At its core, cryogenic machining uses extreme cold to fundamentally improve the cutting process, resulting in significantly longer tool life, a superior surface finish on the workpiece, and higher overall productivity. By using a coolant like liquid nitrogen, it effectively eliminates the primary obstacle in high-performance machining: excessive heat generation at the cutting zone.

The central advantage of cryogenic machining is its ability to control heat. This control makes hard-to-machine materials more brittle and easier to cut, which prevents thermal damage, reduces tool wear, and ultimately leads to a more efficient and precise manufacturing process.

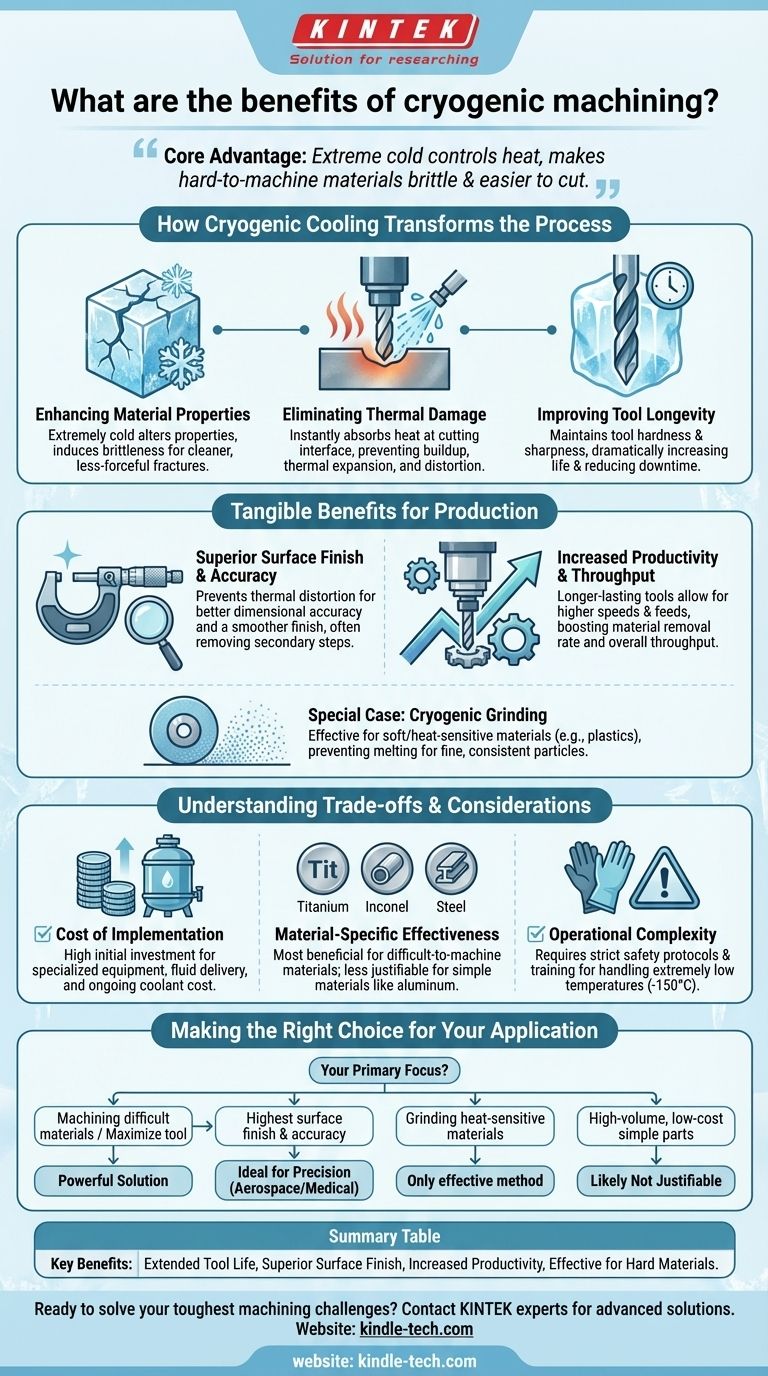

How Cryogenic Cooling Transforms the Machining Process

Traditional machining generates intense friction and heat, which can deform the workpiece, damage the cutting tool, and compromise the final product. Cryogenic cooling directly counteracts these issues at their source.

Enhancing Material Properties

The extreme cold temporarily alters the physical properties of the material being machined. This makes it more brittle and less ductile.

This induced brittleness allows the material to fracture cleanly as a chip, rather than deforming plastically. This results in more perfect chip handling and less force required for the cut.

Eliminating Thermal Damage

The primary role of the cryogenic coolant is to absorb and remove heat from the cutting interface instantly. This keeps both the tool and the workpiece at or near ambient temperature.

By preventing heat buildup, you avoid common problems like thermal expansion, micro-structural damage, and the formation of a heat-affected zone on the part's surface.

