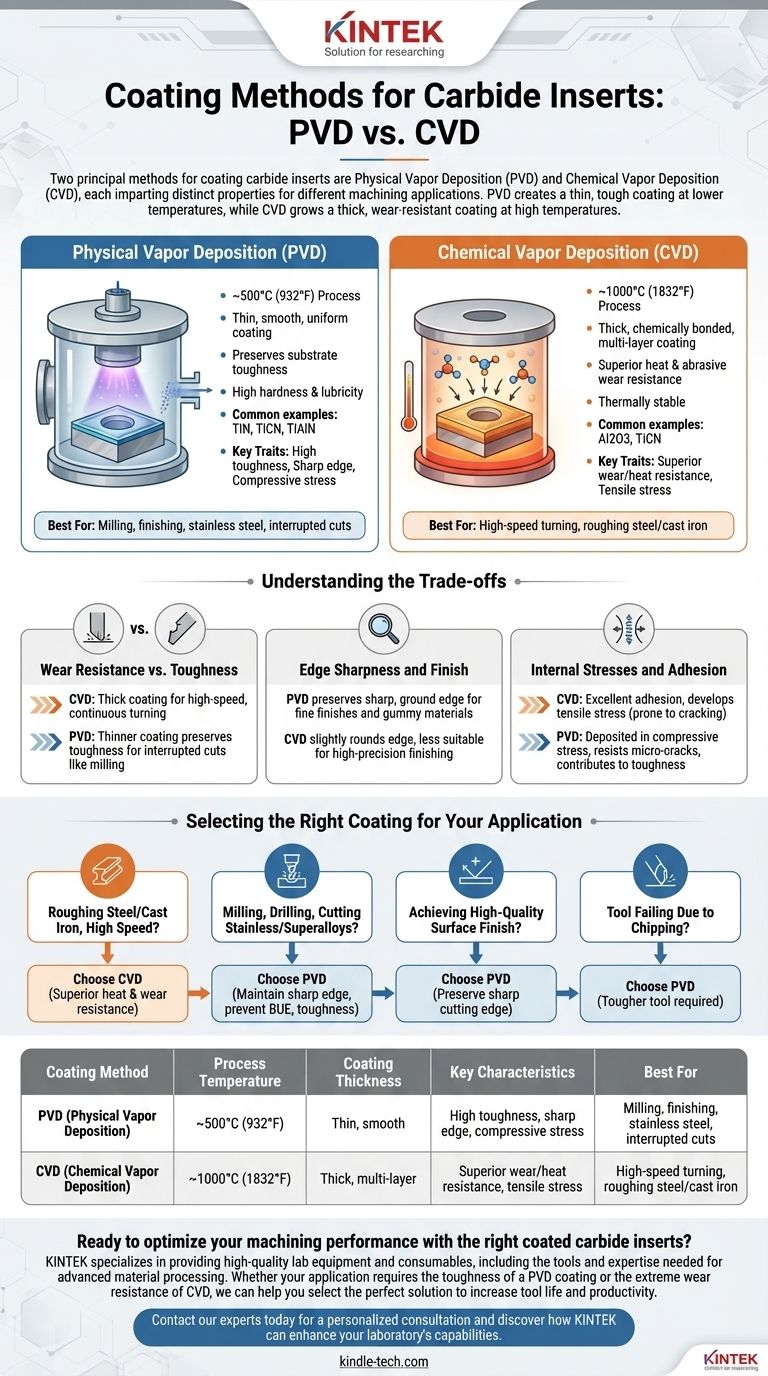

In short, the two principal methods for coating carbide inserts are Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD). Each process imparts distinct properties to the insert, making them suitable for very different machining applications. PVD is a lower-temperature process that creates a thin, tough coating, while CVD uses high temperatures to grow a thick, highly wear-resistant coating.

The choice between coating methods is not about which is "better," but which provides the right balance of wear resistance and toughness for your specific job. PVD excels where edge sharpness and toughness are critical, whereas CVD dominates in high-heat, abrasive applications.

A Tale of Two Technologies: PVD vs. CVD

To select the right tool, you must understand how the coating is applied. The manufacturing process itself dictates the performance characteristics of the final insert.

