Controlled atmosphere furnace brazing is a manufacturing process that provides exceptionally clean, strong, and precise joints by heating components in a chemically controlled environment. This method largely eliminates the need for corrosive fluxes and subsequent cleaning, minimizes part distortion, and is highly efficient for joining complex or dissimilar materials in high-volume production.

The fundamental advantage of furnace brazing is not just the application of heat, but the precise control over the entire thermal and chemical environment. This transforms metal joining from a variable, manual craft into a highly repeatable, automated science, delivering superior quality and economic efficiency.

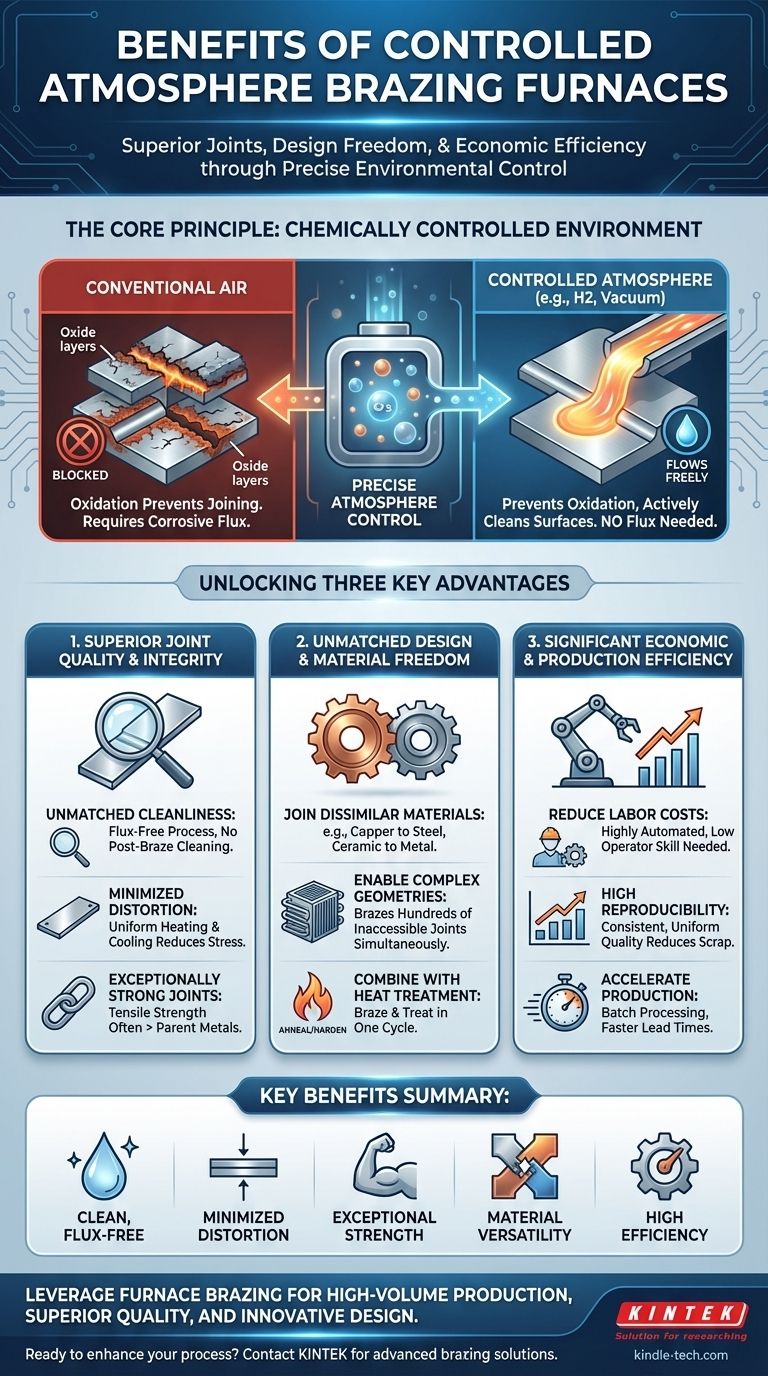

The Core Principle: A Chemically Controlled Environment

The "controlled atmosphere" is the key to this process's success. By replacing the normal air inside the furnace with a specific gas mixture, we can prevent and even reverse the oxidation that typically hinders metal joining.

Preventing Oxidation

Most brazing issues stem from oxides that form on the surface of the parent metals when heated. These oxides prevent the molten braze alloy from wetting and flowing into the joint.

A controlled atmosphere furnace displaces the oxygen with a neutral or active gas, creating an oxygen-free environment that prevents these oxides from forming in the first place.

Actively Cleaning the Metal

Some atmospheres go a step further. Gases like hydrogen (H2) act as an active agent, chemically reacting with and reducing any pre-existing metal oxides on the parts.

This leaves the parent metal surfaces perfectly clean at the atomic level, ensuring the braze alloy can form a strong, seamless metallurgical bond.

Unlocking Superior Joint Quality and Integrity

This precise environmental control translates directly into higher-quality finished products. The process is defined by its ability to produce joints that are often superior to the parent materials themselves.

