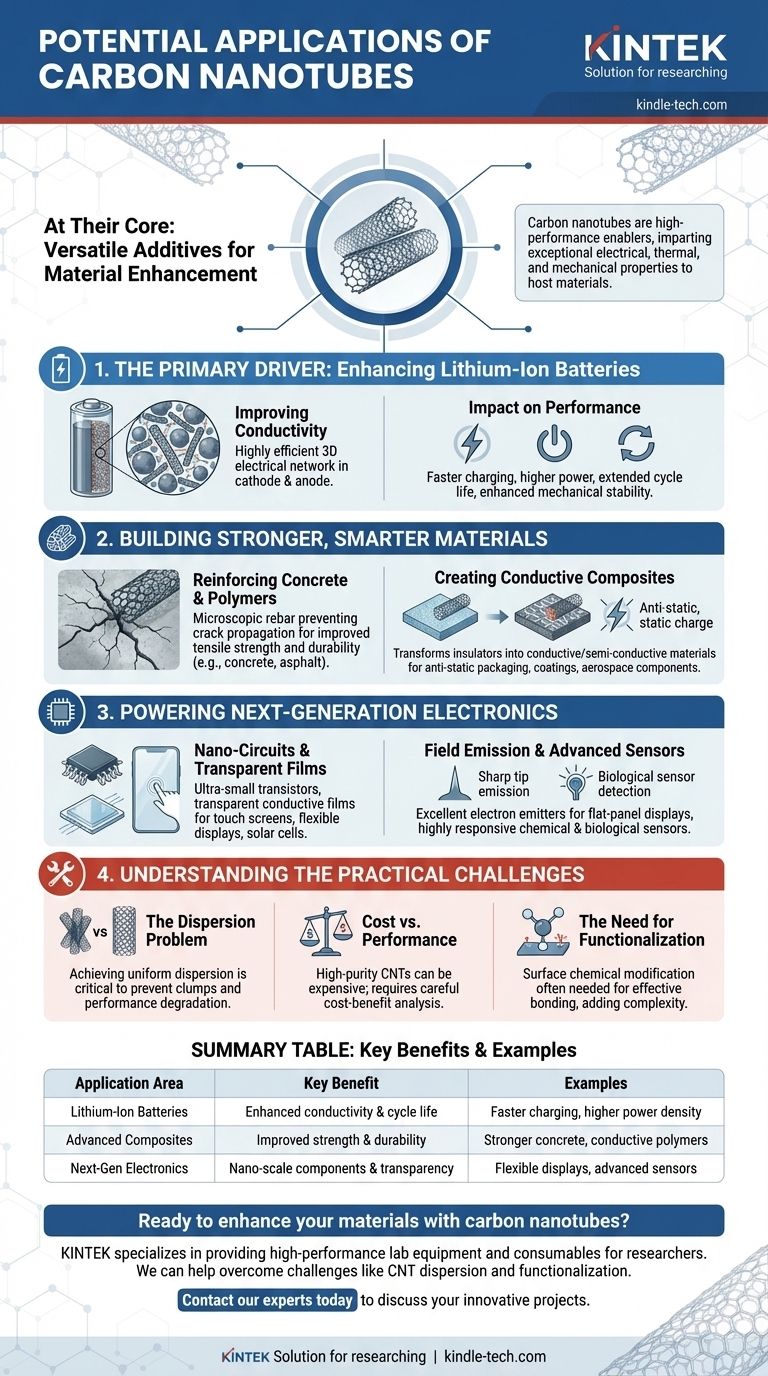

At their core, carbon nanotubes (CNTs) are versatile additives used to enhance the properties of other materials. Their most significant commercial application today is as a conductive additive in lithium-ion batteries, but they are also being integrated into advanced composites, polymers, concrete, and next-generation electronics to improve strength, conductivity, and performance.

Carbon nanotubes are best understood not as standalone products, but as high-performance enablers. Their true value is realized when they are used to impart their exceptional electrical, thermal, and mechanical properties to a host material, solving critical performance bottlenecks.

The Primary Driver: Enhancing Lithium-Ion Batteries

The most mature and high-volume application for CNTs is in energy storage, specifically as a crucial component in lithium-ion batteries.

Improving Cathode and Anode Conductivity

CNTs are added in small quantities to both the cathode and anode materials of a battery. Their extremely high aspect ratio and superior conductivity create a highly efficient, three-dimensional electrical network.

This network allows electrons to move more freely within the electrode, a significant improvement over traditional additives like carbon black.

The Impact on Battery Performance

By improving electrical conductivity, CNTs allow batteries to charge faster and deliver higher power. They also enhance mechanical stability, helping the electrode withstand the physical stress of repeated charging and discharging cycles, which extends the battery's overall lifespan.

Building Stronger, Smarter Materials

CNTs are used as a nano-scale reinforcement and conductive filler, creating a new class of composite materials with enhanced properties.

Reinforcing Concrete and Polymers

When dispersed in materials like concrete, asphalt, or fiber-reinforced polymers, CNTs act like microscopic rebar. They can help prevent the propagation of micro-cracks, leading to materials with significantly improved tensile strength and durability.

