Ultimately, the primary disadvantages of fluidized beds stem from their own dynamic nature. While they offer superior mixing and heat transfer, this same high-energy particle motion leads to significant equipment erosion, loss of bed material, and complex operational demands that are not present in fixed-bed or moving-bed systems.

The core trade-off of fluidized bed technology is accepting higher operational complexity and equipment wear in exchange for exceptional heat/mass transfer and temperature uniformity. Understanding this balance is critical to determining if it's the right choice for your application.

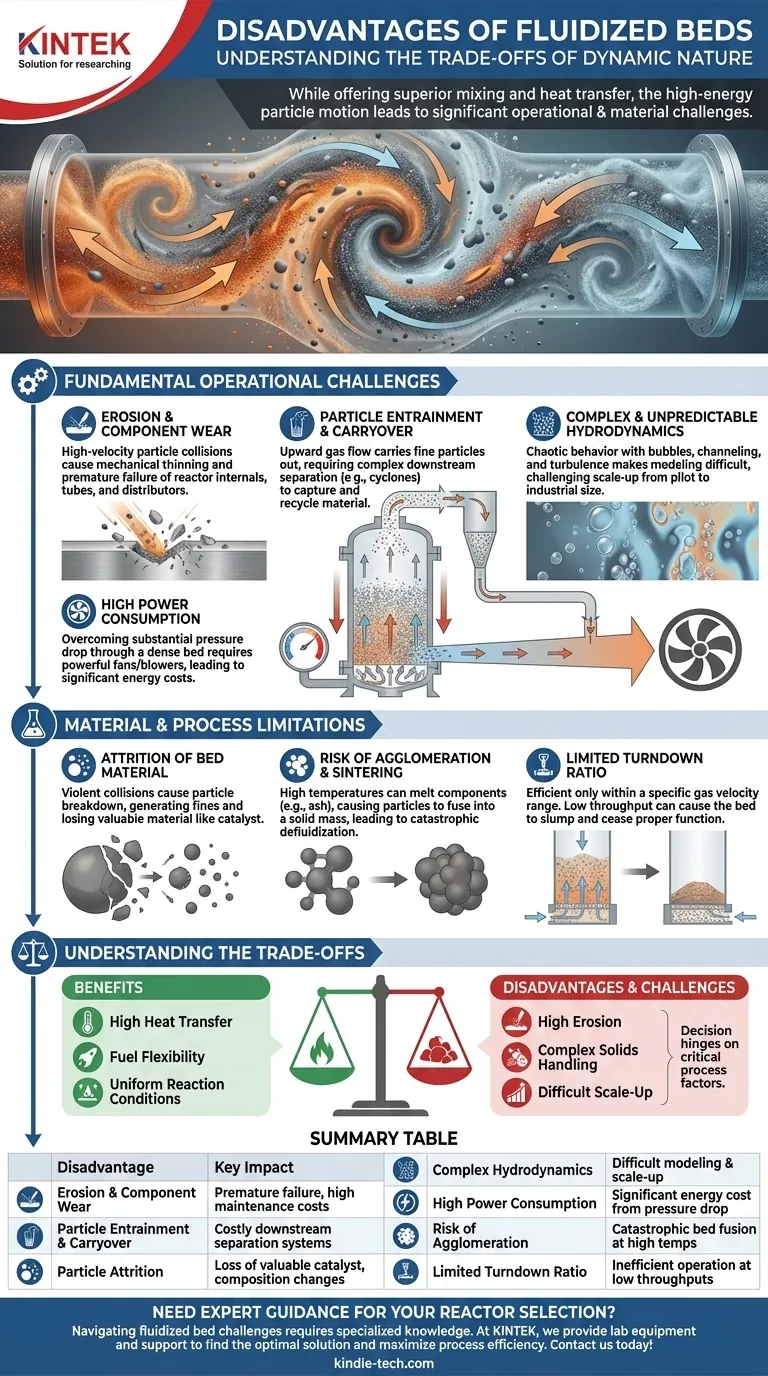

Fundamental Operational Challenges

The physics of creating and maintaining a fluidized state introduces several inherent difficulties that must be engineered around. These are not flaws in a specific design but characteristics of the technology itself.

Erosion and Component Wear

High-velocity solid particles constantly collide with the internal surfaces of the reactor, heat exchanger tubes, and gas distributors. This abrasive action causes significant mechanical erosion, thinning materials over time and leading to premature equipment failure. This is often the most significant maintenance concern.

Particle Entrainment and Carryover

The upward flow of gas that fluidizes the bed will inevitably carry the finest particles out of the reactor. This entrainment requires extensive downstream gas-solid separation systems, such as cyclones, to capture and often recycle the lost material. This adds capital cost, complexity, and a potential source of failure.

