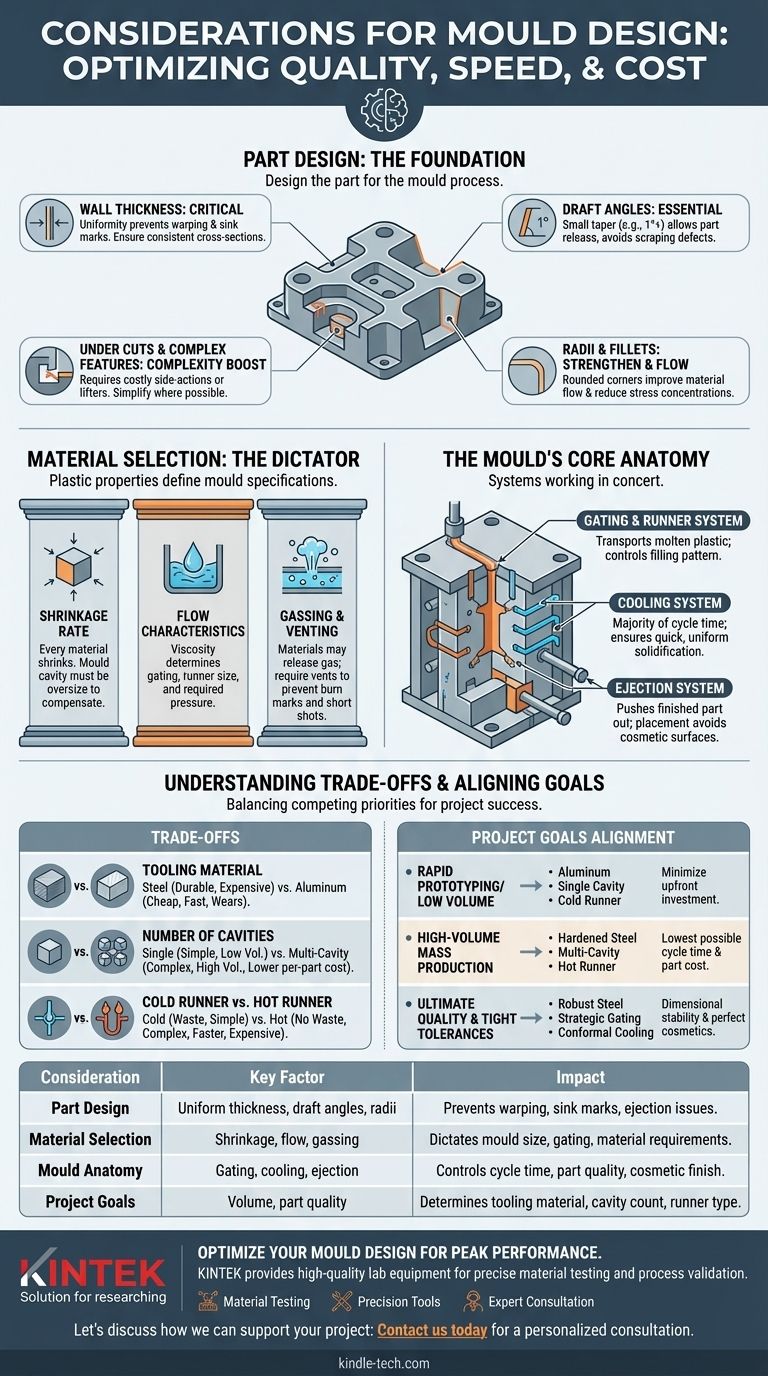

At its core, mould design is a multi-faceted discipline that translates a product design into a repeatable, high-quality manufacturing process. The primary considerations involve a careful balance between the final part's geometry, the properties of the selected plastic material, and the mechanical requirements of the injection moulding machine. Success depends on optimizing for part quality, production speed, and overall cost-effectiveness.

A common misconception is that a mould is simply a negative cavity of a part. In reality, a well-engineered mould is a complex machine in its own right, where every design choice directly impacts production efficiency, final part quality, and the project's bottom line.

Part Design: The Foundation of the Mould

The design of the part itself is the single most important input for the mould design process. Correcting a part design is far cheaper than modifying a finished steel mould.

Wall Thickness

Uniform wall thickness is critical. Inconsistent thickness causes uneven cooling, leading to part warping, sink marks, and internal stresses. The goal is to design parts with the most consistent thickness possible.

Draft Angles

A draft angle is a slight taper applied to the vertical walls of the part. Without it, the part would scrape against the mould surface during ejection, causing cosmetic defects and potentially getting stuck. Even a single degree of draft makes a significant difference.

Undercuts and Complex Features

An undercut is a feature that prevents the part from being ejected directly from the mould. These require mechanisms like side-actions or lifters, which dramatically increase the mould's complexity, cost, and maintenance requirements.

Radii and Fillets

Sharp internal corners create stress concentrations in the part and inhibit the flow of molten plastic. Adding generous radii (rounded corners) strengthens the part, improves material flow, and makes the mould easier to machine.

Material Selection: The Dictator of Design

The specific plastic resin chosen for the part dictates fundamental aspects of the mould's construction. A mould designed for one type of plastic will not work properly with another.