Creating Conductive Composites

Many polymers are electrical insulators. Adding CNTs can transform them into conductive or semi-conductive materials. This is critical for applications like anti-static packaging for electronics, conductive coatings, and components for automotive and aerospace that need to dissipate static charge.

Powering Next-Generation Electronics

The unique electronic properties and small size of CNTs make them a candidate for a new wave of electronic devices that go beyond the limits of silicon.

From Nano-Circuits to Transparent Films

Researchers are exploring the use of CNTs to create ultra-small transistors for highly integrated circuits. When deposited as a thin layer, they can also form transparent conductive films, which are essential for touch screens, flexible displays, and solar cells.

Field Emission and Advanced Sensors

CNTs' sharp tips are excellent electron emitters, making them suitable for developing new types of flat-panel displays (field emission displays). Their high surface area and sensitivity also make them ideal for creating highly responsive chemical and biological sensors.

Understanding the Practical Challenges

While incredibly promising, the widespread adoption of CNTs is not without technical hurdles. Understanding these limitations is key to successful implementation.

The Dispersion Problem

By nature, carbon nanotubes tend to clump together due to strong intermolecular forces. Achieving a uniform dispersion within a host material is the single most critical challenge, as clumps can degrade performance and even create weak points.

Cost vs. Performance

Although costs are decreasing as production scales, high-purity CNTs can still be more expensive than the traditional additives they replace. A careful cost-benefit analysis is required to justify their use for a given performance gain.

The Need for Functionalization

To bond effectively with certain host materials, the surface of a CNT often needs to be chemically modified, a process called functionalization. This adds a layer of complexity and cost to the manufacturing process.

How to Evaluate CNTs for Your Application

To determine if carbon nanotubes are the right solution, you must align their properties with your specific performance goal.

- If your primary focus is energy storage: Investigate CNTs as a conductive additive to increase charge rate, power density, and cycle life in battery electrodes.

- If your primary focus is advanced materials: Evaluate CNTs for their ability to add mechanical strength to polymers and concrete or to impart electrical conductivity to insulating materials.

- If your primary focus is next-generation electronics: Explore their potential in applications requiring nano-scale components, transparency, or high sensitivity, such as sensors and transparent films.

Ultimately, leveraging carbon nanotubes successfully depends on matching their unique nanoscale properties to a specific macro-level problem.

Summary Table:

| Application Area | Key Benefit | Examples |

|---|---|---|

| Lithium-Ion Batteries | Enhanced conductivity & cycle life | Faster charging, higher power density |

| Advanced Composites | Improved strength & durability | Stronger concrete, conductive polymers |

| Next-Gen Electronics | Nano-scale components & transparency | Flexible displays, advanced sensors |

Ready to enhance your materials with carbon nanotubes?

KINTEK specializes in providing high-performance lab equipment and consumables for researchers and engineers developing next-generation batteries, composites, and electronics. Our expertise can help you overcome challenges like CNT dispersion and functionalization to achieve your performance goals.

Contact our experts today to discuss how we can support your innovative projects.

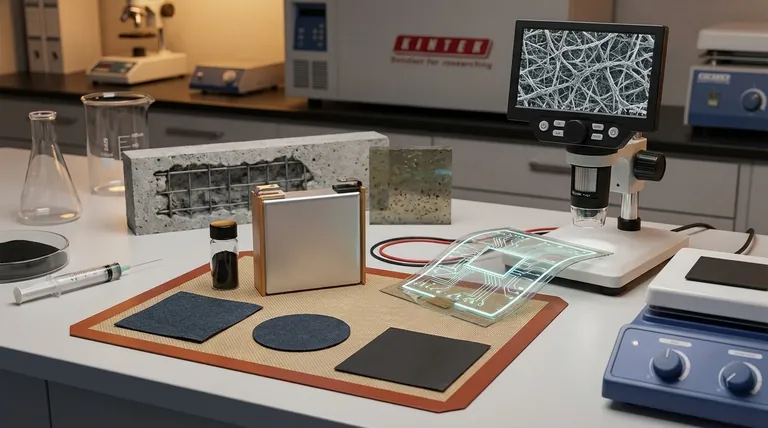

Visual Guide

Related Products

- Conductive Carbon Cloth Carbon Paper Carbon Felt for Electrodes and Batteries

- Aluminum Foil Current Collector for Lithium Battery

- High Purity Zinc Foil for Battery Lab Applications

- Battery Lab Equipment 304 Stainless Steel Strip Foil 20um Thick for Battery Test

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

People Also Ask

- What are 3 products that carbon nanotubes can be used in? Enhancing Batteries, Tires, and Composites

- What applications is carbon felt suitable for? Ideal for High-Performance Electrochemical Systems

- Why are high surface area materials preferred for BES anodes? Maximize Microbial Power and Efficiency

- What are the four main types of sensors? A Guide to Power Source and Signal Type

- What is the ideal operating environment for a glassy carbon sheet? Ensure Optimal Performance and Longevity