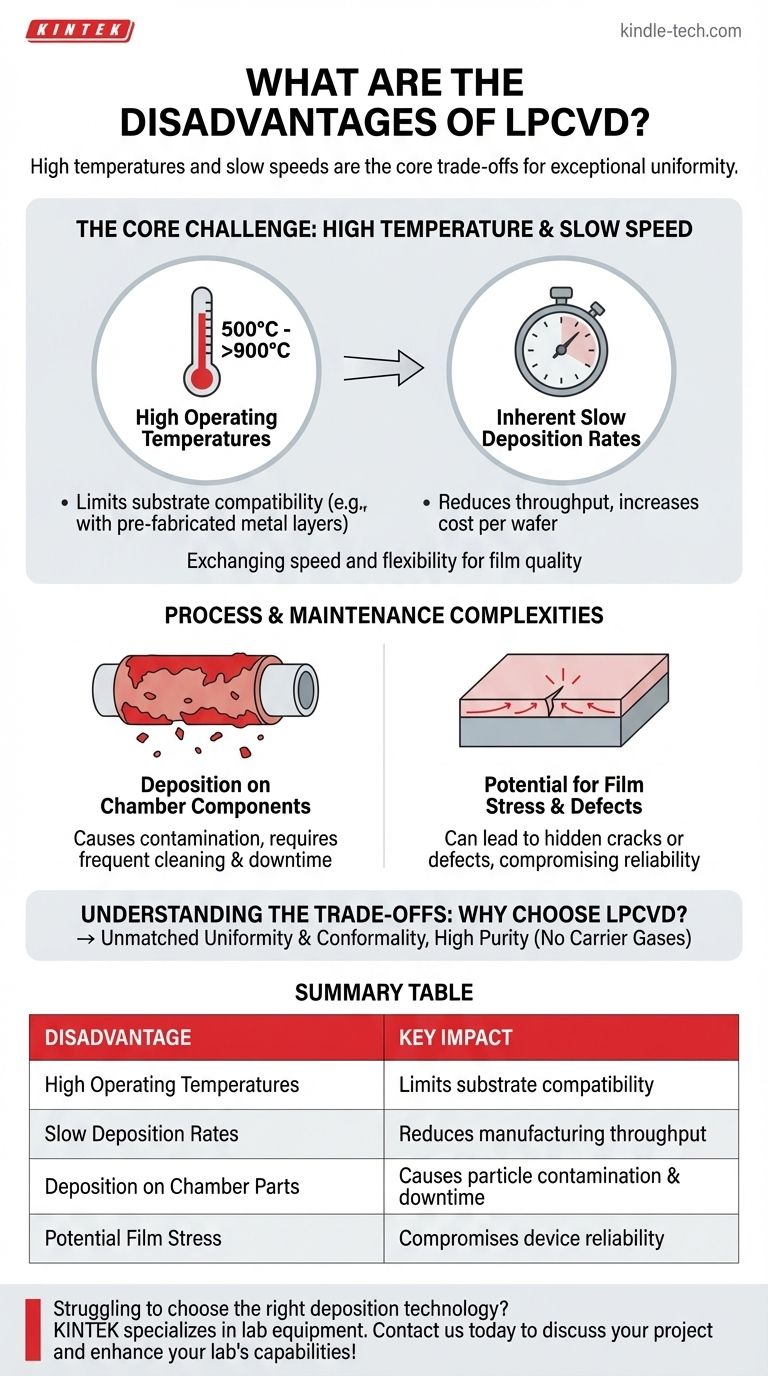

The primary disadvantages of Low-Pressure Chemical Vapor Deposition (LPCVD) are its high operating temperatures, which limit substrate compatibility, and its inherently slow deposition rates, which reduce manufacturing throughput. These are compounded by process challenges like unwanted deposition on chamber components and potential for film stress.

While often considered a workhorse for high-quality thin films, LPCVD's disadvantages are not flaws but fundamental trade-offs. You are essentially exchanging processing speed and flexibility for exceptional film uniformity, purity, and the ability to coat complex topographies.

The Core Challenge: High Temperature and Slow Speed

The defining characteristics of the LPCVD process—low pressure and high heat—are the source of both its greatest strengths and its most significant drawbacks.

The Impact of High Temperatures

LPCVD processes typically operate at high temperatures, often in the range of 500°C to over 900°C. This high thermal budget creates a critical limitation.

