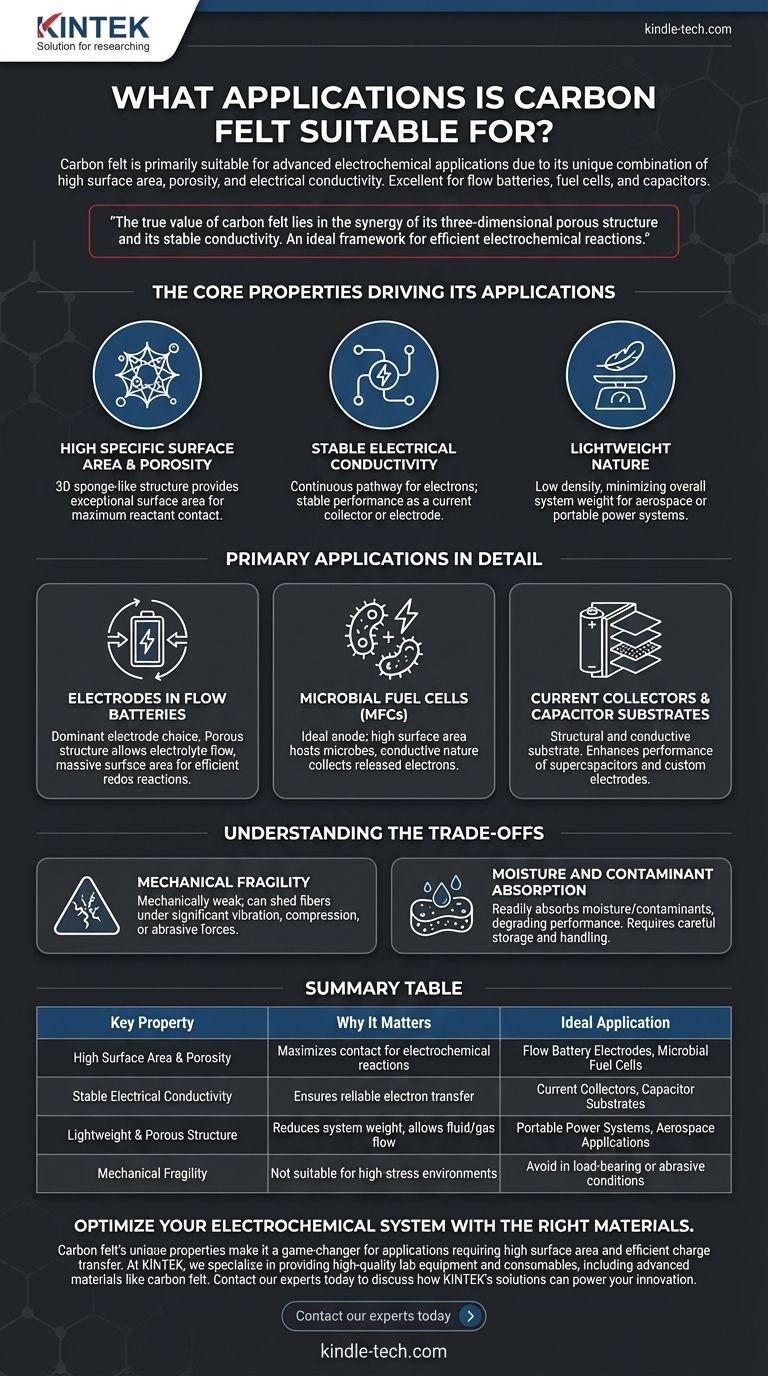

In short, carbon felt is primarily suitable for advanced electrochemical applications due to its unique combination of high surface area, porosity, and electrical conductivity. It serves as an excellent electrode material in systems like flow batteries, fuel cells, and certain types of capacitors where efficient interaction between an electrolyte and an electrode is critical.

The true value of carbon felt lies not in any single property, but in the synergy of its three-dimensional porous structure and its stable conductivity. This makes it an ideal framework for electrochemical reactions that require both a high surface area and an efficient pathway for electron transfer.

The Core Properties Driving Its Applications

To understand where carbon felt excels, you must first understand its fundamental material characteristics. These properties are what define its role in specialized technical fields.

High Specific Surface Area & Porosity

Carbon felt is not a solid sheet but a web of interconnected carbon fibers, creating a three-dimensional, sponge-like structure.

This porous nature provides an exceptionally high surface area relative to its volume. This is critical for applications where a liquid or gas reactant must make maximum contact with a surface to react, such as in a battery electrolyte.

Stable Electrical Conductivity

The interconnected carbon fibers create a continuous pathway for electrons to flow. This makes the entire felt structure electrically conductive.

Unlike some materials whose conductivity changes drastically with temperature or age, carbon felt's conductivity is stable, ensuring reliable performance as a current collector or electrode.

Lightweight Nature

As a porous material composed of lightweight carbon, felt has a very low density. This makes it an attractive choice for applications where minimizing overall system weight is a design goal, such as in aerospace or portable power systems.

Primary Applications in Detail

The unique properties of carbon felt make it the material of choice for several specific and demanding applications.

