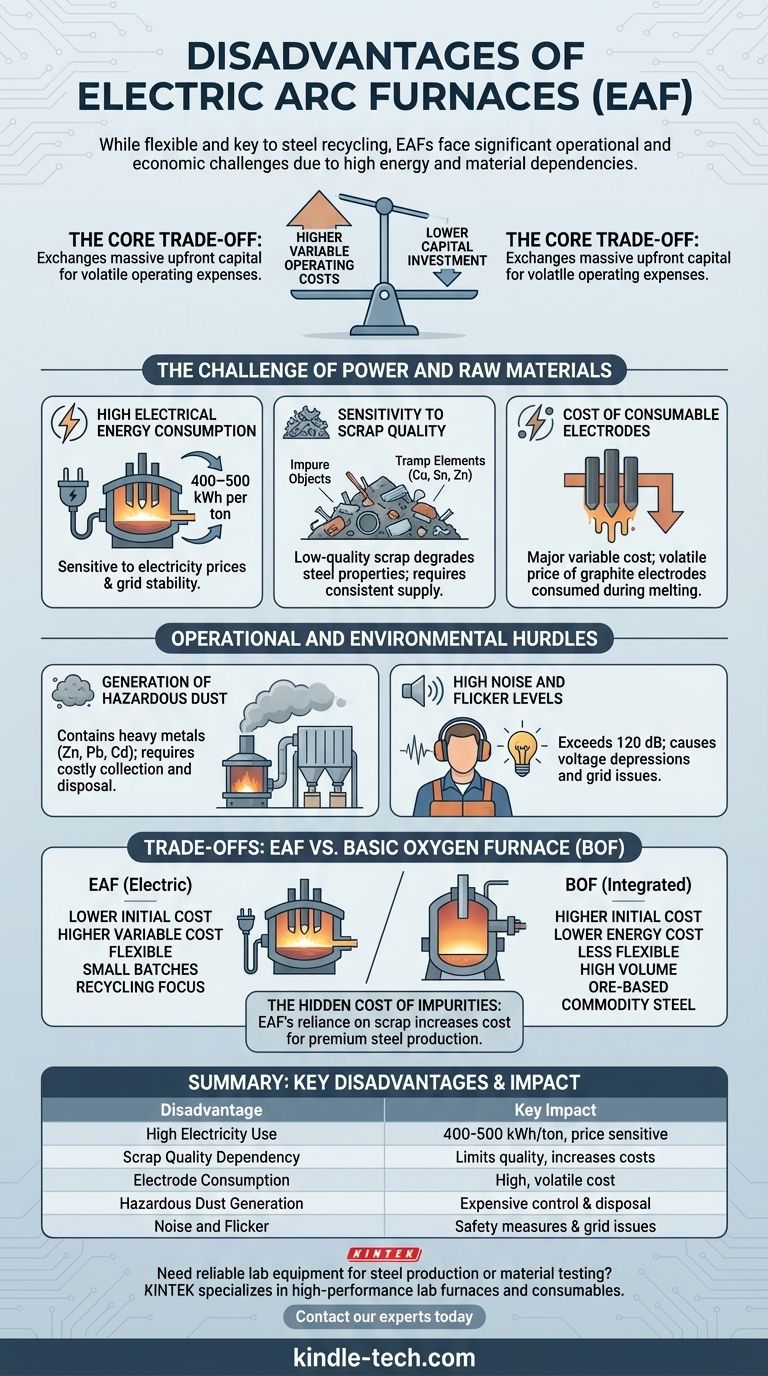

While highly flexible and a cornerstone of modern steel recycling, the Electric Arc Furnace (EAF) is not without significant operational and economic drawbacks. Its primary disadvantages are extremely high electricity consumption, a critical dependency on the quality and cost of scrap steel, and the continuous expense of consumable graphite electrodes. These factors create a distinct set of challenges that must be carefully managed.

The core trade-off of an Electric Arc Furnace lies in its cost structure: it exchanges the massive upfront capital investment of a traditional blast furnace for higher and more volatile variable operating costs, primarily driven by electricity and raw materials.

The Challenge of Power and Raw Materials

The viability of an EAF operation is directly tied to the cost and availability of its two primary inputs: electricity and metallic scrap. This creates dependencies that are often outside a plant operator's control.

High Electrical Energy Consumption

An EAF melts steel using an immense electric arc, making it one of the most power-intensive processes in heavy industry. A typical furnace can consume 400–500 kilowatt-hours (kWh) of electricity per ton of steel produced.

This high consumption makes the furnace's operating cost extremely sensitive to local electricity prices. It also places a significant load on the regional power grid, potentially requiring infrastructure upgrades and exposing the operation to grid instability or demand-based pricing schemes.