It makes the process unsuitable for depositing films on substrates that cannot withstand such heat, such as those with previously fabricated metal layers (like aluminum) or temperature-sensitive materials.

Inherent Slow Deposition Rates

The low-pressure environment, while excellent for uniformity, contributes to a slower reaction rate compared to atmospheric pressure methods.

This directly impacts manufacturing throughput. For applications requiring thick films or high-volume production, the slow speed of LPCVD can become a significant bottleneck and increase the cost per wafer.

Process and Maintenance Complexities

Beyond the core operational characteristics, the practical implementation of LPCVD introduces further challenges that must be managed.

Deposition on Chamber Components

The chemical vapor precursors in an LPCVD system are not selective; they will deposit a film on any surface that is hot enough.

This leads to significant coating of the quartz furnace tube and other internal parts. This unwanted deposition can flake off, creating particle contamination that reduces yield, and necessitates frequent, time-consuming cleaning cycles, leading to equipment downtime.

Potential for Film Stress and Defects

The high temperatures involved in deposition and the subsequent cooling cycle can induce significant thermal stress between the newly deposited film and the underlying substrate.

If not properly managed, this stress can lead to the formation of "hidden cracks" or other film defects, compromising the integrity and reliability of the device.

Challenges with In-Situ Doping

While doping the film during the deposition process (in-situ) is possible, it can be difficult to control. Achieving uniform dopant concentration throughout the film and across the wafer batch can be more complex in an LPCVD system compared to post-deposition methods like ion implantation.

Understanding the Trade-offs: Why Choose LPCVD?

To fully grasp the disadvantages, one must weigh them against the unique advantages that make LPCVD a critical process in semiconductor manufacturing.

The Goal: Unmatched Uniformity and Conformality

LPCVD excels at producing films with outstanding thickness uniformity and conformality (the ability to evenly coat complex, three-dimensional structures like trenches).

The low pressure increases the mean free path of gas molecules, allowing them to reach and coat all surfaces of a complex topography before reacting. This is the primary reason LPCVD is chosen for critical layers like polysilicon gates and silicon nitride passivation.

The Purity Advantage

The process does not require carrier gases, and the low-pressure environment allows reaction by-products to be removed efficiently. This results in films with very high purity and low particle contamination, which is essential for high-performance electronic devices.

Context vs. Other Methods

Every deposition method has its own set of compromises. For example, while Metal-Organic CVD (MOCVD) can be used for different materials, its precursors are often extremely expensive, toxic, and hazardous. LPCVD, despite its drawbacks, is a mature and relatively well-understood process.

Making the Right Choice for Your Application

Selecting a deposition technique requires aligning the process capabilities with your primary engineering goal.

- If your primary focus is exceptional film quality and conformality: LPCVD is often the best choice, provided your substrate can tolerate the high temperatures and your production model can accommodate the slower speed.

- If your primary focus is high throughput on temperature-sensitive substrates: You should explore alternatives like Plasma-Enhanced CVD (PECVD), which operates at much lower temperatures and higher deposition rates.

- If your primary focus is atomic-level precision and control: Consider Atomic Layer Deposition (ALD), which offers unparalleled conformality and thickness control, albeit at even slower speeds than LPCVD.

Understanding these inherent limitations allows you to leverage LPCVD for its unparalleled strengths in the precise applications where quality and uniformity are non-negotiable.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| High Operating Temperatures | Limits substrate compatibility (e.g., with pre-fabricated metal layers) |

| Slow Deposition Rates | Reduces manufacturing throughput, increases cost per wafer |

| Deposition on Chamber Parts | Causes particle contamination, requires frequent cleaning and downtime |

| Potential Film Stress | Can lead to hidden cracks or defects, compromising device reliability |

Struggling to choose the right deposition technology for your specific application? KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you navigate the trade-offs between LPCVD, PECVD, and ALD to find the optimal solution for your film quality, throughput, and substrate requirements. Contact us today to discuss your project and enhance your lab's capabilities!

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are the advantages of industrial CVD for solid boriding? Superior Process Control and Material Integrity

- What function does CVD equipment serve in rhodium-modified coatings? Achieve Deep Diffusion and Microstructural Precision

- How does chirality affect carbon nanotubes? It Determines If They Are Metal or Semiconductor

- What is a CVD tube furnace? A Complete Guide to Thin-Film Deposition

- How high of temperature do carbon nanotubes in air have the ability to sustain? Understanding the Oxidation Limit