At its core, induction melting is a process that uses powerful, high-frequency electromagnetic fields to heat and melt conductive metals. Unlike a traditional furnace that heats from the outside, an induction coil generates electrical currents directly within the metal itself, causing it to melt rapidly and cleanly from the inside out.

The fundamental advantage of induction melting is its ability to transfer energy directly into the material being melted. This makes it a fast, efficient, and highly controllable process that includes a natural stirring action, ensuring a uniform and high-quality final product.

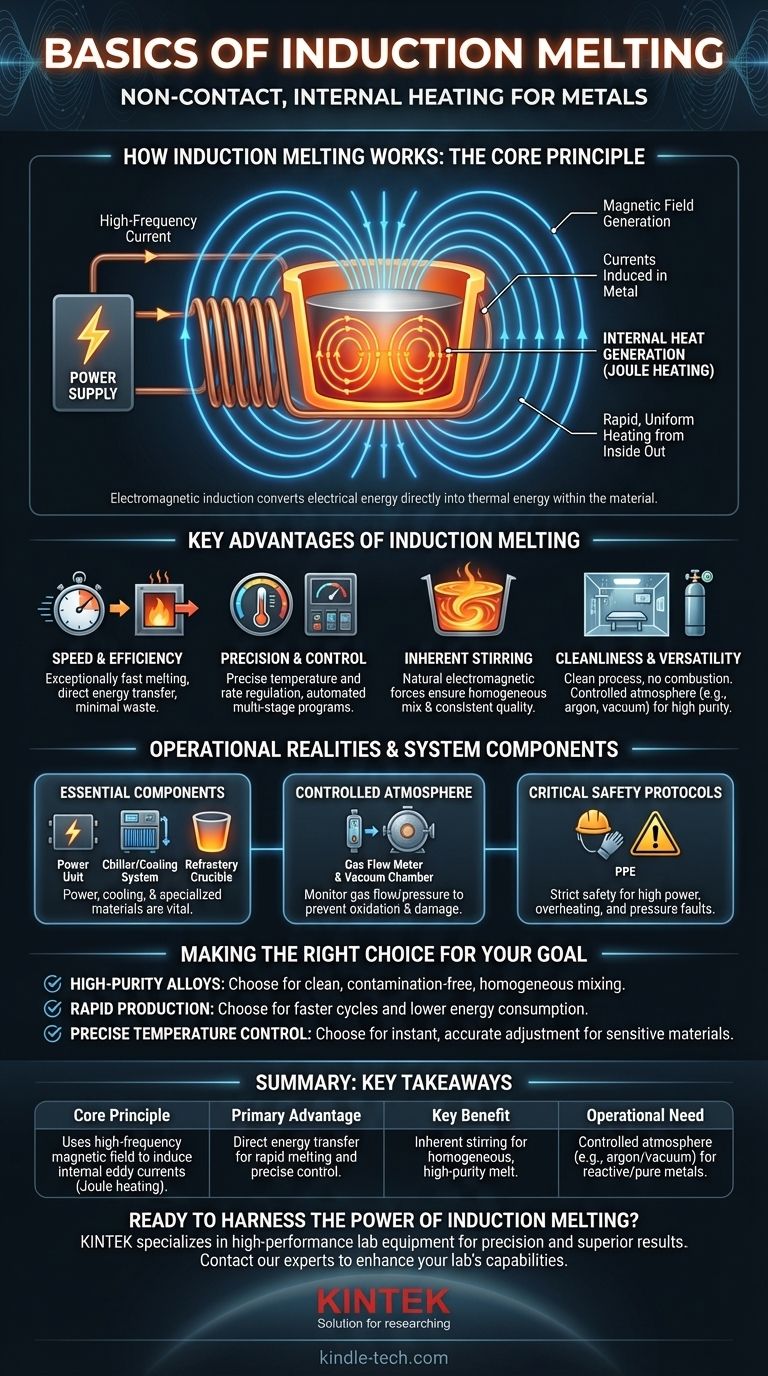

How Induction Melting Works: The Core Principle

Induction melting is based on the principles of electromagnetism. It's a non-contact heating method that converts electrical energy into thermal energy within the target material.

The Electromagnetic Coil

The process begins with a powerful power supply that sends a high-frequency alternating current through a copper induction coil. This coil, typically shaped to surround the crucible holding the metal, generates a strong and rapidly changing magnetic field.

Inducing Current in the Metal

When a conductive material, such as steel or other metals, is placed within this magnetic field, the field induces low-voltage, high-amperage electrical currents (known as eddy currents) within the metal itself. The metal effectively becomes the secondary coil in a transformer circuit.