Shrinkage Rate

Every plastic shrinks as it cools from a molten to a solid state. The mould cavity must be machined larger than the final part dimensions to compensate for this. Each material has a unique and often non-uniform shrinkage rate that the designer must precisely calculate.

Flow Characteristics

A material's viscosity determines how easily it flows through the mould. High-viscosity materials may require larger gates, wider runners, and higher injection pressures to fill the cavity completely before solidifying.

Gassing and Venting

Some materials, like PVC, release corrosive gases during moulding. This requires the mould to be built from corrosion-resistant steel and incorporate adequate venting. Vents are tiny channels that allow trapped air and gas to escape the cavity, preventing defects like short shots or burn marks.

The Mould's Core Anatomy

Beyond the part cavity, the mould is an assembly of systems working in concert to produce a finished part.

The Gating and Runner System

The runner is the channel that transports molten plastic from the moulding machine's nozzle to the part cavity. The gate is the specific entry point into the cavity. The location and size of the gate are critical for controlling how the part fills, minimizing cosmetic blemishes, and ensuring structural integrity.

The Ejection System

This system pushes the finished part out of the mould after it has cooled. This is typically done with ejector pins, which can leave small circular marks on the part. The placement of these pins must be carefully considered to act on strong, non-cosmetic areas of the part.

The Cooling System

Cooling accounts for the majority of the injection moulding cycle time. Cooling channels are drilled throughout the mould, and a fluid (usually water) is circulated to control the steel's temperature. An efficient cooling design ensures the part solidifies quickly and uniformly, minimizing cycle time and preventing warpage.

Understanding the Trade-offs

Every decision in mould design involves balancing competing priorities. There is rarely a single "best" solution.

Tooling Material: Steel vs. Aluminum

Hardened steel moulds are durable and can last for millions of cycles, making them ideal for mass production. However, they are expensive and time-consuming to machine. Aluminum moulds are cheaper and faster to create but wear out quickly, making them suitable only for prototyping or very low-volume production.

Number of Cavities

A single-cavity mould produces one part per cycle, keeping the tool simple and inexpensive. A multi-cavity mould produces multiple parts per cycle, lowering the per-part cost but significantly increasing the upfront tooling investment and complexity.

Cold Runner vs. Hot Runner

A cold runner is a simple channel of plastic that solidifies with the part and must be trimmed off and either discarded or recycled. A hot runner is an internally heated system that keeps the plastic molten all the way to the gate, eliminating runner waste and often reducing cycle time, but at a much higher initial cost and complexity.

Aligning Mould Design with Your Project Goals

Your choice of mould design considerations should be driven directly by your ultimate objective.

- If your primary focus is rapid prototyping or low-volume production: Opt for a single-cavity aluminum mould with a simple cold runner and manual features to minimize upfront investment.

- If your primary focus is high-volume mass production: Invest in a multi-cavity hardened steel mould with an optimized cooling system and a hot runner to achieve the lowest possible cycle time and part cost.

- If your primary focus is ultimate part quality and tight tolerances: Prioritize a robust mould structure, strategic gate locations, and conformal cooling to ensure dimensional stability and perfect cosmetics.

A well-designed mould is an asset that pays dividends in quality, speed, and profitability for the entire life of the product.

Summary Table:

| Consideration | Key Factor | Impact |

|---|---|---|

| Part Design | Uniform wall thickness, draft angles, radii | Prevents warping, sink marks, and ejection issues |

| Material Selection | Shrinkage rate, flow characteristics, gassing | Dictates mould size, gating, and material requirements |

| Mould Anatomy | Gating, cooling, and ejection systems | Controls cycle time, part quality, and cosmetic finish |

| Project Goals | Volume (prototype vs. mass production), part quality | Determines tooling material, cavity count, and runner type |

Ready to Optimize Your Mould Design for Peak Performance?

A well-engineered mould is a critical asset for achieving high-quality parts, fast cycle times, and maximum profitability. The right design choices directly impact your project's success, from prototyping to mass production.

At KINTEK, we specialize in providing the high-quality lab equipment and consumables necessary for precise material testing and process validation, serving the critical needs of laboratories in the plastics and manufacturing industries. Our expertise supports your entire workflow, ensuring your mould design is built on a foundation of accurate data and reliable performance.

Let's discuss how we can support your project:

- Material Testing Equipment to validate plastic properties like shrinkage and flow.

- Precision Tools for prototyping and quality control.

- Expert Consultation to align your equipment needs with your production goals.

Contact us today for a personalized consultation and discover how KINTEK's solutions can help you build a better mould, faster.

Visual Guide

Related Products

- Polygon Press Mold for Lab

- Special Shape Press Mold for Lab

- Assemble Lab Cylindrical Press Mold

- Round Bidirectional Press Mold for Lab

- Multi-Punch Rotary Tablet Press Mold Ring for Rotating Oval and Square Molds

People Also Ask

- Is it fitting the mould or mold? A Guide to Correct Spelling by Region

- How do custom graphite molds contribute to Al-20% Si/graphite flake composites? Optimize Microstructure & Conductivity

- What is the physical role of graphite molds in vacuum hot pressing? Optimize Cu-Al2O3 Composite Densification

- Why are custom pressure molds used during the hot pressing process for solid polymer electrolytes?

- What role do high-temperature pressure molds play in SiCp/Al fabrication? Enhancing Densification and Thermal Uniformity