Electrodes in Flow Batteries

In a redox flow battery, carbon felt is the dominant choice for the electrode. Its porous structure allows the liquid electrolyte to flow through it, while its massive surface area provides ample sites for the electrochemical reactions (oxidation and reduction) to occur efficiently.

Microbial Fuel Cells (MFCs)

In an MFC, microorganisms are used to generate electricity from organic matter. Carbon felt serves as an ideal anode because its high surface area provides a vast habitat for microbes to colonize and its conductive nature efficiently collects the electrons they release.

Current Collectors & Capacitor Substrates

Carbon felt can act as a structural and conductive substrate. Other, more active materials can be deposited onto its fibers.

In this role, the felt provides a high-surface-area backbone that is both lightweight and electrically connected, enhancing the performance of supercapacitors or other custom electrode assemblies.

Understanding the Trade-offs

While powerful, carbon felt is not a universal solution. Acknowledging its limitations is key to using it successfully.

Mechanical Fragility

The same porous structure that gives carbon felt its high surface area also makes it mechanically weak compared to solid graphite plates or metal foils.

The material can shed fibers if subjected to significant vibration, compression, or abrasive forces. This must be accounted for in the design of the housing or cell that contains it.

Moisture and Contaminant Absorption

Its porous, sponge-like nature means carbon felt will readily absorb moisture and other contaminants from the air.

This can degrade its performance, especially in sensitive electrochemical systems. For this reason, it must be stored in a sealed, dry environment and handled carefully to prevent contamination before use.

Making the Right Choice for Your Application

Use these guidelines to determine if carbon felt is the appropriate material for your project.

- If your primary focus is high-performance electrochemical reactions: Carbon felt is an excellent choice for an electrode in flow batteries, fuel cells, or similar systems that depend on efficient mass and charge transfer.

- If your primary focus is structural integrity or load-bearing: You should seek an alternative, as carbon felt's mechanical fragility makes it unsuitable for applications requiring high strength or abrasion resistance.

- If your primary focus is simple electrical conduction on a flat surface: A less expensive material like graphite foil or a metal sheet may be a more practical and robust choice.

Ultimately, selecting carbon felt is a decision to prioritize electrochemical surface area and reactant flow over mechanical robustness.

Summary Table:

| Key Property | Why It Matters | Ideal Application |

|---|---|---|

| High Surface Area & Porosity | Maximizes contact for electrochemical reactions | Flow Battery Electrodes, Microbial Fuel Cells |

| Stable Electrical Conductivity | Ensures reliable electron transfer | Current Collectors, Capacitor Substrates |

| Lightweight & Porous Structure | Reduces system weight, allows fluid/gas flow | Portable Power Systems, Aerospace Applications |

| Mechanical Fragility | Not suitable for high-stress environments | Avoid in load-bearing or abrasive conditions |

Optimize your electrochemical system with the right materials.

Carbon felt's unique properties make it a game-changer for applications requiring high surface area and efficient charge transfer. At KINTEK, we specialize in providing high-quality lab equipment and consumables, including advanced materials like carbon felt, to meet the precise needs of research and industrial laboratories.

Whether you're developing next-generation flow batteries or enhancing fuel cell performance, our expertise ensures you get the right materials for superior results.

Contact our experts today to discuss how KINTEK's solutions can power your innovation.

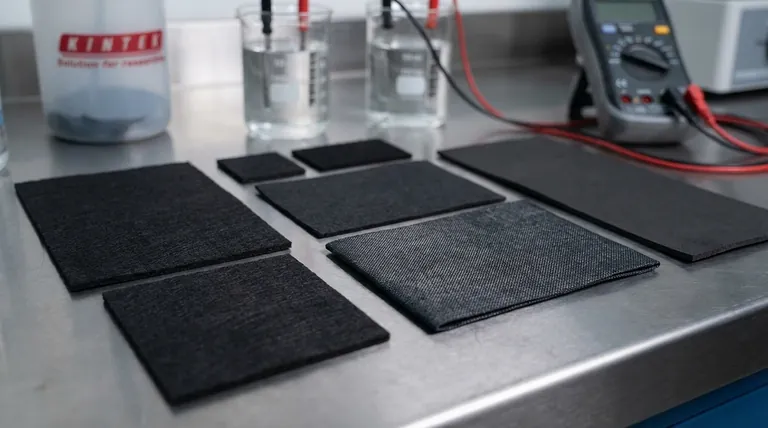

Visual Guide

Related Products

- Conductive Carbon Cloth Carbon Paper Carbon Felt for Electrodes and Batteries

- Electrode Polishing Material for Electrochemical Experiments

- Evaporation Boat for Organic Matter

- Custom PTFE Teflon Parts Manufacturer for Hollow Cleaning Basket and Rack Carrier

- Custom PTFE Teflon Parts Manufacturer for Hollow Etching Flower Basket ITO FTO Developing Glue Removal

People Also Ask

- Why are high surface area materials preferred for BES anodes? Maximize Microbial Power and Efficiency

- What are the common applications for carbon cloth? Unlock Its Potential in Energy & Electrochemical Systems

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- How should carbon cloth used for high-temperature electrolysis be handled after operation? Prevent Irreversible Oxidative Damage

- What are the material properties of carbon paper? Unlocking High Conductivity & Porosity for Your Lab