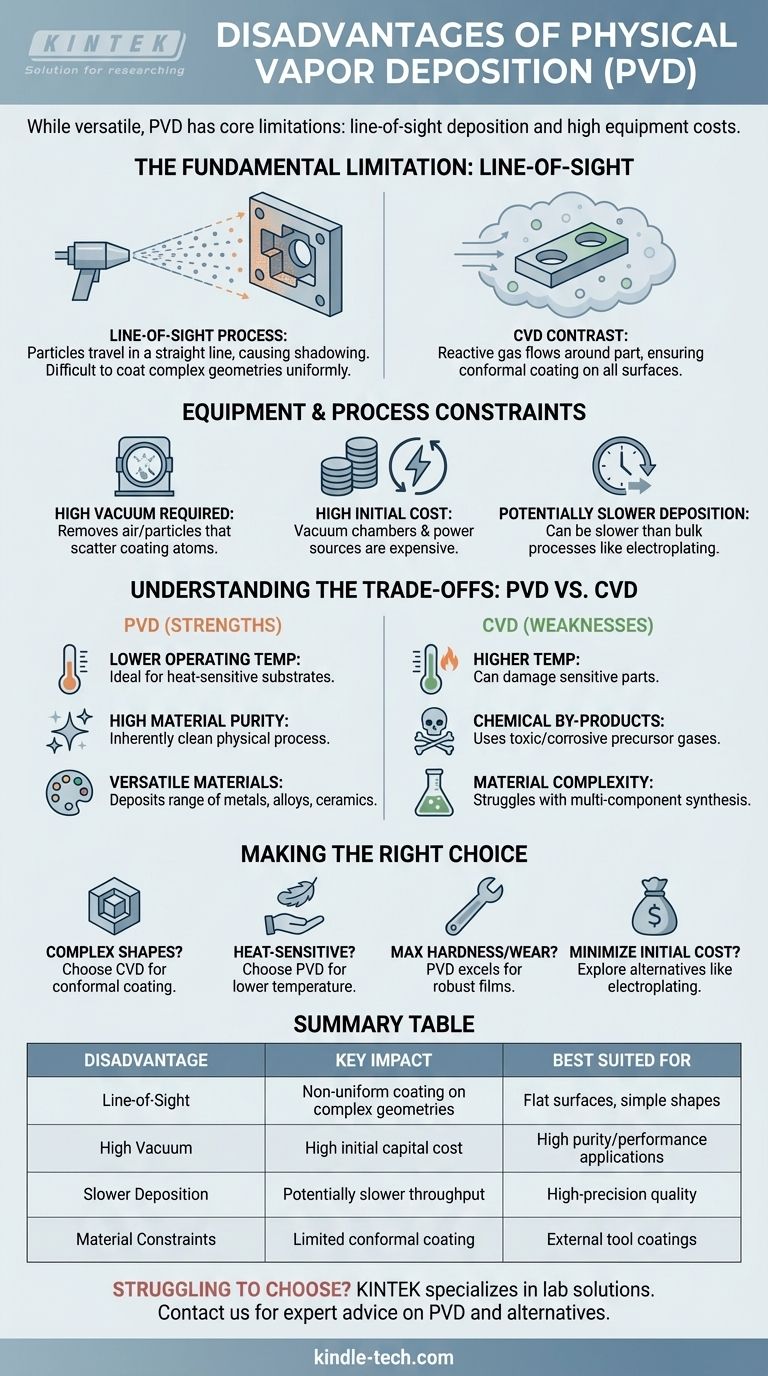

While a versatile and widely used technique, the primary disadvantages of Physical Vapor Deposition (PVD) are its line-of-sight nature, which makes it difficult to coat complex geometries uniformly, and the high initial cost and complexity of its vacuum-based equipment. These limitations contrast with its key benefits, such as lower operating temperatures and higher material purity compared to other methods.

The disadvantages of PVD are not failures of the technology, but rather inherent trade-offs. Its reliance on a physical line-of-sight process makes it excellent for producing pure, dense films on flat surfaces but challenging for coating intricate shapes.

The Fundamental Limitation: Line-of-Sight Deposition

The core challenge of PVD stems from how the coating material travels from its source to the target surface.

What "Line-of-Sight" Means

In a PVD process like sputtering or evaporation, atoms are ejected from a source material and travel in a straight line through a vacuum until they strike the substrate. Think of it like a can of spray paint—only the surfaces directly facing the nozzle get a thick, even coat.

The Problem with Complex Geometries

This straight-line travel creates a "shadowing" effect. Areas that are not in the direct line of sight of the source material, such as the inside of a tube, holes, or the underside of a complex part, will receive little to no coating. This results in non-uniform film thickness and inconsistent performance.

Contrast with CVD's "Throwing Power"

This is a key differentiator from Chemical Vapor Deposition (CVD). In CVD, a reactive gas flows around the substrate. The gas can penetrate into complex features and react on all exposed surfaces, resulting in a much more uniform, or "conformal," coating.

Equipment and Process Constraints

The physical requirements for a successful PVD process introduce another set of challenges related to cost and operational complexity.

