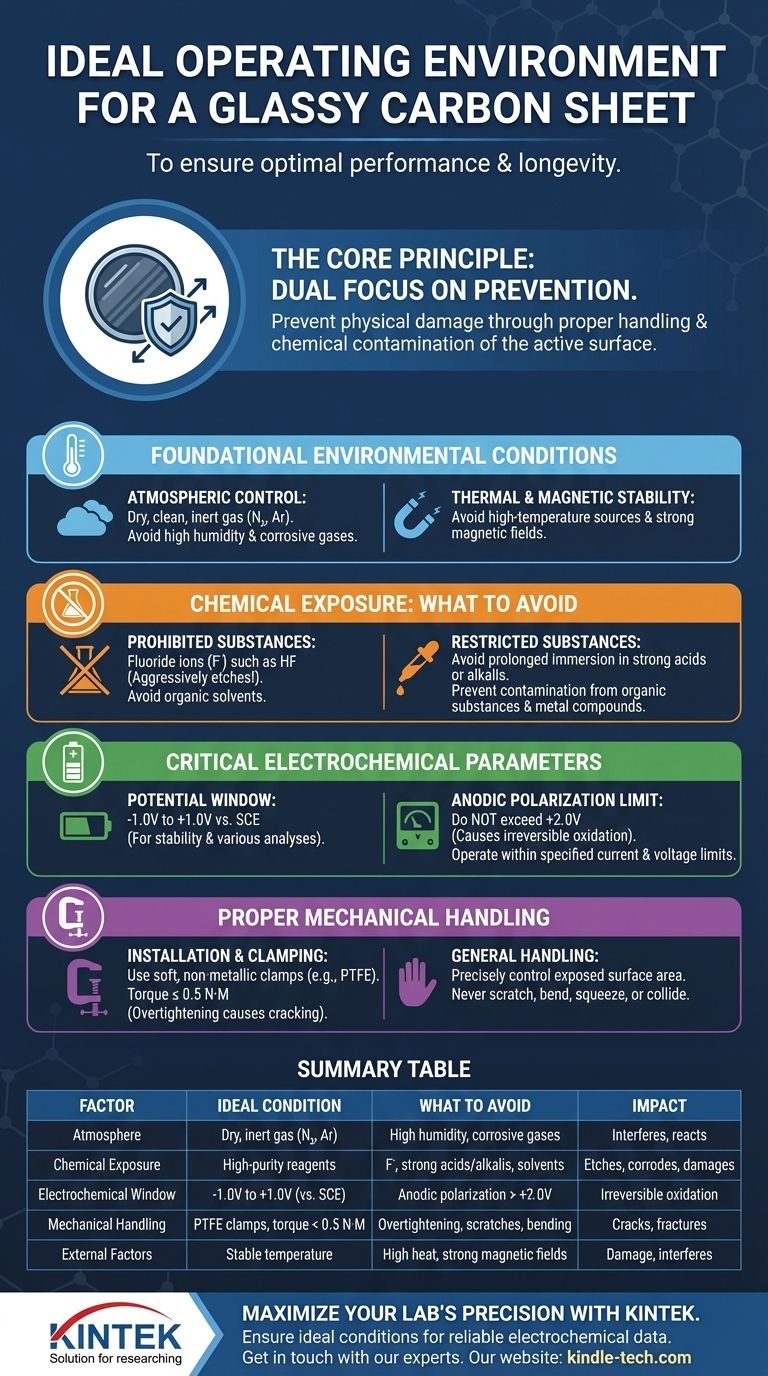

To ensure optimal performance, a glassy carbon sheet must be operated in a dry, clean, and non-corrosive gas environment. It is equally critical to avoid conditions of high temperature, high humidity, and strong magnetic fields, as these factors can degrade its sensitive electrochemical properties and physical integrity.

The core principle for operating a glassy carbon sheet is a dual focus on prevention: preventing physical damage through proper handling and preventing chemical contamination or degradation of its electrochemically active surface.

Foundational Environmental Conditions

Your primary goal is to create an inert and stable baseline environment. This ensures that any changes you observe are due to your experiment, not uncontrolled external variables.

Atmospheric Control

The ideal atmosphere is a dry, clean, and non-corrosive gas, such as nitrogen or argon.

High humidity can introduce a layer of water on the surface, interfering with electrochemical measurements and potentially reacting with analytes.

Thermal and Magnetic Stability

Avoid placing the sheet near high-temperature sources. Overheating can cause structural damage or unwanted surface reactions.

Similarly, strong magnetic fields should be avoided, as they can interfere with electrochemical processes and affect the accuracy of your results.

Chemical Exposure: What to Avoid

The chemical inertness of glassy carbon has limits. Certain substances can irreversibly damage the surface, compromising all future experiments.

Prohibited Substances

The most critical prohibition is against any solution containing fluoride ions (F⁻), such as hydrofluoric acid (HF). Fluoride aggressively etches the carbon surface.