Achieving Unmatched Cleanliness

Because the atmosphere prevents oxidation, the need for corrosive chemical fluxes is often eliminated. This is a significant benefit.

It means no entrapped flux in the final joint, which can cause corrosion, and it removes the costly and time-consuming step of post-braze cleaning.

Minimizing Thermal Distortion

Furnace brazing provides uniform heating and cooling. The entire assembly is brought to temperature slowly and evenly, and cooled in the same controlled manner.

This drastically reduces the residual stresses and thermal distortion common with localized heating methods like torch brazing or welding, making it ideal for high-precision assemblies.

Creating Exceptionally Strong Joints

The process allows the braze alloy to flow into tight-fitting joints through capillary action, creating a bond with tensile strength often greater than the parent metals.

Because the parent metals are never melted, their inherent properties are not compromised, and the joint is free from the stress concentrations that can occur in welds.

Gaining Unmatched Design and Material Freedom

Furnace brazing removes many of the constraints found in other joining methods, giving engineers and designers far greater flexibility.

Joining Dissimilar and Unweldable Materials

The process excels at joining dissimilar materials, such as copper to steel or even non-metals like ceramics to metal. It also allows for the joining of materials that are considered "unweldable."

Enabling Complex Geometries

Assemblies with hundreds of joints, or with joints that are long and inaccessible, can be brazed simultaneously in a single furnace cycle.

This makes it possible to manufacture highly complex components, such as heat exchangers, that would be impractical or impossible to create with other methods.

Combining Brazing with Heat Treatment

The controlled heating and cooling cycles can be engineered to combine heat treatments with the brazing process.

For example, a part can be brazed and simultaneously annealed, hardened, or stress-relieved in a single operation, saving significant time and cost.

Understanding the Trade-offs and Process Considerations

While powerful, furnace brazing is not the solution for every application. Objectivity requires acknowledging its limitations.

High Initial Capital Cost

Industrial-grade controlled atmosphere furnaces represent a significant capital investment compared to manual brazing stations.

Batch Processing Nature

Furnace brazing is a batch process. While ideal for high volumes of identical parts, it is less efficient for one-off repairs or single-piece prototyping where speed is the primary concern.

Process Design Expertise

Success depends on careful process engineering. Selecting the correct braze alloy, joint design, furnace cycle, and atmosphere composition requires significant technical expertise.

Achieving Significant Economic and Production Efficiency

For the right application, furnace brazing delivers substantial economic benefits, particularly in mass production environments.

Reducing Labor Costs

The process is highly automated and does not require the skilled labor associated with manual welding or torch brazing. A single operator can often manage the production of thousands of joints.

Ensuring High Reproducibility

Once the process parameters are set, furnace brazing delivers extremely consistent and reproducible results. This reduces scrap rates and ensures uniform quality across an entire production run.

Accelerating Production Time

The ability to create multiple joints in a single cycle and eliminate post-braze cleaning dramatically speeds up lead times for complex assemblies in a mass production setting.

How to Leverage Furnace Brazing for Your Goal

By understanding the core strengths of the process, you can align its capabilities with your specific manufacturing objectives.

- If your primary focus is high-volume production: Leverage the process for its unmatched repeatability, low operator skill requirements, and overall cost-effectiveness at scale.

- If your primary focus is product quality and performance: Utilize the uniform heating and clean atmosphere to produce strong, distortion-free joints that enhance product reliability and lifespan.

- If your primary focus is design innovation: Embrace the freedom to join dissimilar materials and create complex, multi-joint assemblies that are not feasible with other methods.

By controlling the entire environment, furnace brazing provides a powerful and reliable solution for manufacturing the next generation of high-performance components.

Summary Table:

| Key Benefit | Description |

|---|---|

| Clean, Flux-Free Joints | Eliminates corrosive fluxes and post-braze cleaning by preventing oxidation in an oxygen-free environment. |

| Minimized Distortion | Uniform heating and cooling reduces thermal stress and part distortion for high-precision assemblies. |

| Exceptional Joint Strength | Creates bonds with tensile strength often greater than the parent metals through capillary action. |

| Material Versatility | Joins dissimilar or unweldable materials (e.g., copper to steel, ceramics to metal) with ease. |

| High Production Efficiency | Automated process ideal for high-volume production, reducing labor costs and accelerating lead times. |

Ready to enhance your manufacturing process with controlled atmosphere brazing?

At KINTEK, we specialize in providing advanced lab equipment and consumables, including brazing solutions tailored to your laboratory and production needs. Whether you're focused on high-volume production, superior joint quality, or innovative material designs, our expertise ensures you achieve clean, strong, and efficient results.

Contact us today to discuss how our brazing furnaces can transform your metal joining capabilities!

Visual Guide

Related Products

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

People Also Ask

- What gases are used in inert atmospheres? Choose the Right Gas for Non-Reactive Environments

- Can nitrogen gas be heated? Leverage Inert Heat for Precision and Safety

- Why nitrogen is used in furnace? A Cost-Effective Shield for High-Temperature Processes

- How we can develop inert atmosphere for a chemical reaction? Master Precise Atmospheric Control for Your Lab

- Can nitrogen be used for brazing? Key Conditions and Applications Explained