Complex and Unpredictable Hydrodynamics

The gas-solid mixture in a fluidized bed is not a uniform, gentle fluid. It is characterized by bubbles, channeling, and turbulent, chaotic motion. This behavior is notoriously difficult to model and predict accurately, which makes scaling a design from a small pilot plant to a large industrial unit a significant engineering challenge.

High Power Consumption

Forcing gas through a dense bed of solids creates a substantial pressure drop. Overcoming this requires powerful fans or blowers, which represent a continuous and significant operational energy cost, often referred to as a "parasitic load."

Material and Process Limitations

Beyond the operational physics, the materials being used in the bed and the process conditions can create further disadvantages.

Attrition of Bed Material

The constant, violent collisions between particles cause them to break down or wear away, a process known as attrition. This generates more fine particles (worsening entrainment), changes the overall particle size distribution of the bed, and results in a loss of valuable material, such as an expensive catalyst.

Risk of Agglomeration and Sintering

In high-temperature applications like combustion or gasification, components within the fuel (like ash) can melt at operating temperatures. This creates sticky particles that can cause the entire bed to fuse into a single solid mass, a catastrophic failure mode known as agglomeration or defluidization.

Limited Turndown Ratio

Fluidized beds operate efficiently only within a specific range of gas velocities. If the process requires operating at significantly lower throughputs (a high "turndown ratio"), the gas velocity may fall too low to maintain proper fluidization, causing the bed to slump and cease functioning correctly.

Understanding the Trade-offs

Choosing a fluidized bed reactor means consciously accepting its downsides to gain its powerful benefits. The decision often hinges on which factors are most critical for your specific process.

High Heat Transfer vs. High Erosion

You gain exceptionally uniform temperature profiles and rapid heat transfer, which is ideal for highly exothermic or endothermic reactions. The cost is the constant erosive wear on internal components, which demands robust materials and a rigorous maintenance schedule.

Fuel Flexibility vs. Complex Solids Handling

A key advantage, particularly in boilers, is the ability to use low-quality, heterogeneous fuels like biomass or waste. The trade-off is the need to manage the consequences, such as ash-induced agglomeration and the handling of large quantities of solid material.

Uniform Reaction Conditions vs. Difficult Scale-Up

The excellent mixing provides uniform reaction conditions, which can improve product yield and selectivity. However, you must accept the risk and engineering effort required to scale up a system with such complex, non-linear hydrodynamics.

Making the Right Choice for Your Goal

To decide if a fluidized bed is appropriate, you must weigh its disadvantages against your primary objective.

- If your primary focus is minimizing maintenance and maximizing equipment lifespan: The high erosion rates associated with fluidized beds present a significant liability.

- If your primary focus is process simplicity and predictability: The complex hydrodynamics and challenging scale-up make this a less desirable technology.

- If you are working with friable or expensive catalyst materials: The constant attrition and potential loss of fines through entrainment could make this technology cost-prohibitive.

- If your process requires very wide operating ranges (high turndown): The limited turndown ratio of a fluidized bed could be a critical operational constraint compared to other systems.

Fluidized bed technology provides unparalleled performance in specific applications, but its benefits are inextricably linked to significant operational and material challenges.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Erosion & Component Wear | Premature equipment failure, high maintenance costs |

| Particle Entrainment & Carryover | Requires costly downstream separation systems |

| Particle Attrition | Loss of valuable catalyst, changes in bed composition |

| Complex Hydrodynamics | Difficult to model and scale up from pilot plants |

| High Power Consumption | Significant energy cost from pressure drop |

| Risk of Agglomeration | Catastrophic bed fusion at high temperatures |

| Limited Turndown Ratio | Inability to operate efficiently at low throughputs |

Struggling with reactor selection for your lab process? The challenges of fluidized beds—like erosion, attrition, and complex operation—require expert guidance. At KINTEK, we specialize in lab equipment and consumables, helping you navigate these trade-offs to find the optimal solution for your specific application. Our team can provide the right equipment and support to maximize your process efficiency and minimize downtime. Contact us today via our contact form to discuss your laboratory needs and discover how KINTEK can enhance your research and development outcomes.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- High Performance Laboratory Freeze Dryer for Research and Development

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- What temperature is a carbon regeneration kiln? Master the 650°C-800°C Range for Optimal Results

- Where are rotary kilns used? The Heart of Industrial Processing for Cement, Metals & More

- What is a rotary kiln used for? Mastering Uniform High-Temperature Processing

- What is pyrolysis heating rate? The Key to Controlling Biochar, Bio-oil, and Syngas Yields

- How is calcination process performed? Master Thermal Decomposition for Industrial Applications

- What is the temperature of microwave pyrolysis? Achieve Precise Thermal Decomposition

- What is the process of thermal pyrolysis? A Step-by-Step Guide to Chemical Recycling

- How much CO2 is released from calcination? The Inescapable 44% Mass Loss from Limestone