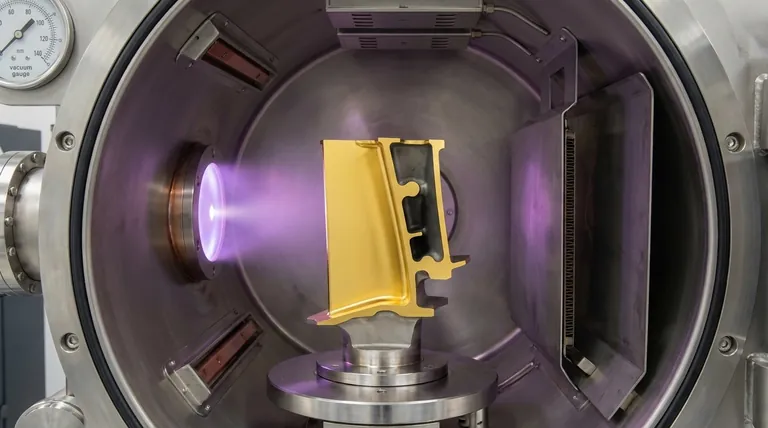

The Need for High Vacuum

PVD must be performed in a high-vacuum chamber. This vacuum is necessary to remove air and other particles that would otherwise collide with and scatter the coating atoms, preventing them from reaching the substrate.

High Initial Capital Cost

Vacuum chambers, high-power sources for evaporation or sputtering, and sophisticated pumping systems make PVD equipment expensive to purchase and install. This high barrier to entry can make it unsuitable for smaller-scale or lower-budget operations.

Potentially Slower Deposition Rates

While highly dependent on the specific material and method, PVD can sometimes have lower deposition rates compared to other bulk processes like electroplating or certain high-speed CVD techniques. This can impact manufacturing throughput for high-volume applications.

Understanding the Trade-offs: PVD vs. CVD

The disadvantages of PVD are best understood when compared to its primary alternative, Chemical Vapor Deposition. The drawbacks of one are often the strengths of the other.

Operating Temperature

PVD is a lower-temperature process than most CVD methods. The high temperatures required for CVD, as noted in the references, can damage or warp sensitive substrates. PVD's lower temperature range makes it ideal for coating plastics, certain alloys, and other materials that cannot withstand thermal stress.

Material Purity and By-products

PVD is an inherently clean physical process that transfers a solid source material onto a substrate. In contrast, CVD relies on chemical reactions with precursor gases that are often toxic, corrosive, and expensive. CVD also produces hazardous by-products that require costly and complex disposal.

Material Versatility and Composition

PVD methods are extremely versatile and can be used to deposit a vast range of metals, alloys, and ceramics. The references note that CVD struggles with synthesizing multi-component materials due to variations in chemical reaction rates, a problem that PVD largely avoids by physically depositing the source material.

Making the Right Choice for Your Application

Selecting the correct deposition technology requires matching your primary goal to the fundamental strengths of the process.

- If your primary focus is coating complex 3D shapes or internal surfaces: CVD is often the superior choice due to its ability to conformally coat all exposed areas.

- If your primary focus is applying a high-purity, dense coating on a heat-sensitive substrate: PVD is the better option because it operates at lower temperatures and avoids chemical contamination.

- If your primary focus is achieving maximum hardness and wear resistance on a line-of-sight surface: PVD excels at creating these robust films for tools, optics, and aerospace components.

- If your primary focus is minimizing initial equipment cost for a thermally robust part: Exploring alternatives like CVD or electroplating may be more economical, provided you can manage the associated chemical handling or performance trade-offs.

Ultimately, choosing the right method requires evaluating your component's geometry and material properties against the core principles of each technique.

Summary Table:

| Disadvantage | Key Impact | Best Suited For |

|---|---|---|

| Line-of-Sight Deposition | Non-uniform coating on complex geometries; shadowing effects | Flat surfaces, simple shapes, line-of-sight applications |

| High Vacuum Equipment | High initial capital cost; complex setup and maintenance | Applications requiring high purity and performance |

| Lower Deposition Rates | Potentially slower throughput compared to some alternatives | High-precision coatings where quality outweighs speed |

| Material & Geometry Constraints | Limited conformal coating; not ideal for internal surfaces | External coatings on tools, optics, and wear-resistant parts |

Struggling to choose the right coating technology for your lab's specific needs? The trade-offs between PVD and other methods like CVD can be complex. At KINTEK, we specialize in lab equipment and consumables, helping you navigate these decisions to optimize your processes. Whether you need high-purity PVD coatings for heat-sensitive materials or advice on alternative methods, our experts are here to help. Contact us today to discuss your application and discover the ideal solution for your laboratory requirements.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Anti-Cracking Press Mold for Lab Use

People Also Ask

- How does hot pressing work? Achieve Maximum Density for Advanced Materials

- What is the purpose of laminating? Protect and Enhance Your Documents for Long-Term Use

- What are the advantages and disadvantages of hot pressing? Choose the Right Powder Metallurgy Process

- What are the advantages and disadvantages of hot stamping? Unlock Ultra-High Strength for Automotive Parts

- Why is a vacuum hot-pressing furnace preferred for C_fiber/Si3N4 composites? Achieve High Density & Fiber Protection