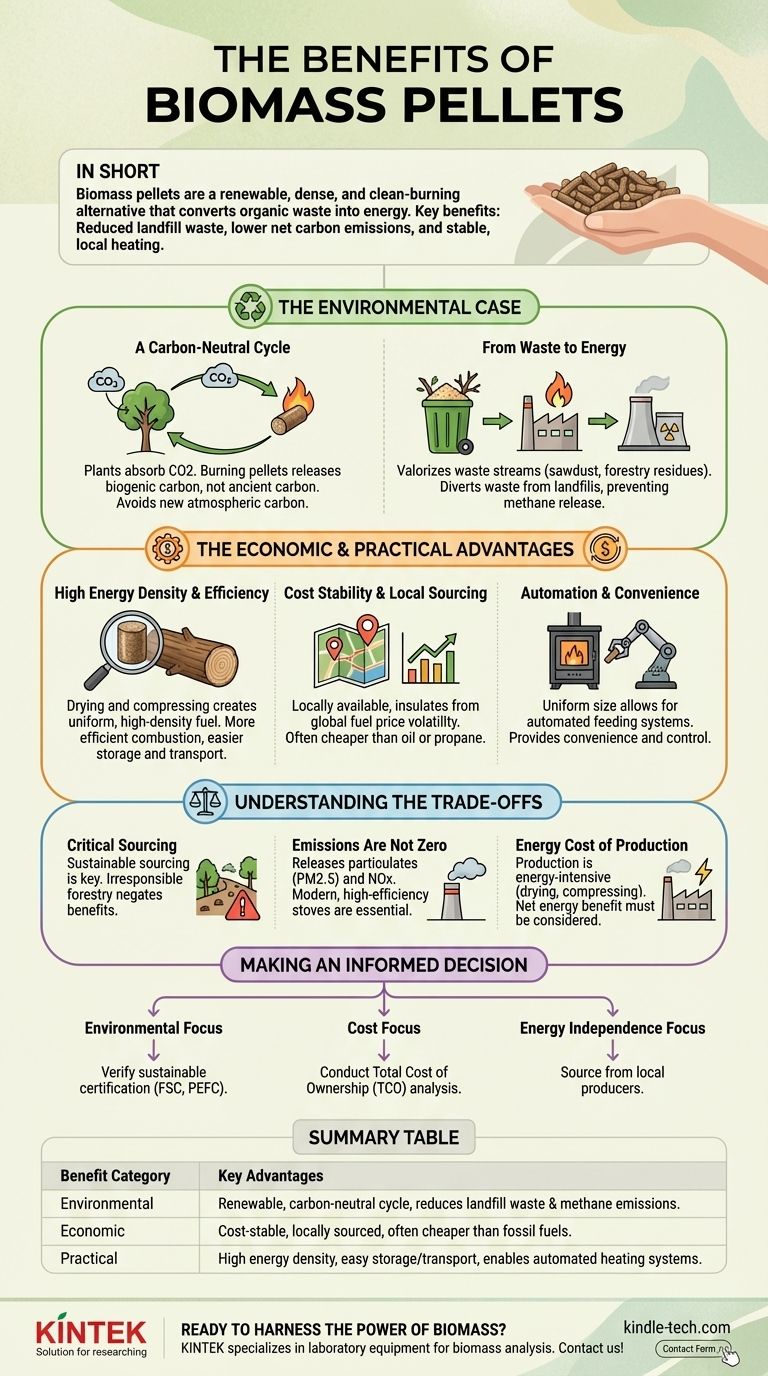

In short, biomass pellets offer a renewable energy alternative that converts organic waste into a dense, clean-burning, and economically viable fuel source. Their primary benefits stem from their potential to reduce landfill waste, lower net carbon emissions compared to fossil fuels, and provide a stable, locally-sourced heating option for both homes and industrial facilities.

Biomass pellets are not just a fuel; they represent a strategy for revaluing waste. By compacting organic materials, they create an energy-dense product that is easier to store, transport, and burn efficiently than its raw counterparts.

The Environmental Case for Biomass Pellets

The most frequently cited benefit of biomass pellets is their improved environmental profile when compared directly against fossil fuels like coal or heating oil.