Internal Heat Generation

The metal's natural resistance to the flow of these eddy currents generates immense heat. This phenomenon, known as Joule heating, causes the material's temperature to rise rapidly and uniformly, leading to an efficient and controlled melt without any external flame or heating element.

The Key Advantages of This Method

The unique principle behind induction melting offers several significant operational benefits over traditional methods.

Speed and Efficiency

Because heat is generated directly within the charge material, very little energy is wasted heating the surrounding furnace structure. This direct energy transfer results in exceptionally fast melting times and high overall energy efficiency.

Precision and Control

The amount of heat generated is directly proportional to the power supplied to the coil. Modern power units allow for precise control over the melting temperature and rate, which is critical for meeting specific metallurgical requirements. Systems often use a PID temperature controller for automated, multi-stage programs.

Inherent Stirring for Homogeneity

The powerful electromagnetic forces at play create a natural stirring or mixing effect within the molten metal bath. This "inductive stirring" ensures a completely homogeneous mix, which is invaluable when creating alloys or ensuring consistent material quality.

Cleanliness and Versatility

Induction melting is an exceptionally clean process, as there is no combustion or contact with heating elements that could introduce impurities. The process can be performed in a controlled atmosphere, such as under a vacuum or with an inert gas like flowing argon, to produce extremely high-purity metals.

Understanding the Operational Realities

While powerful, induction melting systems require careful management of their components and operational environment to ensure safety and longevity.

Essential System Components

A complete induction system consists of more than just the furnace. Core components include the power unit that provides the high-frequency current, a chiller or water-cooling system to protect the coil from overheating, and the furnace body or crucible made from refractory materials that can withstand extreme temperatures.

The Need for a Controlled Atmosphere

For reactive metals or high-purity applications, maintaining a specific atmosphere is critical. Operators must carefully monitor gas flow rates and pressure within the furnace chamber to prevent oxidation and avoid equipment damage, such as a quartz tube cracking under improper pressure.

Critical Safety Protocols

Operating an induction furnace demands strict adherence to safety protocols. This includes the use of personal protective equipment and reliance on the system's built-in protection for overheating, high power, and water pressure faults. Operators must be thoroughly trained to manage the process safely.

Making the Right Choice for Your Goal

Selecting a melting technology depends entirely on your project's specific priorities, from purity and speed to the type of material being processed.

- If your primary focus is high-purity alloys: The clean, non-contact heating and inherent stirring of induction melting make it the superior choice for preventing contamination and ensuring a homogeneous mix.

- If your primary focus is rapid production and efficiency: The direct energy transfer of induction offers faster melt cycles and lower energy consumption compared to most fuel-fired or resistance furnaces.

- If your primary focus is precise temperature control: The ability to instantly and accurately adjust power provides unparalleled control over the melting process, which is critical for complex or sensitive materials.

Ultimately, understanding these core principles empowers you to determine if induction melting's unique combination of speed, control, and cleanliness aligns with your specific metallurgical goals.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Core Principle | Uses a high-frequency magnetic field to induce electrical currents (eddy currents) directly inside the metal, generating heat internally (Joule heating). |

| Primary Advantage | Direct energy transfer for rapid melting, high efficiency, and precise temperature control. |

| Key Benefit | Inherent stirring action ensures a homogeneous melt, ideal for alloys and high-purity applications. |

| Operational Need | Requires a controlled atmosphere (e.g., argon or vacuum) for reactive metals and high-purity goals. |

Ready to harness the power of induction melting for your lab?

KINTEK specializes in high-performance lab equipment, including induction melting systems designed for precision, efficiency, and superior results. Whether your focus is on creating high-purity alloys, accelerating R&D, or achieving exacting temperature control, our solutions are engineered to meet your specific metallurgical goals.

Contact our experts today to discuss how an induction melting furnace from KINTEK can enhance your laboratory's capabilities and drive your projects forward.

Visual Guide

Related Products

- Non Consumable Vacuum Arc Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

People Also Ask

- How does vacuum arc melting equipment facilitate Ti-Cr-Al-Nb alloy prep? Precision High-Temp Melting Explained

- What is the primary function of a vacuum arc melting furnace in RHEA preparation? Achieving Extreme Thermal Fusion

- What is the role of a laboratory vacuum arc remelting furnace? Mastering High-Entropy Alloy Synthesis

- What are the advantages and disadvantages of brazing? A Guide to Strong, Clean Metal Joining

- What is AC frame? Decoding the Two Meanings in Wi-Fi and Video