Improving Tool Longevity

Heat is the number one enemy of a cutting tool. The high temperatures of conventional machining soften the tool's cutting edge, leading to rapid wear and failure.

Cryogenic cooling maintains the tool's hardness and sharpness for a much longer period. This dramatically improves tool life, reducing the frequency of tool changes, machine downtime, and overall production cost.

Tangible Benefits for Production Quality and Efficiency

These fundamental process improvements translate directly into measurable gains in quality, speed, and cost-effectiveness.

Superior Surface Finish and Accuracy

Because cryogenic machining prevents thermal expansion and workpiece distortion, it enables better dimensional accuracy. The clean, brittle cutting action also produces a much smoother surface finish, often reducing the need for secondary finishing operations.

Increased Productivity and Throughput

With tools that last longer and cut more effectively, machines can be run at higher speeds and feeds. This increases the material removal rate and overall throughput without sacrificing quality. Furthermore, some processes see lower energy consumption due to reduced cutting forces.

The Specific Case of Cryogenic Grinding

Cryogenic principles are particularly effective in grinding, especially for soft, tough, or heat-sensitive materials like plastics, spices, or pharmaceuticals.

The cold makes the materials brittle, allowing them to be milled into extremely fine, uniform particles. It also prevents the material from melting or caking inside the grinding mill, which increases yield and simplifies equipment cleanup.

Understanding the Trade-offs and Considerations

While the benefits are significant, cryogenic machining is not a universal solution. A clear-eyed assessment of its challenges is critical for successful implementation.

The Cost of Implementation

The primary barrier is the initial investment. This includes specialized equipment for storing and delivering the cryogenic fluid (e.g., liquid nitrogen) and retrofitting machine tools with insulated lines and nozzles. The ongoing cost of the coolant itself must also be factored into the operational budget.

Material-Specific Effectiveness

The advantages of cryogenic cooling are most pronounced on materials that are difficult to machine conventionally. This includes titanium alloys, nickel-based superalloys (like Inconel), hardened steels, and composites. For simpler materials like aluminum or low-carbon steel, the benefits may not justify the added cost and complexity.

Operational Complexity

Working with cryogenic fluids requires strict safety protocols and specialized training. Handling substances at temperatures below -150°C (-238°F) introduces risks that are not present in traditional machining environments.

Making the Right Choice for Your Application

Ultimately, the decision to adopt cryogenic machining depends entirely on your specific manufacturing goals and challenges.

- If your primary focus is machining difficult materials or maximizing tool life: Cryogenic cooling is a powerful solution that can make previously challenging jobs viable and highly profitable.

- If your primary focus is achieving the highest possible surface finish and dimensional accuracy: The elimination of thermal distortion makes this an ideal technology for precision components in aerospace, medical, and defense.

- If your primary focus is grinding heat-sensitive or soft materials: Cryogenic grinding is often the only effective method to achieve fine, consistent particle sizes without damaging the product.

- If your primary focus is high-volume, low-cost production of simple parts: The economic and logistical overhead of a cryogenic system may not be justifiable compared to optimized conventional cooling methods.

By understanding its core principles and practical trade-offs, you can determine if this advanced manufacturing technique is the right tool to solve your specific challenges.

Summary Table:

| Key Benefit | Description |

|---|---|

| Extended Tool Life | Reduces tool wear by eliminating heat, the primary cause of failure. |

| Superior Surface Finish | Prevents thermal damage, enabling better accuracy and smoother finishes. |

| Increased Productivity | Allows for higher cutting speeds and feeds, boosting throughput. |

| Effective for Hard Materials | Ideal for titanium, Inconel, and hardened steels. |

Ready to solve your toughest machining challenges?

At KINTEK, we specialize in providing advanced laboratory and manufacturing equipment, including solutions for precision machining and material processing. If you're working with hard-to-machine alloys or require superior surface finishes, our expertise can help you implement the right technology to boost your productivity and quality.

Contact our experts today to discuss how we can support your specific laboratory and production needs!

Visual Guide

Related Products

- High Performance Laboratory Freeze Dryer for Research and Development

- High Performance Laboratory Freeze Dryer

- Cylindrical Press Mold for Lab Applications

- Assemble Lab Cylindrical Press Mold

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- Why use a laboratory freeze dryer for microalgae? Preserve Sample Integrity for Accurate Analysis

- Why is a freeze dryer used for metagenomic analysis on sludge? Ensure Genomic Integrity for Accurate Profiling

- Why is a laboratory vacuum freeze dryer essential for plant extracts? Preserve Bioactivity & Structure

- How does the use of a vacuum freeze dryer benefit cys-CDs powder preparation? Preserve Nanoparticle Integrity

- Why is a freeze dryer preferred over thermal drying for Fe-ZTA cermets? Ensure Pure, Homogeneous Slurry Processing