A Carbon-Neutral Cycle

Unlike fossil fuels, which release ancient carbon into the atmosphere, biomass is part of the current biogenic carbon cycle. Plants absorb CO2 as they grow, and burning pellets made from that plant matter releases the same CO2 back into the atmosphere, creating a theoretically closed loop.

This cycle helps avoid the addition of new carbon to the atmosphere, which is the primary driver of climate change.

From Waste to Energy

A significant advantage of biomass pellets is their ability to valorize waste streams. They are often produced from sawdust, forestry residues, agricultural leftovers, and other organic byproducts.

By converting this material into fuel, the process diverts immense volumes of waste from landfills, where its decomposition would otherwise release methane—a potent greenhouse gas.

The Economic and Practical Advantages

Beyond the environmental arguments, biomass pellets provide tangible benefits in terms of cost, stability, and ease of use.

High Energy Density and Efficiency

The pelletization process—drying, grinding, and compressing biomass—creates a fuel with high density and low moisture content. This uniformity makes it much more efficient to burn than raw logs or wood chips.

This density also simplifies logistics. It is cheaper and easier to transport and store a given amount of energy in pellet form than in its original, bulky biomass state.

Cost Stability and Local Sourcing

Biomass is a locally available resource. This can insulate users from the price volatility and geopolitical instability associated with the global fossil fuel market.

While upfront equipment costs can be high, the fuel itself is often cheaper and more predictable in price than heating oil or propane in many regions.

Automation and Convenience

The uniform size and shape of pellets are a key practical benefit. This consistency allows for automated feeding systems in pellet stoves and boilers, providing a level of convenience and control that is impossible with traditional wood-burning stoves.

Understanding the Trade-offs

While the benefits are compelling, a complete analysis requires acknowledging the limitations and potential downsides. True sustainability depends entirely on responsible management.

The Critical Role of Sourcing

The environmental case for biomass collapses if the raw material is not sourced sustainably. Using waste wood is ideal, but sourcing pellets from irresponsibly managed forests contributes to deforestation and habitat loss, negating the carbon benefits.

Emissions Are Not Zero

While "carbon neutral" in theory, burning any solid fuel releases particulates (PM2.5) and other pollutants like nitrogen oxides (NOx). Modern, high-efficiency pellet stoves with proper filtration are essential to minimize local air quality impact.

The Energy Cost of Production

Creating pellets is an energy-intensive process. The biomass must be collected, transported, dried, and compressed. This energy input, which often relies on fossil fuels, must be subtracted from the total energy gain to understand the true "net energy" benefit.

Making an Informed Decision

Your choice to use biomass pellets should be aligned with your specific goals, whether they are environmental, economic, or logistical.

- If your primary focus is environmental impact: Verify your fuel supply is certified by a reputable third party (like the Forest Stewardship Council or the Programme for the Endorsement of Forest Certification) to ensure it comes from sustainable waste or forestry.

- If your primary focus is cost savings: Conduct a total cost of ownership analysis, factoring in the price of the pellet stove or boiler, installation, and the local cost and availability of pellets versus your current heating fuel.

- If your primary focus is energy independence: Sourcing pellets from a local producer provides a hedge against global energy price shocks and supports your regional economy.

Ultimately, biomass pellets are a powerful tool for converting distributed, low-value waste into a centralized, high-value energy source.

Summary Table:

| Benefit Category | Key Advantages |

|---|---|

| Environmental | Renewable, carbon-neutral cycle, reduces landfill waste & methane emissions. |

| Economic | Cost-stable, locally sourced, often cheaper than fossil fuels. |

| Practical | High energy density, easy storage/transport, enables automated heating systems. |

Ready to harness the power of biomass for your energy needs?

KINTEK specializes in providing high-quality laboratory equipment and consumables essential for analyzing and developing biomass feedstocks and pellet fuels. Whether you are a researcher optimizing pellet composition or an industrial producer ensuring quality control, our solutions support your work in sustainable energy.

Contact our experts today via our Contact Form to discuss how KINTEK can equip your lab for success in the bioenergy sector.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What are the different types of pyrolysis machines? Choose the Right System for Your Output