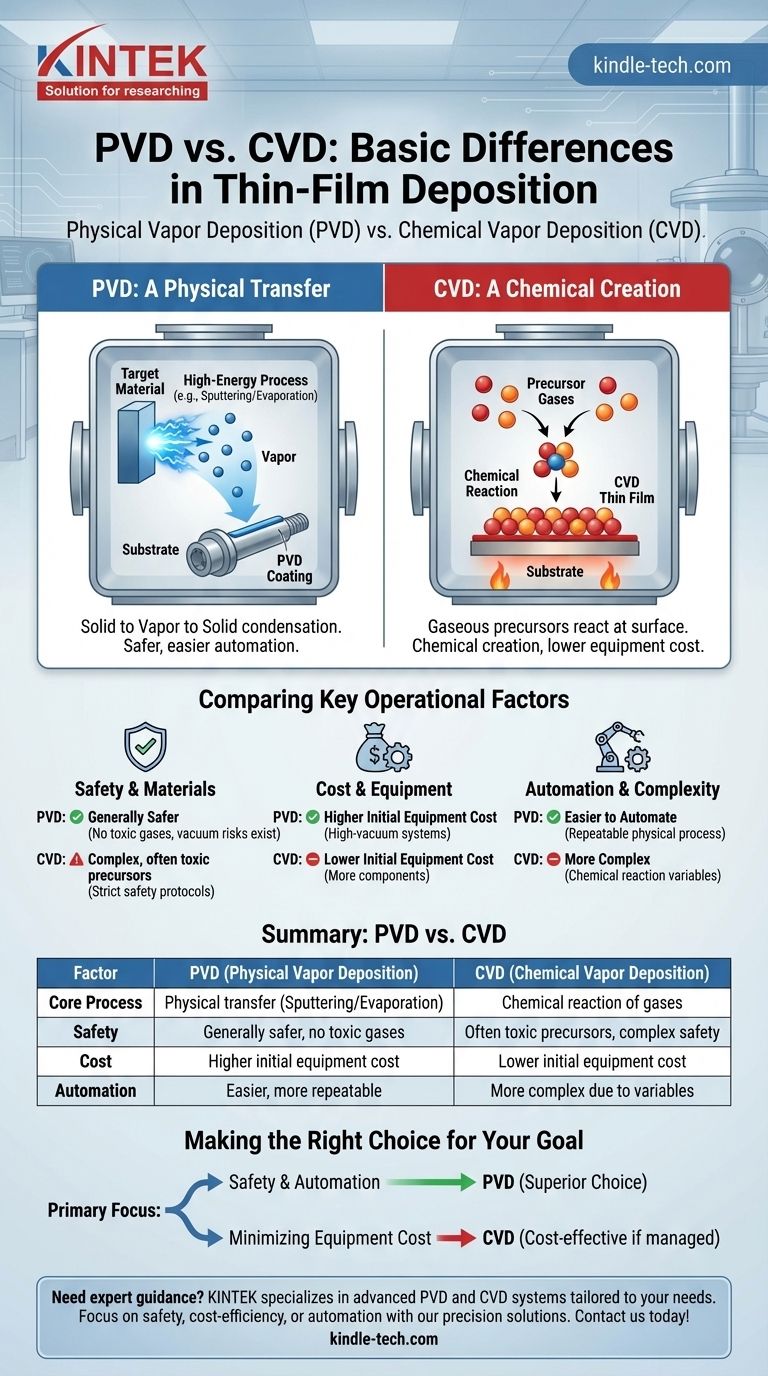

The fundamental difference between PVD and CVD lies in how the coating material arrives at the substrate. Physical Vapor Deposition (PVD) uses physical processes like sputtering or evaporation to transfer a solid or liquid material into a vapor, which then condenses onto the part. In contrast, Chemical Vapor Deposition (CVD) uses chemical reactions between precursor gases at the substrate's surface to create the thin film from entirely new material.

