual-chamber reactor structure typically chosen for assembling BMFCs? Ensure High Electrical Potential

- Can carbon nanotubes store energy? Unlock High-Power, Long-Life Energy Storage