Physical Vapor Deposition (PVD)

PVD is a lower-temperature process, typically conducted around 500°C (932°F). In a vacuum chamber, a solid coating material is vaporized into a plasma and then physically deposited onto the carbide insert's surface.

This method results in an extremely thin, smooth, and uniform coating. Because the temperature is relatively low, it does not significantly alter the properties of the underlying carbide substrate, preserving its inherent toughness.

PVD coatings are known for their high hardness and lubricity. Common examples include Titanium Nitride (TiN), Titanium Carbonitride (TiCN), and Titanium Aluminum Nitride (TiAlN).

Chemical Vapor Deposition (CVD)

CVD is a high-temperature process, often operating near 1000°C (1832°F). It involves a chemical reaction where gaseous precursor molecules react on the surface of the heated insert, "growing" a new layer of material.

This process creates a much thicker and more chemically bonded coating than PVD. The resulting layers are exceptionally hard and thermally stable, providing a superior barrier against heat and abrasive wear.

The most common CVD coatings are multi-layered, frequently including a thick layer of Aluminum Oxide (Al2O3) for thermal protection and Titanium Carbonitride (TiCN) for wear resistance.

Understanding the Trade-offs

The differences in the application process lead to a direct trade-off between key performance characteristics. Understanding this is central to tool selection.

Wear Resistance vs. Toughness

A thick CVD coating provides an exceptional thermal barrier and resistance to abrasive wear, making it ideal for high-speed cutting in predictable, continuous operations like turning steel.

However, the high application temperature can reduce the substrate's toughness. The thinner PVD coating preserves the substrate's toughness, making it far superior for resisting the chipping and cracking common in interrupted cuts, such as milling.

Edge Sharpness and Finish

PVD's low-temperature process perfectly preserves the sharp, ground edge of the insert. This is critical for achieving a fine surface finish and for cleanly shearing "gummy" materials like aluminum, stainless steel, and superalloys without creating a built-up edge (BUE).

The high heat of the CVD process tends to slightly round the cutting edge. While not an issue for roughing, this makes it less suitable for high-precision finishing operations.

Internal Stresses and Adhesion

CVD coatings have excellent chemical adhesion to the substrate. However, as they cool from high temperatures, they develop tensile stress, which can make them more prone to cracking under impact.

PVD coatings are deposited in a state of compressive stress. This stress state helps to resist the propagation of micro-cracks, further contributing to the insert's overall toughness and chipping resistance.

Selecting the Right Coating for Your Application

Your choice should be dictated entirely by the material you are cutting and the nature of the operation.

- If your primary focus is roughing steel or cast iron at high speeds: Choose a thick, multi-layer CVD coating for its superior heat and abrasive wear resistance.

- If your primary focus is milling, drilling, or cutting stainless steels and superalloys: Opt for a PVD coating to maintain a sharp edge, prevent built-up edge, and provide the toughness needed for interrupted cuts.

- If your primary focus is achieving a high-quality surface finish: A PVD coating is almost always the correct choice due to its ability to preserve the insert's sharp cutting edge.

- If your tool is failing due to chipping rather than slow abrasive wear: You are likely using a CVD insert where a tougher PVD-coated tool is required.

Understanding the fundamental differences between these coating processes empowers you to select tooling that precisely matches the demands of your material and application.

Summary Table:

| Coating Method | Process Temperature | Coating Thickness | Key Characteristics | Best For |

|---|---|---|---|---|

| PVD (Physical Vapor Deposition) | ~500°C (932°F) | Thin, smooth | High toughness, sharp edge, compressive stress | Milling, finishing, stainless steel, interrupted cuts |

| CVD (Chemical Vapor Deposition) | ~1000°C (1832°F) | Thick, multi-layer | Superior wear/heat resistance, tensile stress | High-speed turning, roughing steel/cast iron |

Ready to optimize your machining performance with the right coated carbide inserts?

KINTEK specializes in providing high-quality lab equipment and consumables, including the tools and expertise needed for advanced material processing. Whether your application requires the toughness of a PVD coating or the extreme wear resistance of CVD, we can help you select the perfect solution to increase tool life and productivity.

Contact our experts today for a personalized consultation and discover how KINTEK can enhance your laboratory's capabilities.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating