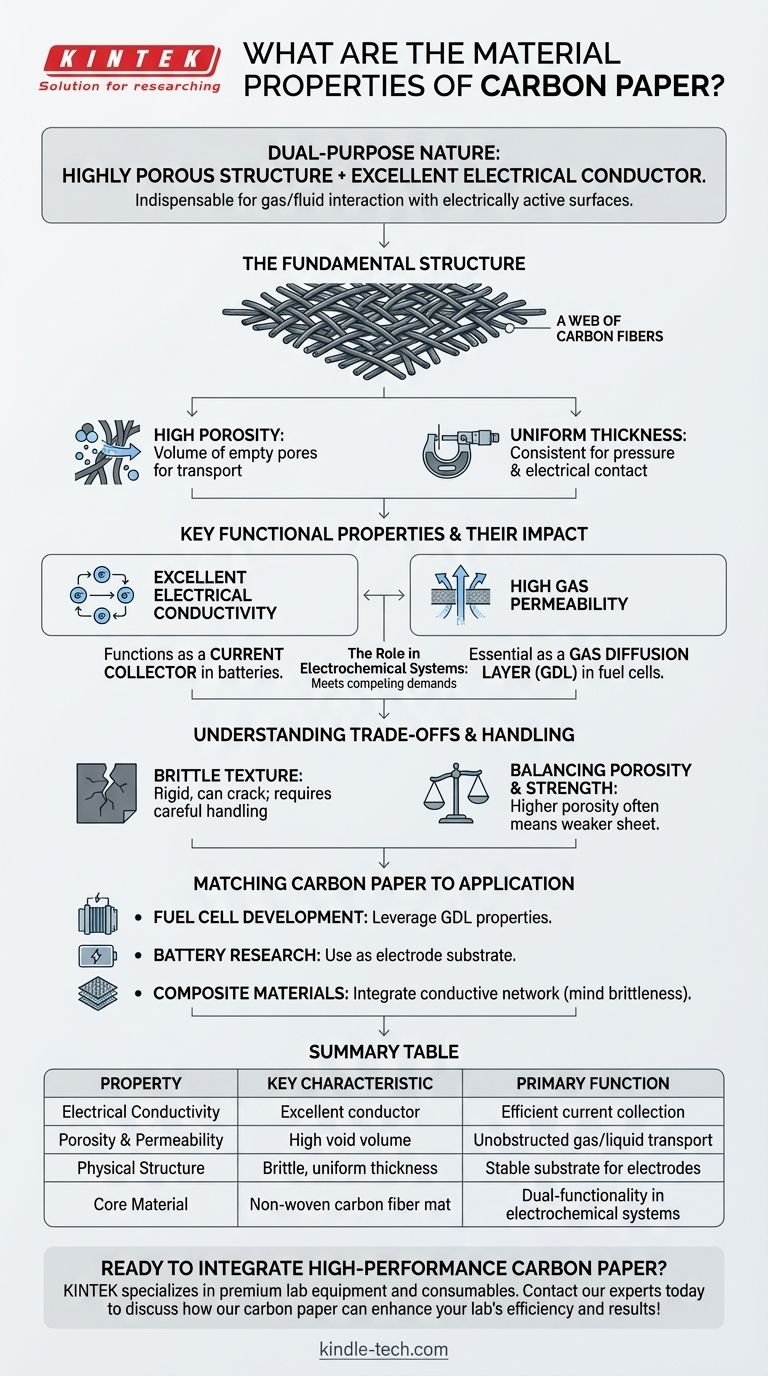

At its core, carbon paper is defined by a unique set of material properties. It is a thin, sheet-like material characterized by its high porosity, excellent electrical conductivity, high air permeability, and uniform thickness. However, it is also known for having a brittle texture, which requires careful handling.

The true value of carbon paper lies in its dual-purpose nature. It is simultaneously a highly porous physical structure and an excellent electrical conductor, making it indispensable for applications where fluids or gases must interact with an electrically active surface.

The Fundamental Structure of Carbon paper

Carbon paper’s properties are a direct result of how it is made. Understanding its composition is key to understanding its function.

A Web of Carbon Fibers

Carbon paper is not a traditional paper made from cellulose. Instead, it is a non-woven mat of carbon fibers that have been pressed and bonded together.

This fibrous, web-like structure is the origin of its most important characteristics.

High Porosity Explained

Porosity refers to the volume of empty space, or pores, within the material. The gaps between the tangled carbon fibers give the material its high porosity.

This internal void space is critical for applications that require the transport of liquids or gases through the material itself.

Uniform Thickness

The manufacturing process ensures a very uniform thickness across the entire sheet.

This consistency is crucial for creating even pressure distribution and reliable electrical contact when carbon paper is used as a component in a larger assembly, like a fuel cell stack.

Key Functional Properties and Their Impact

Each property enables carbon paper to perform a specific technical role, most notably in electrochemical systems.

Excellent Electrical Conductivity

Because it is made entirely of carbon, the material is an excellent electrical conductor.

This allows it to function as a current collector, efficiently moving electrons to or from an active reaction site. This is one of its primary functions in batteries and electrochemical test cells.

High Gas Permeability

Directly related to its high porosity, the material has high air and gas permeability. This means gases can flow through it with minimal resistance.

This property is essential for its use as a Gas Diffusion Layer (GDL) in fuel cells, where it must efficiently deliver reactant gases like hydrogen and oxygen to the catalyst layer.

The Role in Electrochemical Systems

The properties of conductivity and permeability work in concert. In a fuel cell, the GDL must do two jobs at once: transport reactant gases to the catalyst and conduct product electrons away from it.

Carbon paper's unique structure is perfectly suited to meet these competing demands.

Understanding the Trade-offs and Handling Considerations

While highly functional, carbon paper is not without its limitations. Its physical characteristics present practical challenges that users must manage.

The Challenge of a Brittle Texture

Carbon paper has a brittle texture, meaning it is rigid and can crack or break easily if bent, flexed, or subjected to sharp impacts.

It requires careful handling during assembly and cannot be used in applications that require material flexibility.

Balancing Porosity and Strength

There is an inherent trade-off between the material's porosity and its mechanical strength. A higher porosity, which improves gas flow, often results in a weaker, more fragile sheet.

Manufacturers carefully control the fiber bonding process to balance these properties for specific end-uses.

Matching Carbon Paper to Your Application

Choosing and using this material effectively comes down to leveraging the right properties for your specific goal.

- If your primary focus is fuel cell development: You will leverage its high gas permeability and conductivity for its role as a Gas Diffusion Layer (GDL).

- If your primary focus is battery research or electrochemistry: Its excellent conductivity and high surface area make it an ideal substrate for creating uniform electrodes.

- If your primary focus is creating composite materials: Its conductive fiber network can be integrated into a non-conductive matrix, but you must design around its inherent brittleness.

Understanding these core properties is the key to effectively utilizing carbon paper in your technical application.

Summary Table:

| Property | Key Characteristic | Primary Function |

|---|---|---|

| Electrical Conductivity | Excellent conductor | Efficient current collection |

| Porosity & Permeability | High void volume | Unobstructed gas/liquid transport |

| Physical Structure | Brittle, uniform thickness | Stable substrate for electrodes |

| Core Material | Non-woven carbon fiber mat | Dual-functionality in electrochemical systems |

Ready to integrate high-performance carbon paper into your research?

KINTEK specializes in premium lab equipment and consumables, including carbon paper ideal for fuel cell development, battery research, and electrochemistry applications. Our materials ensure the high conductivity and porosity your experiments demand.

Contact our experts today to discuss how our carbon paper can enhance your lab's efficiency and results!

Visual Guide

Related Products

- Conductive Carbon Cloth Carbon Paper Carbon Felt for Electrodes and Batteries

- Electrode Polishing Material for Electrochemical Experiments

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- Custom PTFE Teflon Parts Manufacturer for PTFE Ball Valve Seat

People Also Ask

- How should carbon cloth used for high-temperature electrolysis be handled after operation? Prevent Irreversible Oxidative Damage

- What are the common applications for carbon cloth? Unlock Its Potential in Energy & Electrochemical Systems

- What are 3 products that carbon nanotubes can be used in? Enhancing Batteries, Tires, and Composites

- What applications is carbon felt suitable for? Ideal for High-Performance Electrochemical Systems

- What are the four main types of sensors? A Guide to Power Source and Signal Type