Sensitivity to Scrap Quality

EAFs primarily use recycled steel scrap as their main raw material. While this is a major environmental benefit, it introduces a significant process variable: scrap quality.

Low-quality scrap contains residual or "tramp" elements like copper, tin, and zinc. These elements are difficult to remove and can degrade the mechanical properties of the final steel product, limiting its application. Securing a consistent supply of high-quality, low-residual scrap is a constant logistical and financial challenge.

Cost of Consumable Electrodes

The graphite electrodes that generate the arc are a critical and expensive consumable. They are gradually consumed through oxidation and sublimation during the high-temperature melting process.

Electrode consumption is a major component of an EAF's variable costs. The price of high-quality graphite electrodes can be volatile, directly impacting the profitability per ton of steel.

Operational and Environmental Hurdles

Beyond input costs, the EAF process itself generates byproducts and conditions that require significant investment in control and mitigation systems.

Generation of Hazardous Dust

The intense heat and violent reactions within the furnace vaporize metals, which then oxidize and form a fine particulate known as EAF dust. This dust is classified as a hazardous waste because it contains heavy metals like zinc, lead, and cadmium.

Managing EAF dust requires extensive and costly environmental control systems, such as large baghouses for collection. Proper disposal or recycling of this hazardous material represents a significant and permanent operating expense.

High Noise and Flicker Levels

The electric arc is intensely loud, with noise levels regularly exceeding 120 decibels. This necessitates sound-proof enclosures for the furnace and hearing protection for all personnel in the vicinity to comply with occupational health and safety standards.

Furthermore, the massive and fluctuating power draw can cause voltage depressions on the electrical grid, a phenomenon known as flicker, which can affect other users on the same network.

Understanding the Trade-offs

The disadvantages of an EAF are best understood when compared to its primary alternative, the Basic Oxygen Furnace (BOF) used in traditional integrated steel mills.

Cost Structure vs. Basic Oxygen Furnace (BOF)

An EAF plant has a much lower initial capital cost than an integrated mill, which requires a coke plant, blast furnace, and BOF.

However, the EAF has higher variable costs per ton, driven by electricity and electrodes. A BOF, which generates heat through chemical reactions, has lower energy costs and uses cheaper raw materials like iron ore and hot metal, making it more cost-effective for high-volume production.

Production Volume and Flexibility

EAFs are highly flexible. They can be started and stopped relatively easily, making them ideal for producing smaller batches and specialized steel grades in response to market demand.

A BOF, in contrast, is designed for continuous, large-scale production of commodity steel grades. It is far less flexible and operates most efficiently when running at or near full capacity around the clock.

The Hidden Costs of Impurities

While an EAF excels at recycling, the reliance on scrap means a constant battle against impurities. The cost of sourcing premium scrap or implementing extra refining steps to remove tramp elements can quickly erode the EAF's economic advantages. A BOF, starting with purified iron ore, offers much greater control over final steel chemistry.

Making the Right Choice for Your Goal

Selecting the right furnace technology depends entirely on your strategic objectives, market conditions, and geographic location.

- If your primary focus is minimizing initial investment and maximizing flexibility: The EAF is the superior choice, but you must model for high and potentially volatile operating costs.

- If your primary focus is producing very high volumes of commodity steel: A large, integrated Basic Oxygen Furnace plant is likely more economical, provided you have access to iron ore and coking coal.

- If your primary focus is environmental stewardship and using recycled materials: The EAF is the clear leader, as it avoids the massive CO2 footprint of a blast furnace and turns scrap into a valuable resource.

Understanding these disadvantages allows you to accurately model the true cost and operational reality of an electric arc furnace for your specific needs.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| High Electricity Use | 400-500 kWh per ton, sensitive to power prices |

| Scrap Quality Dependency | Limits final steel quality, increases costs |

| Electrode Consumption | High, volatile cost of graphite electrodes |

| Hazardous Dust Generation | Requires expensive control and disposal systems |

| Noise and Flicker | Needs safety measures and grid stability solutions |

Need reliable lab equipment to support your steel production or material testing? KINTEK specializes in high-performance lab furnaces, consumables, and analytical tools tailored for metallurgical labs. Whether you're optimizing EAF operations or researching new alloys, our solutions enhance precision, efficiency, and safety. Contact our experts today to find the right equipment for your laboratory needs!

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- Why does heating increase temperature? Understanding the Molecular Dance of Energy Transfer

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- What is a vertical tube furnace? Leverage Gravity for Superior Uniformity and Process Control

- What is the process of annealing tubes? Achieve Optimal Softness and Ductility for Your Tubing

- What is the temperature of a quartz tube furnace? Master the Limits for Safe, High-Temp Operation