You should also avoid contact with organic solvents known to corrode or dissolve carbonaceous materials.

Restricted Substances

While generally robust, prolonged immersion in strong acid or strong alkali solutions should be avoided.

Contamination from organic substances and metal compounds must be prevented by maintaining a clean workspace and using high-purity reagents.

Critical Electrochemical Parameters

Operating outside the specified electrical limits is a primary cause of irreversible damage to glassy carbon electrodes.

Potential Window

The typical applicable potential range for a glassy carbon sheet is approximately -1.0V to +1.0V versus a saturated calomel electrode (SCE).

Operating within this window ensures the stability of the material and accommodates a wide variety of electrochemical analyses.

Anodic Polarization Limit

Do not apply an anodic polarization exceeding +2.0V. Potentials above this threshold cause irreversible oxidation of the carbon surface, permanently altering its properties.

Always operate within the specified current and voltage limits for your specific sheet to prevent electrical damage.

Proper Mechanical Handling

Glassy carbon is a brittle material. Physical stress is a common and entirely preventable cause of failure.

Installation and Clamping

Use a soft, non-metallic clamp, such as one made from PTFE (polytetrafluoroethylene), to hold the sheet.

Apply a torque of no more than 0.5 N·M during installation. Overtightening is a leading cause of cracking.

General Handling

The exposed surface area for your experiment should be precisely controlled, with an error of less than 3%.

Never scratch the surface with metal tools or hard implements. Avoid excessive bending, squeezing, or collisions to prevent fractures.

Making the Right Choice for Your Goal

Your operational priorities will determine which precautions are most critical.

- If your primary focus is material longevity: Prioritize correct mechanical handling, avoiding physical stress, and staying well within the specified voltage and current limits.

- If your primary focus is electrochemical accuracy: Emphasize maintaining a pristine, contamination-free environment and strictly avoiding prohibited chemical agents like fluoride ions.

By treating the glassy carbon sheet as a precision instrument, you will ensure its reliability and the integrity of your results.

Summary Table:

| Environmental Factor | Ideal Condition | What to Avoid |

|---|---|---|

| Atmosphere | Dry, clean, inert gas (N₂, Ar) | High humidity, corrosive gases |

| Chemical Exposure | High-purity reagents | Fluoride ions (F⁻), strong acids/alkalis |

| Electrochemical Window | -1.0V to +1.0V (vs. SCE) | Anodic polarization > +2.0V |

| Mechanical Handling | PTFE clamps, torque < 0.5 N·M | Overtightening, scratches, bending |

| External Factors | Stable temperature | High heat sources, strong magnetic fields |

Maximize Your Lab's Precision with KINTEK

Ensuring the ideal operating environment for sensitive materials like glassy carbon sheets is crucial for reliable electrochemical data and long-term equipment value. At KINTEK, we specialize in providing the high-purity lab equipment and consumables your research demands.

Let us help you achieve consistent, accurate results. Our experts can assist you in selecting the right equipment and establishing best practices for handling and maintaining sensitive electrodes.

Contact us today to discuss your specific laboratory needs and discover how KINTEK's solutions can enhance your workflow and protect your investment.

Get in touch with our experts now

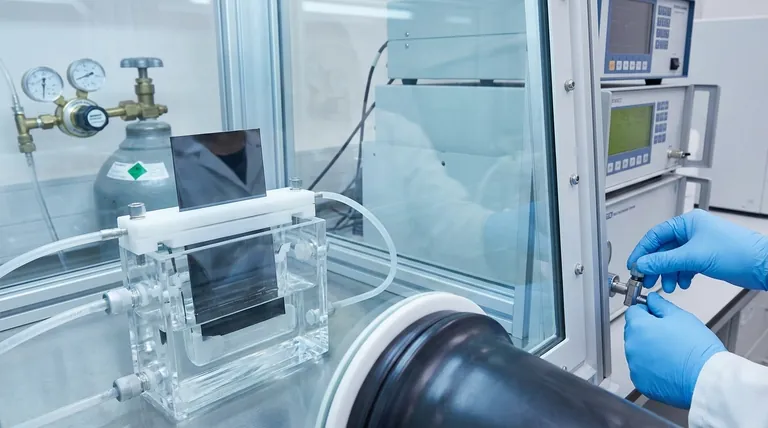

Visual Guide

Related Products

- Conductive Carbon Cloth Carbon Paper Carbon Felt for Electrodes and Batteries

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- Electrode Polishing Material for Electrochemical Experiments

- Optical Ultra-Clear Glass Sheet for Laboratory K9 B270 BK7

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

People Also Ask

- What applications is carbon felt suitable for? Ideal for High-Performance Electrochemical Systems

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- What are the four main types of sensors? A Guide to Power Source and Signal Type

- What are 3 products that carbon nanotubes can be used in? Enhancing Batteries, Tires, and Composites

- What can carbon nanotubes be used for? Unlock Superior Performance in Batteries & Materials