While both PVD and CVD produce a thin, functional film on a substrate, the choice between them hinges on a critical trade-off: PVD is a physical transfer process that is often safer and more easily automated, whereas CVD is a chemical creation process that can be less expensive but involves hazardous materials and complexity.

The Core Process Distinction

Both PVD and CVD are advanced methods for applying thin films, ranging from a few nanometers to several microns, primarily for treating the surfaces of tools and molds. Though they aim for a similar outcome, their underlying mechanisms are entirely different.

PVD: A Physical Transfer

In PVD, the coating material starts in a solid form. High-energy processes within a vacuum chamber dislodge atoms from this source material, turning it into a vapor. This vapor then travels and physically deposits onto the target object, creating a thin, condensed layer.

CVD: A Chemical Creation

CVD is fundamentally a chemical process. It introduces reactive gases into a chamber containing the substrate. When these gases come into contact with the heated substrate, a chemical reaction is triggered, causing a solid material to form and deposit directly onto the surface.

Comparing Key Operational Factors

Understanding the practical differences in safety, cost, and complexity is essential when evaluating these two technologies for a specific application.

Safety and Materials

CVD can be complex and often involves the use of toxic or harmful precursor chemicals. This necessitates robust safety protocols and specialized handling procedures.

In contrast, PVD is generally considered a safer process as it does not rely on toxic gases. However, it still carries risks, such as the potential for explosion if the high-vacuum chamber is not ventilated properly.

Cost and Equipment

The initial investment for these technologies often differs significantly. PVD is typically more expensive than CVD due to the need for specialized high-vacuum chambers and related equipment.

Both processes require a variety of sophisticated components, including valves, sensors, and temperature control units to manage the deposition environment precisely.

Automation and Complexity

PVD coatings can be more easily automated than CVD coatings. The physical nature of the process lends itself to more straightforward control and repeatability in automated production lines.

CVD's reliance on managing precise chemical reactions can introduce more variables, making automation a more complex challenge.

Making the Right Choice for Your Goal

Selecting the correct process requires aligning the technology's strengths with your project's primary constraints and objectives.

- If your primary focus is safety and automation: PVD is often the superior choice due to its lack of toxic precursor gases and its suitability for automated systems.

- If your primary focus is minimizing equipment cost: CVD may be a more cost-effective option, provided you have the infrastructure and expertise to safely manage the associated chemical processes.

Ultimately, choosing the right deposition method depends on a clear understanding of your application's specific technical, safety, and budgetary requirements.

Summary Table:

| Factor | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Core Process | Physical transfer of material via sputtering/evaporation | Chemical reaction of gases at the substrate surface |

| Safety | Generally safer; no toxic gases (but vacuum risks exist) | Often involves toxic precursors; requires strict safety protocols |

| Cost | Higher initial equipment cost (high-vacuum systems) | Lower initial equipment cost |

| Automation | Easier to automate; more repeatable | More complex automation due to chemical variables |

| Best For | Applications prioritizing safety and automation | Applications focused on cost-effectiveness with proper safety measures |

Need expert guidance on selecting the right deposition process for your lab? At KINTEK, we specialize in providing high-quality lab equipment and consumables, including advanced PVD and CVD systems tailored to your specific research or production needs. Whether you're focused on safety, cost-efficiency, or automation, our solutions ensure precision, reliability, and enhanced performance for your laboratory workflows. Contact us today to discuss how we can support your thin-film deposition requirements!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the difference between CVD and PECVD? Choose the Right Thin-Film Deposition Method

- What are the examples of CVD method? Discover the Versatile Applications of Chemical Vapor Deposition

- What are the advantages of PECVD over CVD? Achieve High-Quality Thin Films at Lower Temperatures

- What is the difference between CVD and PVD process? A Guide to Choosing the Right Coating Method

- How plasma is generated in PECVD? A Step-by-Step Breakdown of the Process